1. Pull copper line from

plumbing forward

from underneath

refrigerator (see fig.

A.) Flush air and

impurities from water

line be turning on

water supply and running two (2) quarts

of water into a bucket.

2. Connect brass fitting (located in

literature packet) to plastic line with nut

and sleeve.

3. Turn on water supply to refrigerator and

check for leaks.

4. Turn off water supply to refrigerator and

correct any leaks. Repeat this process

until no leaks exist.

5. Completely turn on water supply to

refrigerator.

6. Verify drain pan is installed and aligned

properly. Drain pan must be pushed

past and over initial stopping point.

ICE MAKER

Operation

Thermostat closes when temperature reaches

17

°

±

3

°

F (-8.3

°

±

1.5

°

C). Current flows

through thermostat to motor. See “Ice

Maker Wiring Diagram”. Motor is linked

with drive gear. From module, there are

copper contacts that ride on copper strips on

backside of drive gear. As the drive gear

rotates, contacts will make or break a circuit

(tract) to the copper strips to operate ice

maker.

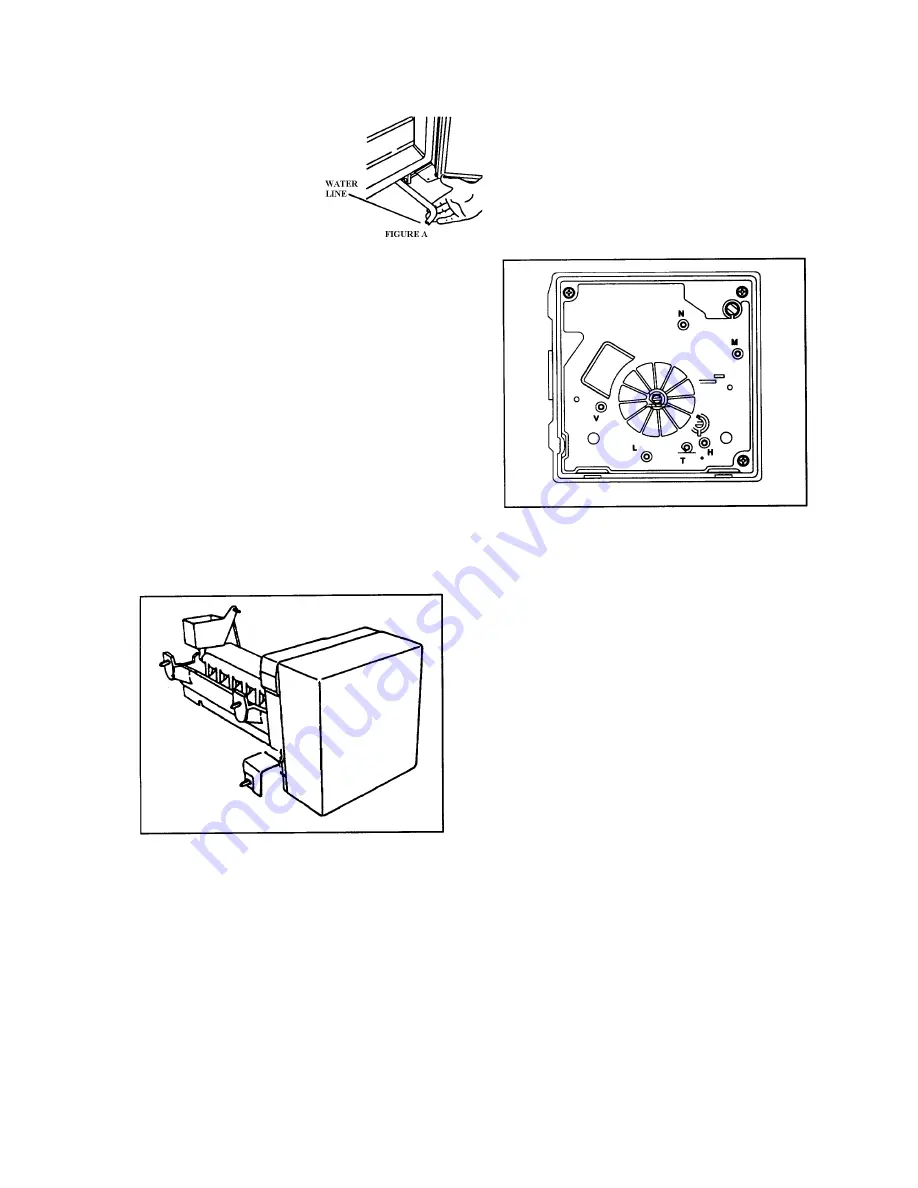

Test points are identified on module:

N = Neutral side of line

M = Motor connection

H = Heater connection

T = Thermostat connection

L = L1 side of line

V = Water valve connection

Specifications

Mold heater: 185 watts, 264 ohms

Thermostat: Close 17

±

3

°

F (-8

±

1

°

C)

(Bimetal) Opens 32

±

3

°

F (0

±

1

°

C)

Water fill: 140 cc, 7.5 sec.

Motor cycle Stamped in circuit.

Plug in connectors

One revolution of blades takes

3 minutes plug stall time on ice

Testing Procedures

Verify ice maker has power, shut off arm is

down, and freezer is cold enough to close

bimetal thermostat.

•

Test point L and N will verify 120

volts to ice maker module.

•

Test point T and H will verify bimetal

thermostat is open or closed.

•

Verify test probes go into test points

½ inch (1.25 cm).

1. Short T and H with a shunt

(insulated 14 gauge wire with ends

stripped back 5/8 inch (1.6 cm) to

run motor. If motor runs. Replace

bimetal thermostat. If motor does

not run, replace module.

47

Summary of Contents for DFSB483D

Page 1: ...VCSB483D DFSB483D DDSB483D COVER F90597...

Page 4: ...VCSB483D with ICE and WATER 4...

Page 5: ...CABINET AIR FLOW 5...

Page 6: ...MACHINE COMPARTMENT AIR FLOW 6...

Page 7: ...REFRIGERANT FLOW 7...

Page 8: ...WATER FLOW 8...

Page 27: ...VCSB483 WIRING DIAGRAM 27 27...

Page 28: ...VCSB483D WIRING DIAGRAM DISPENSER MODEL 28...

Page 38: ...CONTROL BOARD OPERATION 38...

Page 39: ...TROUBLESHOOTING 39...

Page 40: ...TROUBLESHOOTING con t 40...

Page 45: ...45...