© 2010 Viking Preferred Service

38

Service Diagnostics and Procedures

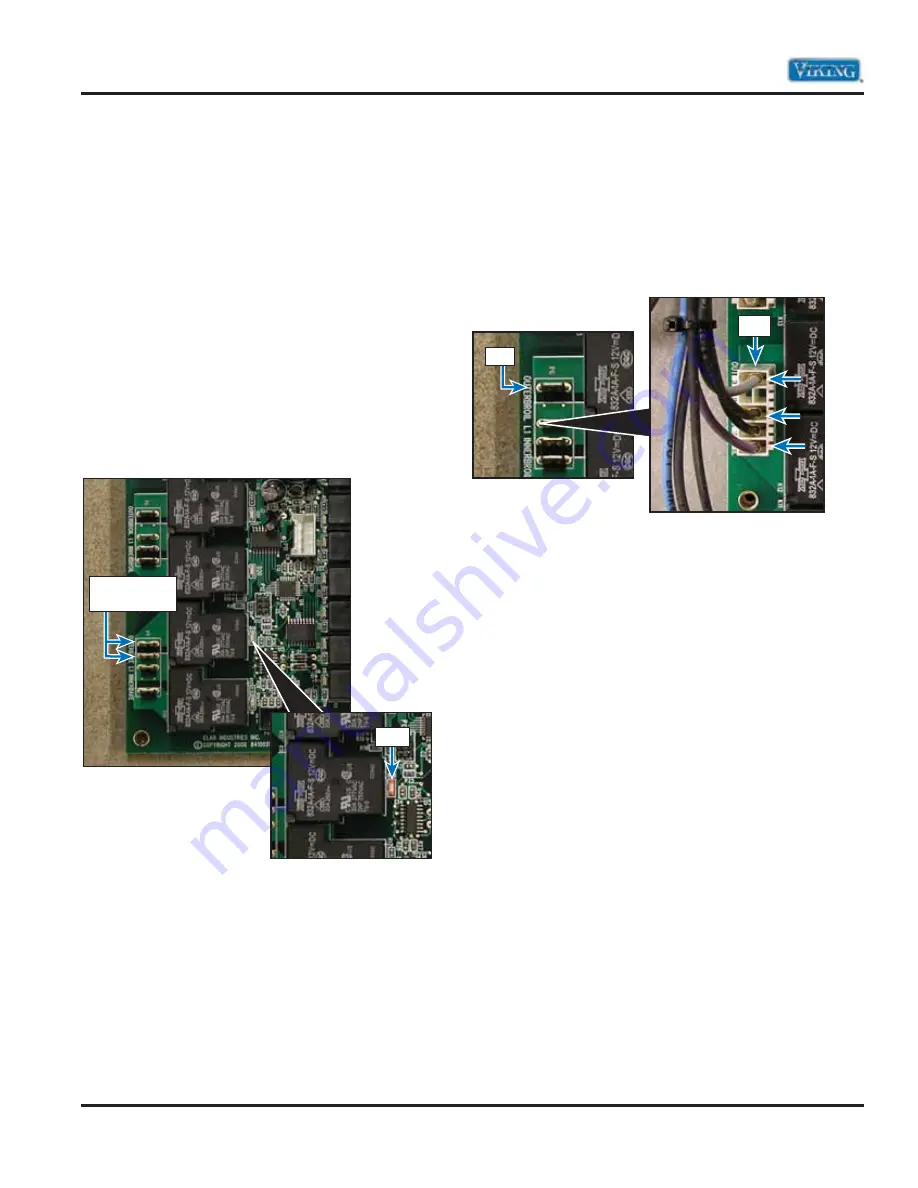

Relay Board Diagnosis

Bake Relay

The VESO and VDSO series oven use one

concealed bake element in the cavity floor. It is

connected on the relay board to the outer bake

connection (inner bake is not used).

When the bake relay contact is energized (red LED

D19 at base of relay is illuminated red), check for

240 VAC between the yellow wire at the line break

relay and the blue wire on P9. If 0 VAC is measured,

disconnect power and remove the P9 Molex plug.

Reconnect power and using an Ohmmeter, check

for continuity between the relay contacts. When the

relay is energized; if infinite ohms (

1

) are measured,

this indicates a bad relay and replacement of the

relay board is necessary. If 0 ohms are measured,

the relay contact is closing.

Broil Element

Locate the P6 connector and the line break relay on

the relay board. The P6 connector will have a Molex

plug containing a violet, black, and gray wire. The

violet wire goes to the inner broil element, the

black wire is L1 input from main power supply, and

the gray wire goes to the outer broil element.

With the power off and Molex connector removed

from the P6 relay board connection, use an

Ohmmeter to measure resistance between the

violet wire in the Molex plug and the yellow

wire at the line break relay. This will measure the

resistance of the inner broil element and should

be approximately 24

1

. Likewise, the outer broil

element can be measured by reading resistance

between the gray wire in the Molex plug and the

yellow wire at the line break relay. A resistance

of approximately 45

1

should be found. If either

element fails to read resistance, remove the

element to repair or replace as necessary

(see Broil Element Disassembly, page 57).

Place meter

leads here

P-6

P-6

LED