30

supply. The tank and pump system automatically maintains the supervisory

solution pressure in the piping above the check valves, until the detection system

is activated. When the detection system is activated, the deluge valve is operated

from the system releasing control panel. In the event of a fire condition, the

detection system operates the deluge valve and pressurizes the system with the

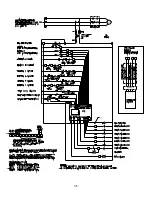

design discharge water pressure. The system pressure control switch is wired

through the alarm pressure switch located on the deluge valve. In a fire condition,

the CS-1 antifreeze pump unit keeps the supply solenoid valve closed that is

supplying the operated riser system. In a situation where a sprinkler opens,

breaks off, or pipe ruptures, causing a low pressure supervisory condition without

a fire condition, the low pressure supervisory switch located on the primary check

valve will provide an alarm. In this case, the antifreeze supply valve on the

alarmed riser must be manually shut off. The pump uses antifreeze in the storage

tank to maintain system pressure and make up for minor system leaks.

The system is designed to accept up to 50% propylene glycol and water premix

solution. It is recommended that Viking certified premix be used. Do not mix

different antifreeze solutions within the system.

WARNING:

Motors, electrical equipment, and controls can cause electrical arcs

that will ignite a flammable gas or vapor. Never operate or repair in or near a

flammable gas or vapor. Never store flammable liquids or gases near the unit.

SAFETY:

This equipment is designed to be safe in the use for which it was

planned, provided it is installed, started up, operated, and maintained in

accordance with the instructions in this manual. Therefore, all personnel who

install, use, or maintain the equipment must understand this manual. The unit

contains electrical components that operate at line voltage and moving parts.

Before working on the unit, isolate and lock it out from the electrical supply. All

maintenance operations must be performed by qualified persons who have

knowledge in the necessary precautions.

NOTE:

The Viking ESFR Cold Storage System shall be designed by qualified fire

protection technicians, in conjunction with requirements of the Authorities Having

Jurisdiction. These systems are designed to meet the UL Listing requirements

described in Viking technical data for ESFR K25.2 Sprinkler VK510 for use with

propylene glycol/water solution, and the standards of NFPA 13 or other

organizations, and also with the provisions of governmental codes, ordinances,

and standards where applicable.

7.2 Operating

Principle

The tank and pump system maintains antifreeze in sprinkler system piping at

desired supervisory pressure 50 PSI (344 kpa) minimum recommended

pressure. A pressure switch on the unit senses the CS-1’s discharge manifold

pressure and turns the pump on as the unit pressure drops to a preset pressure,

and then stops the pump as unit pressure rises to a higher preset pressure. A

level switch mounted in the storage tank opens when the liquid level is low.

When the level switch opens, pump operation is inhibited and a set of dry

contacts changes state for the user’s supervisory system. Terminals 21, 22, and

23 are for connection of low alarm devices. Also, the primary check valve

Summary of Contents for ESFR

Page 5: ...5 Figure 1 Straight Through Configuration...

Page 6: ...6 Figure 2 Angle Style Configuration...

Page 10: ...10...

Page 35: ...35...