20

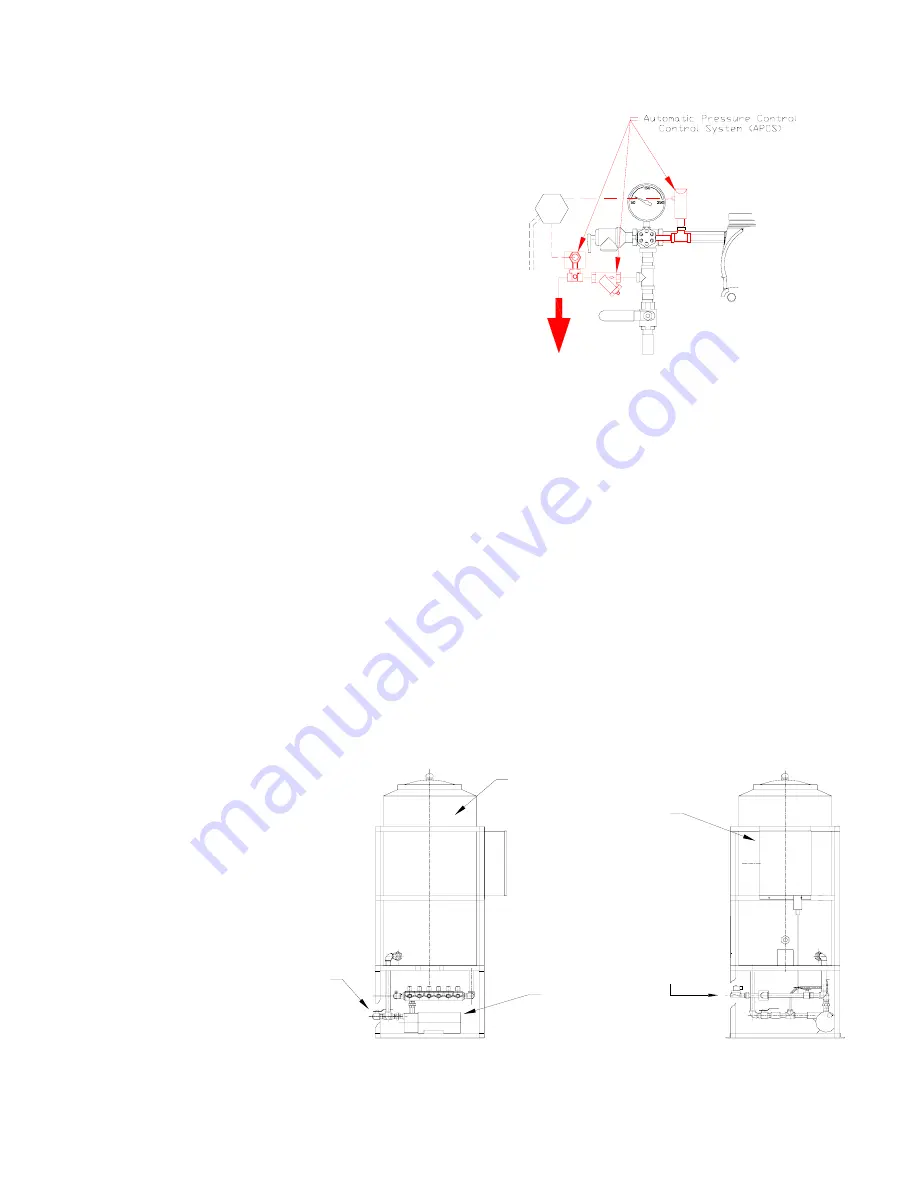

For freezers or coolers that

fluctuate in temperature, an

automatic pressure control

system is required that utilizes

a special DIGITAL pressure

switch and solenoid valve that

allows antifreeze to be relieved

back into the CS-1 or reclaim

tank. Calculation of volume

fluctuation of the largest system

where multiple systems are

installed must be made in order

to make sure the tank volume

of antifreeze supply is large

enough to contain the volume differential. The APCS set point shall be at

least 5 PSI (34,5 kPa) greater than the maximum static or residual

supervisory pressure of the system. The PRV will be utilized as a safety

backup to the pressure control system in case of power loss and non-

presence of backup power system to the freezer temperature control

system.

If the pressure should increase due to warm-up above the rated static

pressure of the system, the pressure relief valve or automatic control

system will bleed off antifreeze solution and maintain the maximum

pressure of 175 PSI (1 207 kPa) or below at the sprinkler. It is

recommended to fill the system with antifreeze after the freezer is at the

sustained set temperature. Or, cool the antifreeze solution in the freezer

area and then add it to the system. This will allow the piping system to

establish a normal ambient temperature when filling the system with

antifreeze. Slight warming will occur during the fill process. Another option

is to fill the system while warm. Monitor tank level and add more solution

as needed as temperature cools.

5.1.8 CS-1 Pump

ISOLATION VALVE

SYSTEM(S)

CONNECTION(S)

PUMP

65 OR 160

CONTROL

PANEL

LIQUID SUPPLY

GALLON TANK

Summary of Contents for ESFR

Page 5: ...5 Figure 1 Straight Through Configuration...

Page 6: ...6 Figure 2 Angle Style Configuration...

Page 10: ...10...

Page 35: ...35...