Diagnostic Information

10

SMR-0003

© Viking Range Corporation

Interior Light and Switch

For Wine Cellars/Beverage Centers:

The light will automatically turn on when the door is

opened and off when the door is closed. To engage the

display light feature, press the “LIGHT” button on the

display panel. The light will come on and stay on, even

with the door closed, until the “LIGHT” button is pressed

again.

For Refrigerated Drawers:

The light switch will automatically turn on the light when

the drawer(s) is opened and off when the drawer(s) is

closed. There are two light switches in each drawer unit:

one on the top and one on the bottom. They are both

located on the inside left hand of the drawers. In addition

to turning the light on and off, the light switches also turn

the display panel and interior fan(s) on and off.

Sabbath Mode

The unit is equipped with a Sabbath Mode of operation.

When Sabbath Mode is enabled, the displays, audible

alarms, lights, and all options are disabled. The user

interface buttons remain enabled with audible key tones

disabled.

Enabling Sabbath Mode:

Press and hold the “SET” button while pressing the “

°F/C” button four (4) times within seven (7) seconds. The

display will flash “SA” seven (7) times and then the unit

will enter Sabbath Mode.

Disabling Sabbath Mode:

Press and hold the “SET” button while pressing the “

°F/C” button four (4) times within seven (7) seconds.

Sabbath Mode automatically disables after 72 hours.

1.

A power outage will not disable Sabbath Mode.

2.

Disabling can only be accomplished by the

automatic time-out or by the user.

The display returns to operation prior to Sabbath

3.

Mode activation.

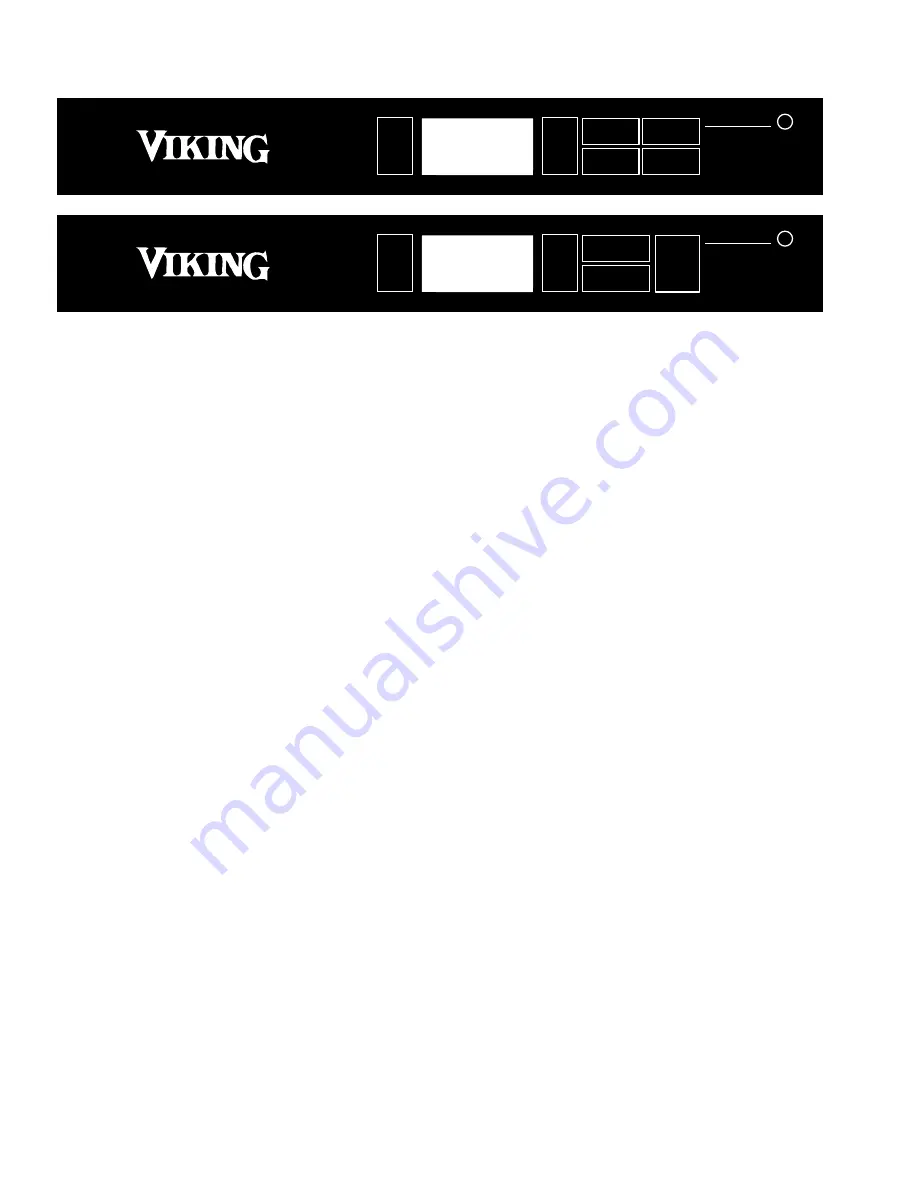

User Interface Panel and Tru Protect

™

System

OFF

PRESS AND HOLD

TruProtect System

POWER FAILURE - Flashing Amber

HIGH/LOW TEMP - Red

ALARMS OFF - Steady Amber

PRESS ON/OFF - Reset

SET

WARMER

COLDER

F/C

LIGHT

OFF

PRESS AND HOLD

TruProtect System

POWER FAILURE - Flashing Amber

HIGH/LOW TEMP - Red

ALARMS OFF - Steady Amber

PRESS ON/OFF - Reset

SET

WARMER

COLDER

F/C

Overview

Viking’s Tru Protect™ system informs the user if the

unit is not functioning properly through both visual and

audible alerts. The LED display panel displays a steady

green light when the Tru Protect™ system is enabled.

Starting the Unit

To start the unit, push and hold for five (5) seconds the

“ON/OFF” button located on the display panel. Upon

turning the unit on, the display will read the actual

temperature inside of the unit. If the interior temperature

is greater than 99 degrees F, the display will flash 99

until the temperature drops to 99 degrees F.

Setting the Temperature Mode

The unit can display either Fahrenheit (F) or Celsius (C).

To do so, press the “ °F/C” button on the display panel.

Adjusting the Temperature Control

The temperature control is fully adjustable from the low

40s to the mid 60s in the wine cellars and beverage

centers. The set point out of the factory is approximately

55 degrees F. The temperature control is adjustable from

the low 30s to the high 40s in the refrigerated drawers.

The set point out of the factory is approximately 38

degrees F. The range, whether it be for wine cellars

and beverage centers or refrigerated drawers, allows

flexibility of temperature preferences and provides the

ideal wine aging or food storing temperatures. The

temperature can be lowered or raised by first pressing

the “SET” button on the display panel. A “SET” icon

will be displayed. This icon will turn off 10 seconds

after completing the adjustments. Pressing either the

“WARMER” or “COLDER” buttons will raise or lower the

set temperature by one (1) degree F or C (depending

on the setting). NOTE: As with any refrigeration product,

there is a slight temperature variance at different

locations within the cabinet.