43

Icemaker (Continued)

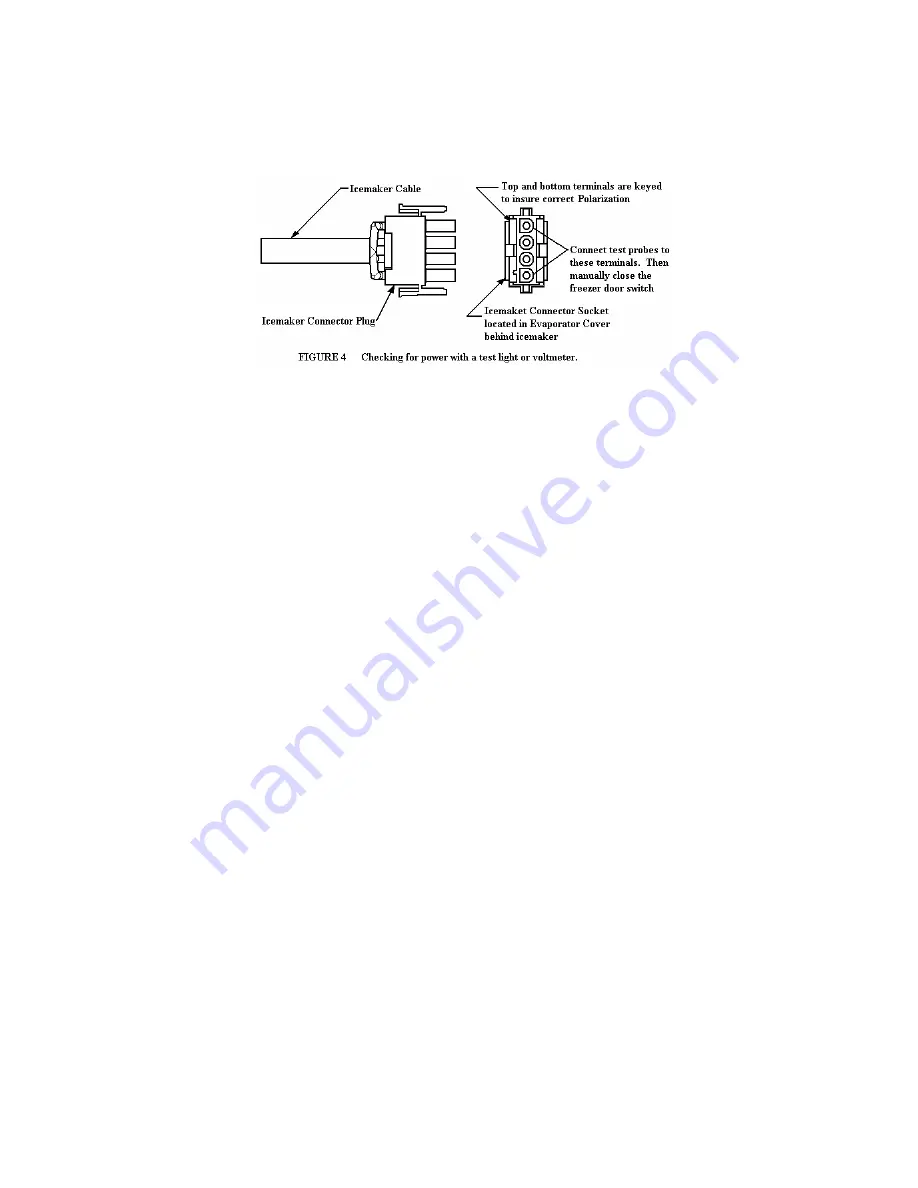

Repair circuit and connections or replace door switch as needed. When there is power,

recheck icemaker operation. If there is still not ice, check for water problems next.

WATER PROBLEMS

CAUTION:

Do not use a Reverse Osmosis Water Filtration System. It reduces the

water pressure below 20 psi and the icemaker will not fill. Use of a Reverse Osmosis

system will void the warranty.

Poor water quality can cause icemaker to fail or produce unacceptable cubes. Install a

water filter to eliminate bad taste, odor, and visible contaminates. Mineral content or

sand can restrict screen in water fill valve or particles of sand can keep valve from seating

properly. If water valve does not operate properly, the following could occur:

•

No ice production

•

Small or hollow ice cubes

•

Flooding of ice container

Mineral content can cause lime build up in the mold, wicking of water over the mold and

poor cube release. Mineral content can also restrict saddle valves.

WATER SUPPLY

1.

Water supply is turned OFF. Turn water supply line ON.

2.

Water pressure too low (below 20 psi). Check pressure at source. If OK, look

for obstructions or restrictions as follows.

3.

Saddle valve not fully open. Open valve fully.

4.

Saddle valve fully opened but still restricted. Quick fix: Fully close and

reopen to dislodge sediment. If necessary, remove valve and enlarge pierced

hole to 3/16” diameter with a drill and reinstall saddle valve.

5.

Water line to unit pinched/kinked/clogged. Repair water line.

6.

Ice in inlet tube blocking water flow. Remove ice from tube.

7.

Water pressure too high (above 120 psi). Install pressure regulator.

WATER FILL LEVEL

NOTE:

The water fill level adjustment screw is located under the motor cover. See

Figures 2 and 3. the icemaker mounting brackets gave built-in differences so that the

motor end will be slightly below (1/2º) the water fill end. See Figure 5. The purpose is

to help the water fill all the cavities with slight excess at the motor end where the

thermostat is located. This insures the motor end is the last to reach 15º F. This prevents

early cycling which results in hollow ice cubes.

Summary of Contents for Designer DDFB304

Page 1: ...F90612...

Page 2: ...F90612 VIKING RANGE CORPORATION P O DRAWER 956 GREENWOOD MS 38930 USA...

Page 22: ...21 Wiring Schematic 30 W All Freezer...

Page 23: ...22 AF 30 LIGHT CIRCUITS...

Page 24: ...23 AF 30 120V CIRCUIT...

Page 25: ...24 AF 30 SEALED SYSTEM...

Page 26: ...25 AF 30 ICEMAKER CIRCUIT...

Page 27: ...26 Wiring Schematic 36 W All Freezer...

Page 28: ...27 AF 36 LIGHT CIRCUITS...

Page 29: ...28 AF 36 120V CIRCUIT...

Page 30: ...29 AF 36 SEALED SYSTEM...

Page 31: ...30 AF 36 ICEMAKER CIRCUIT...

Page 32: ...31 Wiring Schematic 30 W All Refrigerator...

Page 33: ...32 AR 30 120V INPUT AR 30 LIGHT CIRCUITS...

Page 34: ...33 AR 30 SEALED SYSTEM...

Page 35: ...34 Wiring Schematic 36 W All Refrigerator...

Page 36: ...35 AR 36 120V INPUT AR 36 LIGHT CIRCUITS...

Page 37: ...36 AR 36 SEALED SYSTEM...

Page 39: ...38 ALL MODELS New Control Boards with adapter functionality...

Page 40: ...39...

Page 48: ...47 SEALED SYSTEM...