Summary of Contents for DFSB483D

Page 1: ...VCSB483D DFSB483D DDSB483D COVER F90597...

Page 4: ...VCSB483D with ICE and WATER 4...

Page 5: ...CABINET AIR FLOW 5...

Page 6: ...MACHINE COMPARTMENT AIR FLOW 6...

Page 7: ...REFRIGERANT FLOW 7...

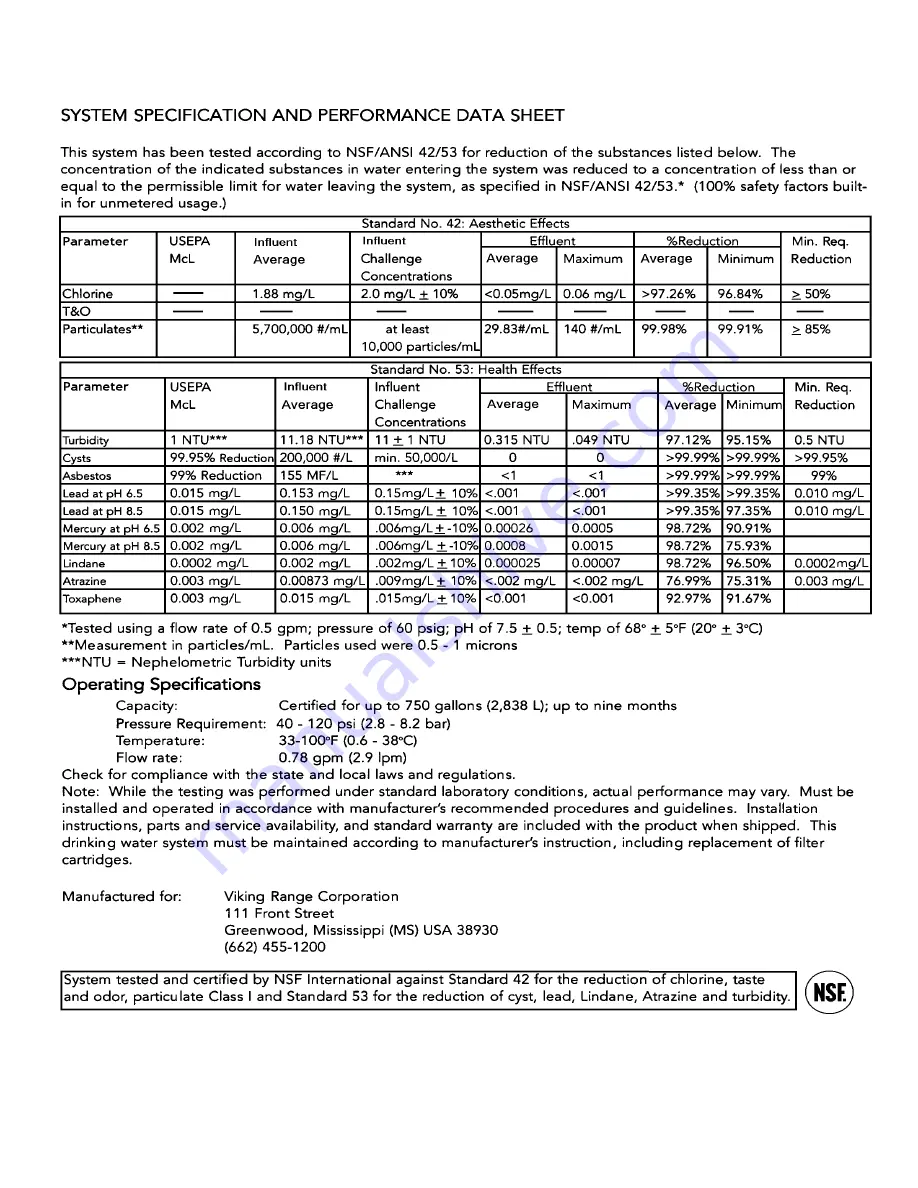

Page 8: ...WATER FLOW 8...

Page 27: ...VCSB483 WIRING DIAGRAM 27 27...

Page 28: ...VCSB483D WIRING DIAGRAM DISPENSER MODEL 28...

Page 38: ...CONTROL BOARD OPERATION 38...

Page 39: ...TROUBLESHOOTING 39...

Page 40: ...TROUBLESHOOTING con t 40...

Page 45: ...45...