Technical Information 15.01

- Page 2 -

Overview:

1. General information

2. Appliance overview

3. Cutting height adjustment

4. Engine oil and fuel

5. Maintenance

6. Troubleshooting

7. Technical specifications

8. Repair times

9. Spare parts list

1.

General information

Always read the instruction manual before operating

for the first time. National legislation and the safety

instructions in the instruction manual must be

observed for repairs or maintenance, particularly

when operating the appliance for the first time

(test run).

To avoid serious injury, the engine must always be

switched off when performing maintenance work on

the lawnmower.

Before carrying out maintenance work, the ignition

lead must always be disconnected and fastened

away from the spark plug in order to prevent the

engine from being started inadvertently.

IMPORTANT

1

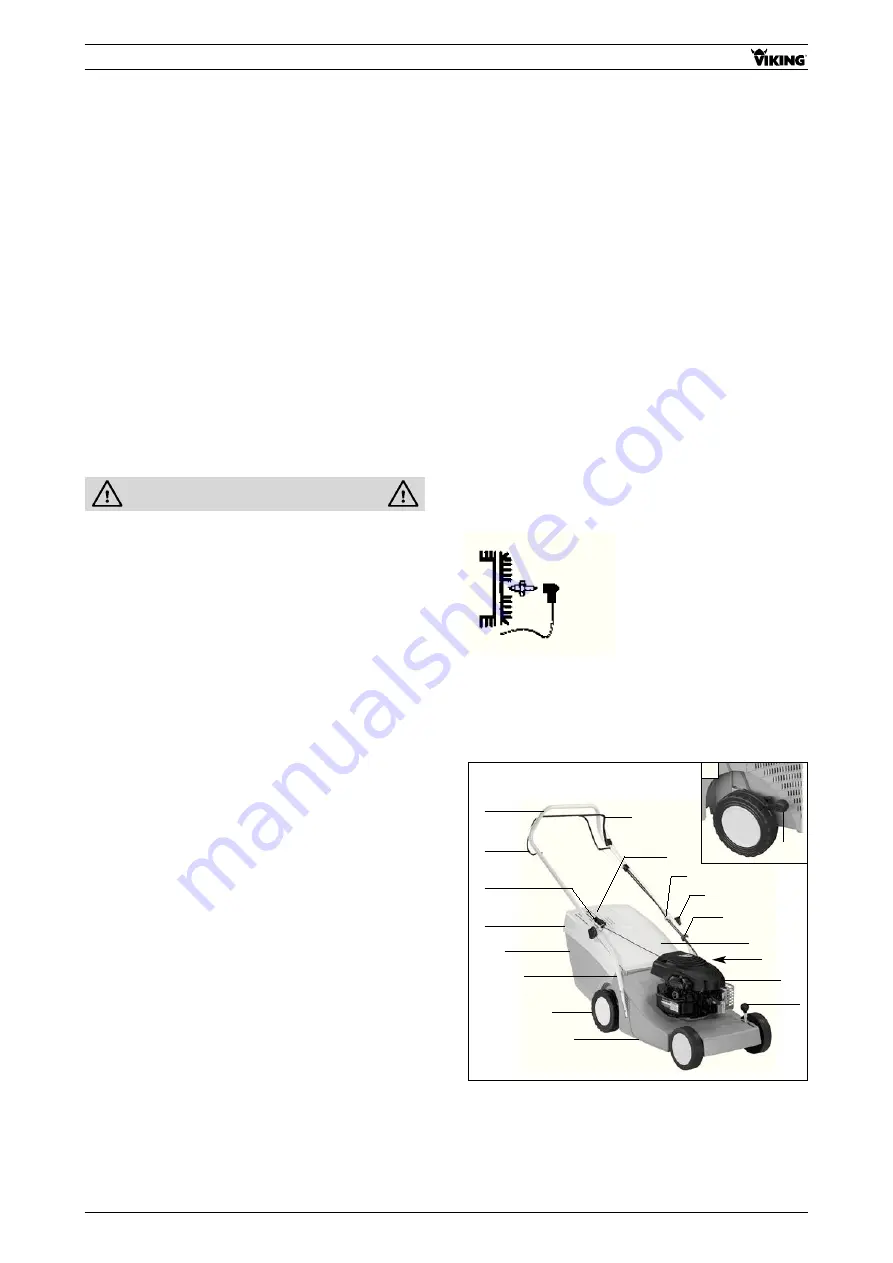

Upper control arm

2

Motorstop lever

3

Starter cable

4

Upper part of catcher

bag

5

Lower part of catcher

bag

6

Lower parts of control

arm

7

Wheels

8

Housing

9

Cutting height

adjustment, front axle

10 Cutting height

adjustment, rear axle

11 Engine

12 Ejection flap

13 Cable clip

14 Rotary handle

15 Cable guide

16 Level indicator

17 Drive lever

2.

Appliance overview

17

16

14

13

12

A

11

9

1

2

3

4

5

6

7

8

15

A

10