ACTIVATE

CONTROLS

LOWER

DISPLAY

OFF

ACTIVATE

CONTROLS

HIGHER

DISPLAY

OFF

ACTIVATE

CONTROLS

HIGHER

ALARM

OFF

Operation

8

©2012 Viking Preferred Service

Forced defrost will terminate when defrost

terminator opens (completion of cycle

defrost) or if forced pull-down is initiated or if

there is a long power loss..

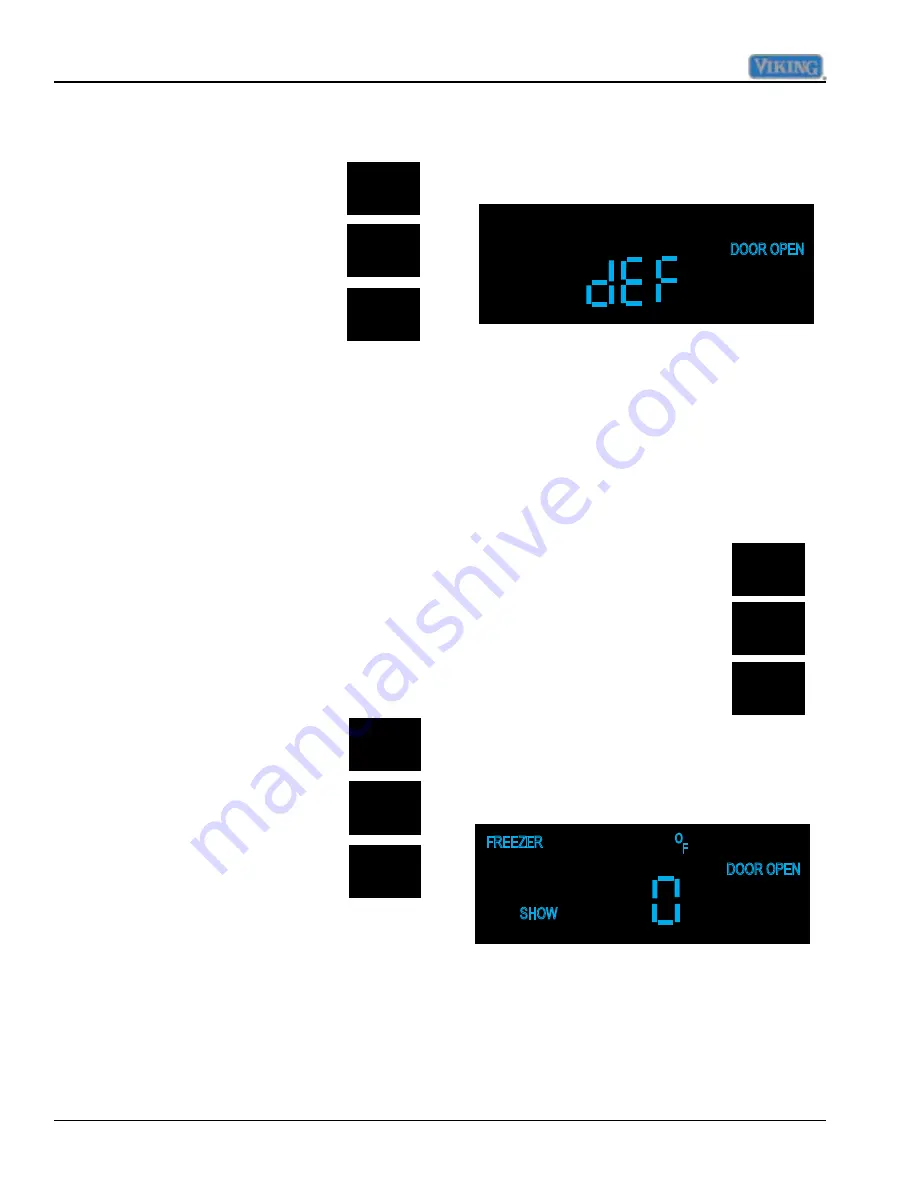

To enter Showroom mode:

Press and hold the “ACTIVATE

CONTROLS” pad. While

holding, press and hold the

“HIGHER” and “ALARM OFF”

pad simultaneously. Continue

holding until three beeps

are heard and then "SHOW"

is illuminated along with

Refrigerator and 38

O

F or Freezer and

0

O

F. Whichever section was active prior

to to showroom mode being entered will

determine which one is displayed.

When forced defrost is initiated the

temperature numbers are replaced with

"dEF" in the seven segment displays, as

shown above. When defrost is complete the

displayed "dEF" will again be replaced with

displayed temperature numerals.

Showroom Mode

To exit Showroom mode: Press and hold the

“ACTIVATE CONTROLS” pad. While holding,

press and hold the “HIGHER” and “ALARM

OFF” pad simultaneously. Continue holding

until three beeps are heard. The display will

revert to normal operation

To enter Forced defrost, first

press and release "ACTIVATE

CONTROLS", then press and hold

"HIGHER" pad, then press and hold

"DISPLAY OFF" pad until you get an

audible consisting of three beeps.

This causes the control to

immediately suspend all

temperature control operations

and start a defrost cycle, regardless of

compressor dwell time and defrost start delay.

If defrost terminator temperature is satisfied

defrost heaters will come on at this time for a

normal defrost cycle.

To enter Forced pull-down, first

press and release "ACTIVATE

CONTROLS", then press and hold

"LOWER" pad, then press and hold

"DISPLAY OFF" pad also until you

get an audible consisting of three

beeps.

This causes the control to

immediately energize the

appropriate outputs in an effort to reach both

of the cut-out temperatures (refrigerator and

freezer).

Forced Pull-Down (Forced compressor

start)

This function will ignore compressor dwell

time and cause immediate compressor start

up in the high speed mode (115HZ).

Forced pull-down will terminate after both

cut-out temperatures are met, or if a defrost

or forced defrost is initiated, or if an extended

power loss occurs.

Forced Defrost

Summary of Contents for Quiet Cool VCFB5301

Page 48: ...Schematic 48 2012 Viking Preferred Service 30 All Freezer Schematic Upper Section...

Page 49: ...Schematic 2012 Viking Preferred Service 49 30 All Freezer Schematic Lower Section...

Page 50: ...Schematic 50 2012 Viking Preferred Service 36 All Freezer Schematic Upper Section...

Page 51: ...Schematic 2012 Viking Preferred Service 51 36 All Freezer Schematic Lower Section...

Page 52: ...Wiring Diagrams 52 2012 Viking Preferred Service UPPER SECTION WIRING 30...

Page 53: ...Wiring Diagrams 2012 Viking Preferred Service 53 LOWER SECTION WIRING 30...

Page 54: ...Wiring Diagrams 54 2012 Viking Preferred Service UPPER SECTION WIRING 36...

Page 55: ...Wiring Diagrams 2012 Viking Preferred Service 55 LOWER SECTION WIRING 36...