42

NORMAL OPERATION

The icemaker always starts from and stops at the “park” position. In the park position the

ejector blades are pointing horizontally towards the back of the icemaker. Just before

reaching the park position the mold is filled with water. At the park position all electrical

components are de-energized, even though the shut-off arm is down, and the icemaker is

ready for the next freeze cycle.

The icemaker takes from 30 minutes to one hour to freeze the water. The primary time

factors are the temperature in the freezer and the amount of airflow around the icemaker.

Colder freezer settings and free air space around the icemaker to let air circulate will help

make ice faster.

After the ice forms, the icemaker continues to wait until it reaches 15º F before it starts

the harvest cycle. This insures that the ice is solid in all the cavities. At 15º F the

thermostat closes, the mold heater turns on, and the ejector blades rotate up and forward

until they stall out against the ice. The motor is designed to stall out and is geared to

generate a lot of pressure. This minimizes the amount of melting needed to extract the

ice. As soon as the ice is loose enough to move, the ejector pushes the ice out of the

mold during the second half of the first revolution. During the second revolution the

ejector pushes the ice into the bucket. Just before the ejector completes the second

revolution the icemaker turns the water valve on for approximately 7 seconds and refills

the mold with approximately 4 ounces of water and the freezing cycle is ready to begin

again.

TROUBLESHOOTING

Replace if necessary….

BUT DON’T REPLACE UNTIL YOU ARE SURE IT IS

THE ICEMAKER.

Here’s how to tell: To make ice, an icemaker needs power, water,

and sub-freezing temperatures.

ELECTRICAL POWER

NOTE: The freezer door switch turns off power to the icemaker when the freezer door is

open. It will be necessary to manually close the freezer door switch for some

troubleshooting steps.

1.

Check that the shut-off arm is down and instruct customer on its use if

necessary.

2.

Quick check for power without a test device. Manually rotate the ejector up

and forward (clockwise viewed from the motor end) by 1/8 to 1/4 turn or

remove the cover and rotate the small motor drive gear counter-clockwise

with a screwdriver. With hands clear of the icemaker, manually close the

freezer door switch. If the ejector begins to rotate (very slowly) there is

power. If the ejector does not rotate, go on to Step 3.

3.

Checking for power with a test device: See figure 4. unplug the icemaker and

connect a test light or a voltmeter to the top and bottom terminals of the 4-

pole connector socket. Manually close the freezer door switch. If there is

power, check for water next. If there is not power at the icemaker connector,

trace power from the wall socket to the door switch to the connector. (Con’t)

Summary of Contents for Designer DDFB304

Page 1: ...F90612...

Page 2: ...F90612 VIKING RANGE CORPORATION P O DRAWER 956 GREENWOOD MS 38930 USA...

Page 22: ...21 Wiring Schematic 30 W All Freezer...

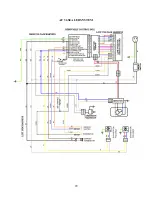

Page 23: ...22 AF 30 LIGHT CIRCUITS...

Page 24: ...23 AF 30 120V CIRCUIT...

Page 25: ...24 AF 30 SEALED SYSTEM...

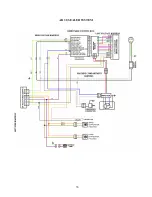

Page 26: ...25 AF 30 ICEMAKER CIRCUIT...

Page 27: ...26 Wiring Schematic 36 W All Freezer...

Page 28: ...27 AF 36 LIGHT CIRCUITS...

Page 29: ...28 AF 36 120V CIRCUIT...

Page 30: ...29 AF 36 SEALED SYSTEM...

Page 31: ...30 AF 36 ICEMAKER CIRCUIT...

Page 32: ...31 Wiring Schematic 30 W All Refrigerator...

Page 33: ...32 AR 30 120V INPUT AR 30 LIGHT CIRCUITS...

Page 34: ...33 AR 30 SEALED SYSTEM...

Page 35: ...34 Wiring Schematic 36 W All Refrigerator...

Page 36: ...35 AR 36 120V INPUT AR 36 LIGHT CIRCUITS...

Page 37: ...36 AR 36 SEALED SYSTEM...

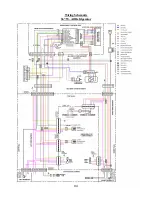

Page 39: ...38 ALL MODELS New Control Boards with adapter functionality...

Page 40: ...39...

Page 48: ...47 SEALED SYSTEM...