9

8

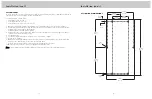

INSTALLATION OVERVIEW

The ice machine must:

• Be connected to cold, potable water.

• Be connected to a drain.

• Be connected to the proper power supply.

• Be able circulate air through the vents at the front.

Note: DO NOT build in so that the door is recessed. Door is meant to be flush with surronding cabinetry, but

not recessed.

INSTALLATION PARTS

The following installation parts are supplied with the ice machine:

2

-Hinge covers

2

-Door stop pins

2

-Hinge side covers

10

-#8 sheet metal screws

2

-Hole plugs

2

-8-32 Machine screws

2

-Hinge opening covers

4

-Leveling leg caps

1

-Upper door bracket (LH)

2

-Black kickplate screws

1

-Lower door bracket (LH)

1

-Access panel button cover

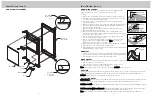

ACCESSORY DOOR PANEL

The ice machine is supplied without a finished door panel. Accessory door panels are offered or a custom panel may

be used.

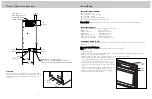

Accessory Door Panel Attachment

Note: If door swing is to be changed, it must be done before panel is attached.

To attach a door panel:

The panel will be held on by 6 screws (supplied with door panel) and 2 machine screws (supplied with ice machine).

1. Remove the gasket and retain for later use.

2. If the door panel is stainless steel, remove any plastic covering the stainless steel panel.

3. Place the panel onto the outside of the door, and secure it

to the door using two machine screws, located at the left

center and right center ( behind door gasket).

4. Fasten the panel to the door using the 6 screws (supplied

with door panel). In the hinge area, use the outermost screw

holes.

5. Place the covers over the hinge areas, and secure each cover

to the door using a screw (supplied with door panel).

6. Insert hole plug over screw installed in step 5 (supplied).

7. Return the gasket to its original position.

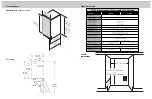

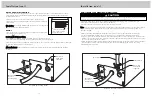

Air

intake

Warm

air out

2-3/4”

(7.0 cm)

5-1/8”

(13.0 cm)

1/4” (0.6 cm)

O.D. Copper Water

Inlet Compression

Fitting Provided

2-1/2”

(6.4 cm)

7-1/2”

(19.1 cm)

11-5/8”

(29.5 cm)

115V

Power Cord

3-1/4”

(8.3 cm)

Drain Access - Flexible Tubing

3/8” (.95 cm) I.D. Pump Model (included)

5/8” (1.6 cm) I.D. Gravity Model (not included)

Drain / Electrical Location

Installation

Hole

plug

Cover

Gasket

AIR FLOW

The machine takes in room temperature air at the lower right

front and forces warm air out the lower left front. Restricting the

airflow will adversely affect the ability of the ice machine to

make ice.

Summary of Contents for FGNI515

Page 10: ...19 18 ...