37

Size piping between the CS-1 and the system to minimize pressure drop.

Too small of a line size restricts pump flow, lowering capacity when filling

the system. Lower capacity while filling the system requires longer fill

times. The sprinkler system must contain air vent/bleed valves at all local

high points. These are used to let air out of the system while filling with

antifreeze. Consult the system instructions for specifics.

Individual check valves and isolation valves are required for each system.

This allows system maintenance without disturbing other systems the CS-

1 is connected to. Piping and/or hoses from the antifreeze supply

containers to the unit should be sloped downhill slightly to provide positive

head on the pump suction connection. These lines should be as large as

possible and as short as possible to provide unrestricted flow to the pump

while filling. A separate shut-off valve in the supply line is required.

Unit piping is copper, brass and bronze. An aluminum manifold is

included for mounting multiple system solenoids. Use dielectric unions to

isolate copper piping from iron piping, if used, to reduce the possibility of

electrolytic action on pipes and other components.

All pipes should be de-burred and threaded to a proper depth and length

before installation. Threads should be inspected for cleanliness and depth

of cut. Good quality pipe compound should be used to ensure a good,

leak tight fit of piping components.

NOTE: Pipe must be supported separately from the CS-1. At no time

should the CS-1 support the weight or load of the pipe. Acceptable pipe

mounting devices would be unistrut supports anchored to walls, hangers

suspended from ceilings, or pedestals mounted from the floor. Be sure all

pipe installation conforms to all building & fire codes.

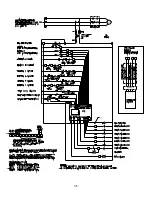

7.5 Electrical

Connections

SERIOUS PERSONAL INJURY AND DAMAGE TO THE CS-1 COULD

OCCUR

IF IT IS CONNECTED TO A POWER SOURCE OTHER THAN THE VOLTAGE

LISTED ON THE DATA TAG. THE MANUFACTURER IS NOT LIABLE FOR

DAMAGE DUE TO IMPROPER WIRING, PROTECTION, OR ELECTRICAL

SERVICE INSTALLATION.

WHEN INSTALLING ELECTRICAL SERVICE TO THIS MACHINE, COMPLY

WITH THE NATIONAL ELECTRIC CODE AS WELL AS STATE AND LOCAL

BUILDING CODES.

FAILURE TO INSTALL THE PROPER ELECTRICAL PROTECTION CAN

RESULT IN PERSONAL INJURY, FIRE, EQUIPMENT DAMAGE, OR DEATH.

THE MFR IS NOT RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY

LACK OF OR IMPROPERLY INSTALLED ELECTRICAL PROTECTION.

Electrical connection to the unit is made in the control enclosure. Connect

appropriate supply power to the terminals provided. The supply wire must be of

adequate size and no other equipment should be connected to the same circuit.

Summary of Contents for ESFR

Page 5: ...5 Figure 1 Straight Through Configuration...

Page 6: ...6 Figure 2 Angle Style Configuration...

Page 10: ...10...

Page 35: ...35...