SPRINKLER GENERAL CARE,

INSTALLATION, AND

MAINTENANCE GUIDE

TECHNICAL DATA

Page 1 of 4

Form No. F_080614 18.10.11 Rev 16.1.P65

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Visit the Viking website for the latest edition of this technical data page.

1. DESCRIPTION -

STANDARD RESPONSE, QUICK RESPONSE, EXTENDED COVERAGE, AND DRY SPRINKLERS

Viking thermosensitive spray sprinklers consist of a small frame and either a glass bulb or a fusible operating element. Available

styles include pendent, flush pendent, concealed pendent, upright, horizontal sidewall, vertical sidewall, or conventional, depending

on the particular sprinkler model selected.

Viking sprinklers are available with various finishes, temperature ratings, responses, and K-Factors to meet design requirements†.

Used in conjunction with one of the corrosion-resistant coatings (for frame style sprinklers), the units provide protection against

many corrosive environments. In addition, the special Polyester or Teflon

®

coatings can be used in decorative applications where

colors are desired.

† Refer to the sprinkler technical data page for available styles, finishes, temperature ratings, responses, and nominal K-Factors for specific sprinkler models.

2. LISTINGS AND APPROVALS

Refer to the Approval Charts on the appropriate sprinkler technical data page(s) and/or approval agency listings.

3. TECHNICAL DATA

Specifications:

Refer to the appropriate sprinkler technical data sheet.

Material Standards:

Refer to the appropriate sprinkler technical data sheet.

4. INSTALLATION

NOTE: Take care not to over-tighten the sprinkler and/or damage its operating parts!

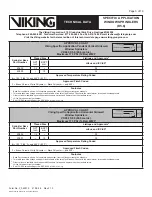

Maximum Torque:

1/2” NPT: 14 ft-lbs. (19.0 N-m)

3/4” NPT: 20 ft-lbs. (27.1 N-m)

1” NPT: 30 ft-lbs. (40.7 N-m)

A. Care and Handling (also refer to Bulletin - Care and Handling of Sprinklers, Form No. F_091699.)

Sprinklers must be handled with care. They must be stored in a cool, dry place in their original shipping container. Never install

sprinklers that have been dropped, damaged, or exposed to temperatures exceeding the maximum ambient temperature al-

lowed (refer to the temperature chart on the sprinkler technical data page). Never install any glass-bulb sprinkler if the bulb is

cracked or if there is a loss of liquid from the bulb. A small air bubble should be present in the glass bulb. Any sprinkler with a

loss of liquid from the glass bulb or damage to the fusible element should be destroyed immediately. (Note: Installing glass bulb

sprinklers in direct sunlight (ultraviolet light) may affect the color of the dye used to color code the bulb. This color change does

not affect the integrity of the bulb.)

Sprinklers must be protected from mechanical damage during storage, transport, handling, and after installation. Sprinklers subject

to mechanical damage must be protected with an approved sprinkler guard.

Use only sprinklers listed as corrosion resistant when subject to corrosive environments. When installing corrosion-resistant sprin-

klers, take care not to damage the corrosion-resistant coating. Use only the special wrench designed for installing coated or

recessed Viking sprinklers (any other wrench may damage the unit).

Concealed sprinklers must be installed in neutral or negative pressure plenums only!

Use care when locating sprinklers near fixtures that can generate heat. Do not install sprinklers where they could be exposed to

temperatures exceeding the maximum recommended ambient temperature for the temperature rating used.

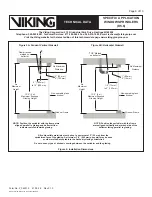

Wet pipe systems must be provided with adequate heat. Sprinklers supplied from dry systems in areas subject to freezing must

be listed dry sprinklers, upright, or horizontal sidewall sprinklers installed so that water is not trapped. For dry systems, pendent

sprinklers and sidewall sprinklers installed on return bends are permitted, where the sprinklers, return bend, and branch line

piping are in an area maintained at or above 40 °F (4 °C).

B. Installation Instructions - Standard Spray Sprinklers

Viking sprinklers are manufactured and tested to meet the rigid requirements of approving agencies. They are designed to be

installed in accordance with recognized installation standards. Deviation from the standards or any alteration to sprinklers or cover

plate assemblies after they leave the factory including, but not limited to: painting, plating, coating, or modification, may render them

inoperative and will automatically nullify the approvals and any guarantee made by The Viking Corporation.

Replaces Form No. F_080614 Rev 16.1

(Added P65 Warning.)