Disassembly

20

SMR-0003

© Viking Range Corporation

Charge the unit.

8.

Reinstall back panel and lower shroud to complete

9.

installation.

Compressor

Removing the compressor

Disconnect power to the unit.

1.

Remove the back panel and lower shroud.

2.

Remove the screws that hold the baseplate to the

3.

chair frame of the unit and slide out the mechanical

baseplate.

Install sealed system access valve(s) and recover

4.

refrigerant. After recovering, be sure to cap off the

access valve(s) to prevent contamination of the

system.

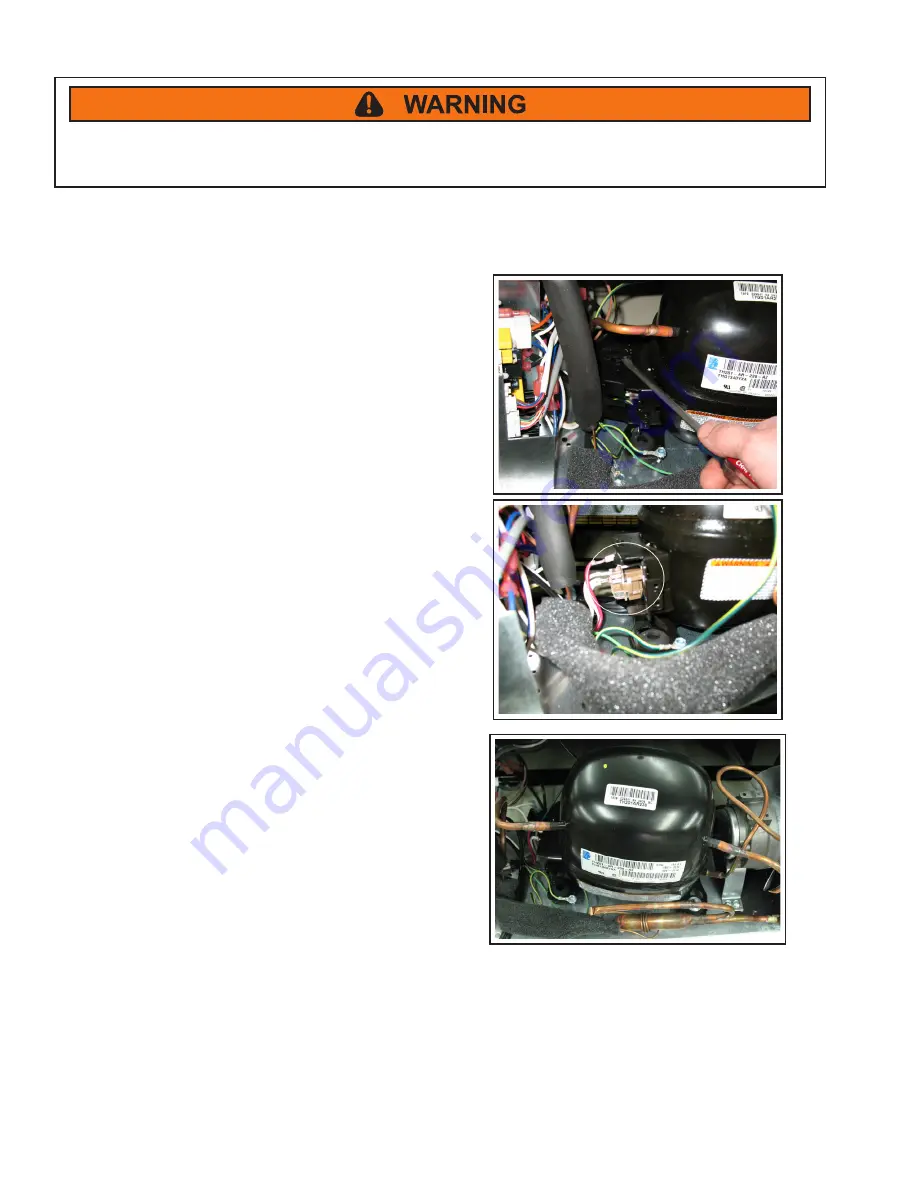

Remove the cap from the rear of the compressor to

5.

expose the starter and overload.

Disconnect the PTC starter and overload from the

6.

compressor by pulling off. Disconnect the wires from

the starter and overload.

Un-braze and remove capillary tube from drier

7.

assembly.

Un-braze and remove suction line at compressor.

8.

Un-braze high side line from the compressor going

9.

to the condenser.

Remove compressor by removing the three lock

10.

nuts on the mounting plate of the compressor. Lift

the compressor off of the carriage bolts.

Installing the Compressor:

Install the four rubber grommets in the bottom of the

1.

new compressor and install the three sleeves where

the carriage bolts will be located. Mount the new

compressor and install the three washers and lock

nuts and tighten to 45 in-lbs. DO NOT REMOVE

THE RUBBER PLUGS AT THE TUBE STUBS ON

THE COMPRESSOR AT THIS TIME.

Install and braze new drier assembly to condenser.

2.

Then install and braze capillary tube to drier.

Remove the plug for the high side line to condenser.

Install and braze the line to the compressor.

Remove the plug for the process tube on the

3.

compressor. Install and braze process tube. Be sure

to cap off end to prevent any contamination.

Remove the plug for the suction line on the

4.

compressor. Install and braze the suction line from

the evaporator. BE SURE TO ALSO REINSTALL

THE SUCTION LINE AND TUBING HARNESS

INSULATION TUBES.

Reinstall the PTC starter and overload and wire

5.

according to the wiring diagram.

Reinstall the compressor cap.

6.

Reinstall the screws that secure the baseplate to the

7.

chair frame of the unit. Be sure to fasten down the

ground wire to the baseplate.

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.