Diagnostic Information

12

SMR-0003

© Viking Range Corporation

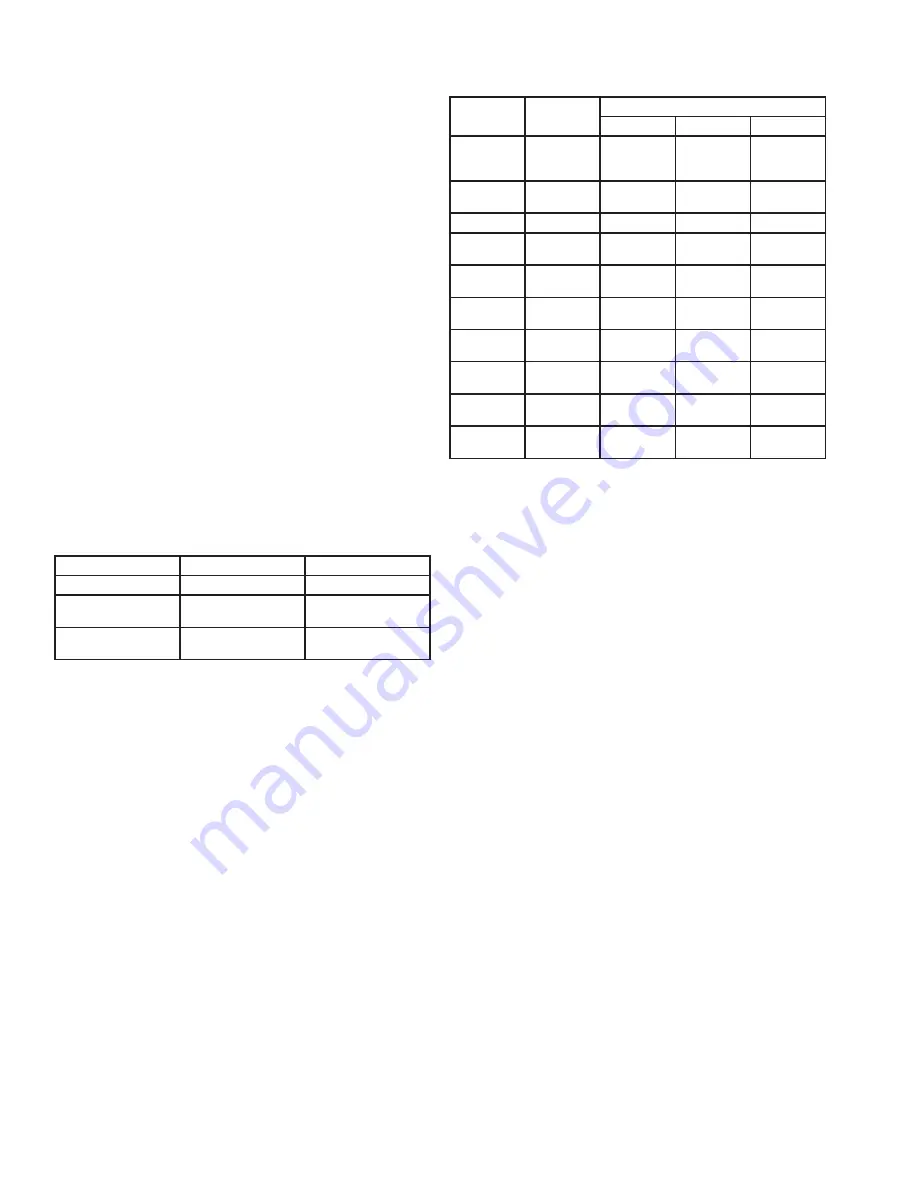

Available Component Tests

Test #

Component

Description

Available Status Indicators

OK

Off/Open

On/Shorted

0

Temp

Sensor A -

Evaporator

0-

00

01

1

Temp Sensor

B - Display

1-

10

11

2

Compressor

n/a

20

21

3

Interior/Ice

Maker Fan

n/a

30

31

4

Reverse Gas

Solenoid

n/a

40

41

5

Condenser

Fan

n/a

50

51

6

Mullion

Heater

n/a

60

61

7

Door A

Sense

n/a

70

71

8

Door B

Sense

n/a

80

81

9

Door C

Sense

n/a

90

91

Note:

Must use magnet to change state of door C sense

Disabling Service Mode:

To exit service mode, press and hold the “WARMER”

button while pressing the ”COLDER” button four (4)

times within five (5) seconds.

Service Mode will automatically disable after five (5)

•

minutes of no keypad entry.

Ordering Parts

The following information will need to be given when

inquiring about service parts:

Model and serial number located on the serial

•

nameplate (see Introduction, Serial Nameplate)

Color of the model

•

Metal or plastic grille

•

Type of door

•

To order parts, call or write:

Viking Range Corporation

Customer Service

111 Front Street

Greenwood, Mississippi 38930 USA

662.455.1200

For product information, call 1.888.VIKNG1 (845.4641)

or visit the Viking Web Site at vikingrange.com

Service Diagnostics Mode

Service Diagnostics Mode allows you to identify the

firmware and software versions, test status of “model

specific” system components and sensors, and change

state of components where applicable (i.e. - compressor

on/off, etc...).

Enabling Service Mode:

To enable Service Mode, press and hold the “WARMER”

button while pressing the “COLDER” button four times

within five seconds.

You cannot enable Service Mode while in Set Mode.

•

All system functions will remain in their current state

•

while in Service Mode.

Alarms are disabled during Service Mode and reset

•

after exiting Service Mode.

Service Mode will automatically disable after five (5)

•

minutes of no keypad entry.

After entering Service Mode, the first number that you

will see indicates the software model number for the

particular unit you are servicing. For example, if you are

servicing a 24 inch wine cellar (DFUW, DUWC, VUWC),

the first number you will see is 11. See chart below for

corresponding model and software reference.

Software Model Number

Model

Description

Software Model Number

DFUW, DUWC, VUWC

24 inch Wine Cellar

11

DFUR, DUAR, VUAR

24 inch Beverage

Center

21

DFRD, DURD, VURD

24 inch Refrigerated

Drawers

16

The second number you will see indicates the software

version release. For example, if you see 44 on the

display panel it indicates software version 4.4.

Diagnostics:

While in Service Mode, press the “SET” button to step

through Tests 0-9. The first digit of the display will show

the test number. The second digit indicates the current

state of each component under test and is displayed as

“1” being ON, CLOSED, or SHORTED and “0” being

OFF or OPEN. Tests 0 and 1 reveal an open or shorted

condition detected at the sensor inputs. Tests 2 through

6 allow you to turn loads ON with the “WARMER” button

and OFF with the “COLDER” button. Tests 7 through 9

verify state change of the door switches and/or magnetic

reed sensor. The component tests available are

described in Available Component Tests chart.