WATER LINE CONNECTIONS

Avoid routing tubing behind ovens and other

cooking appliances. Avoid kinking,

smashing the tubing as this can cause leaks

or diminished flow. The tubing can be cut

to the proper length, but leave enough slack

coiled below your refrigerator to allow it to

be rolled out for cleaning and service.

Make sure that all tubing ends are cut

square and not at an angle.

To Avoid Property Damage, Observe the

following:

•

Confirm inlet water pressure to water

valve is alt least 35 pounds per

square inch(PSIG).

•

Confirm water pressure to water

valve does not exceed 120 PSIG.

•

Maximum operating temperature is

125

°

F.

•

Check carefully for water leaks

immediately after installation and 24

hours after installation.

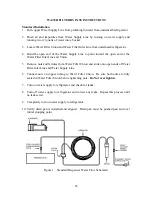

TO ROUGH IN WATER LINE

1. Turn OFF main water supply. Turn

ON nearest faucet long enough to

clear line of water.

2.

Vertical cold water line:

Use

grounded electric drill or hand drill

to drill 3/16” (4.5cm) hole in an

easily accessible location in water

ling.

Horizontal cold water line:

Use

grounded electric drill to drill 3/16”

(4.5cm) hole in the TOP of the water

line. This will keep sediment from

collecting in valve.

3. Position washer over hole in water

line. Turn saddle valve handle

clockwise to expose piercing lance a

maximum of 3/16” (4.5cm). Align

piercing lance over hole in water

line. Place both halves of saddle

valve bracket against water line.

Turn saddle valve handle clockwise

until piercing lance enters hole in

waterline and is firmly seated. The

saddle valve is now in the closed

position. Tighten packing nut.

Evenly and firmly tighten bracket

screws so washer will

make a water-tight

connection.

Do not

over tighten screws

:

copper tubing could

be crushed.

4. Check that both ends of

copper tubing are cut

square. Slide

compression nut and sleeve onto

copper tubing. Insert end of copper

tubing completely into valve outlet.

Tighten compression nut to outlet

with adjustable wrench.

Do not

over tighten.

5. Turn on main water supply. Check

for leaks. Turn saddle valve handle

counterclockwise to shut off water to

copper tubing.

6. Route copper tubing to refrigerator

area.

7. Leave an additional length of copper

tubing coil fo facilitate moving the

refrigerator out of enclosure for

cleaning or service.

•

Do not use plastic water lines between

refrigerator and supply. Plastic water

lines can fail due to fatigue over time

and cause extensive damage to

product and the home.

•

Use only ¼” (1.6cm) copper tubing for

water line.

•

Do not connect to reverse osmosis

water system.

46

Summary of Contents for DFSB483D

Page 1: ...VCSB483D DFSB483D DDSB483D COVER F90597...

Page 4: ...VCSB483D with ICE and WATER 4...

Page 5: ...CABINET AIR FLOW 5...

Page 6: ...MACHINE COMPARTMENT AIR FLOW 6...

Page 7: ...REFRIGERANT FLOW 7...

Page 8: ...WATER FLOW 8...

Page 27: ...VCSB483 WIRING DIAGRAM 27 27...

Page 28: ...VCSB483D WIRING DIAGRAM DISPENSER MODEL 28...

Page 38: ...CONTROL BOARD OPERATION 38...

Page 39: ...TROUBLESHOOTING 39...

Page 40: ...TROUBLESHOOTING con t 40...

Page 45: ...45...