23

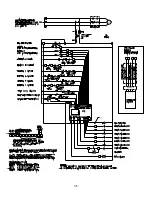

The system must include a supervised system control valve upstream of

the deluge valve and a supervised system isolation valve downstream of

the isolation check valve. The downstream system isolation valve is

required to facilitate maintenance of the system and isolation of antifreeze

solution during maintenance and testing. A pressure relief valve on the

antifreeze side of the primary check valve shall be pre-set to protect the

sprinklers at 175 PSI (1 207 kPa) and piped to drain. This will handle

over-pressurization due to thermal differentials in the area of the

antifreeze piping and system operation. Consideration of location height

of PRV relative to the sprinklers must be taken into account. Calculate the

differential height and specific gravity of antifreeze at the operating

temperature of the freezer and size the PRV relief pressure accordingly.

The alarm line of the deluge valve shall be attached to an alarm pressure

switch (and mechanical water motor alarm, if required) that activates an

alarm due to activation of the system. An additional supervisory pressure

switch on the primary check valve system side is required in order to

provide a low pressure alarm in the case of antifreeze pressure loss due

to sprinkler operation without a fire condition. In this case the antifreeze

supply must be manually shut off to the low-pressure riser. There is an

isolation valve located on the antifreeze inlet line of the riser primary

check valve.

5.1.11 Alarm Test Connection

An alarm test connection is provided on the

deluge valve trim. When testing the alarm, the

downstream isolation valve and antifreeze

isolation valve must be shut before opening the

test valve.

This is a precaution in case the deluge valve

would inadvertently operate due to problems in

the trim components and cause water to enter the

system causing possible contamination of

antifreeze. After testing of the alarm, restore the

control valves to their normal operating position

and open the antifreeze supply valve.

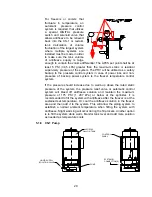

5.1.12 Flow Test Valve (also known as Main Drain Valve)

Annual flow tests are required for

every sprinkler system. When

performing annual water flow tests

for the Pre-Primed Single Interlocked

Preaction Cold Storage System, you

will utilize the main drain of the

isolation check valve. This will allow

the primary check valve clapper to

open also. First, close the supervised

system isolation valve downstream of

the isolation check valve. Close the

Summary of Contents for ESFR

Page 5: ...5 Figure 1 Straight Through Configuration...

Page 6: ...6 Figure 2 Angle Style Configuration...

Page 10: ...10...

Page 35: ...35...