WARNING

To avoid electrical shock which can cause severe personal injury or death, disconnect

power to refrigerator using power switch before servicing. Wires removed during

disassembly must be replaced on proper terminals to insure correct earth ground and

polarization. After servicing, reconnect power using power switch.

Evacuation and Charging

CAUTION: To avoid risk of fire, sealed

refrigeration system must be air free. To

reduce risk of air contamination, follow

evacuation procedures exactly.

NOTE:

Before opening any refrigeration

system, EPA regulations require refrigerant in

system to be captured for safe disposal.

Proper evacuation of sealed refrigeration system

is an important service procedure. Usable life

and operational efficiency greatly depends upon

low completely air, moisture and other non-

condensables are evacuated from sealed system.

Equipment Setup For Evacuation and Charging

5. After compound gauge (low side) drops

NOTE:

produce

e evacuating system until

7.

to

•

minutes, micron level stabilizes at

•

rises above 400 microns

•

s rapidly and does

ep 1.

Air in sealed system causes high condensing

temperature and pressure, resulting in increased

power requirements and reduced performance.

to approximately 29 inches gauge, open

valve “C” to vacuum thermocouple

gauge and take micron reading.

A high vacuum pump can only

Moisture in sealed system chemically reacts

with refrigerant and oil to form corrosive

hydrofluoric and hydrochloric acids. These

acids attack motor windings and parts, causing

premature breakdown.

a good vacuum if oil in pump is not

contaminated.

6. Continu

vacuum gauge registers 200 microns.

At 200 microns, close valve “A”

Before opening system, evaporator coil must be

at ambient temperature to minimize moisture

vacuum pump and allow micron reading

in system to balance. Micron lever will

rise.

If in 2

infiltration into system.

Evacuation:

To evacuate sealed refrigeration

system:

400 microns or below, system is ready

to be charges.

If micron level

1. Connect vacuum pump, vacuum tight

manifold set with high vacuum hoses,

thermocouple vacuum gauge and

charging cylinder as shown in

illustration. Evacuation should be done

and stabilizes, open valve “A” and

continue evacuating.

If micron reading rise

not stabilize, a leak still exists in system.

Close valve “A” to vacuum pump an

through I.D. opening of tubes not

through line piercing valve.

valve “C” to vacuum gauge. Invert

charging cylinder and open charging

cylinder valve “F” to add partial charge

for leak checking. With leak detector,

check manifold connections and system

for leaks. after locating leak, capture

refrigerant, repair leak, and begin at st

2. Connect low side line to compressor

process tube.

3. Connect high side line to drier/process

tube.

4. Evacuate both simultaneously. With

valve “C” and “F” closed, open all other

valves and start vacuum pump.

17

Summary of Contents for DFSB483D

Page 1: ...VCSB483D DFSB483D DDSB483D COVER F90597...

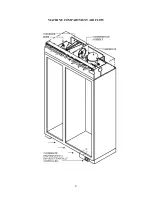

Page 4: ...VCSB483D with ICE and WATER 4...

Page 5: ...CABINET AIR FLOW 5...

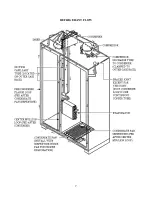

Page 6: ...MACHINE COMPARTMENT AIR FLOW 6...

Page 7: ...REFRIGERANT FLOW 7...

Page 8: ...WATER FLOW 8...

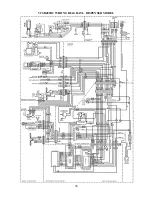

Page 27: ...VCSB483 WIRING DIAGRAM 27 27...

Page 28: ...VCSB483D WIRING DIAGRAM DISPENSER MODEL 28...

Page 38: ...CONTROL BOARD OPERATION 38...

Page 39: ...TROUBLESHOOTING 39...

Page 40: ...TROUBLESHOOTING con t 40...

Page 45: ...45...