Refrigerating Specialties Division

9

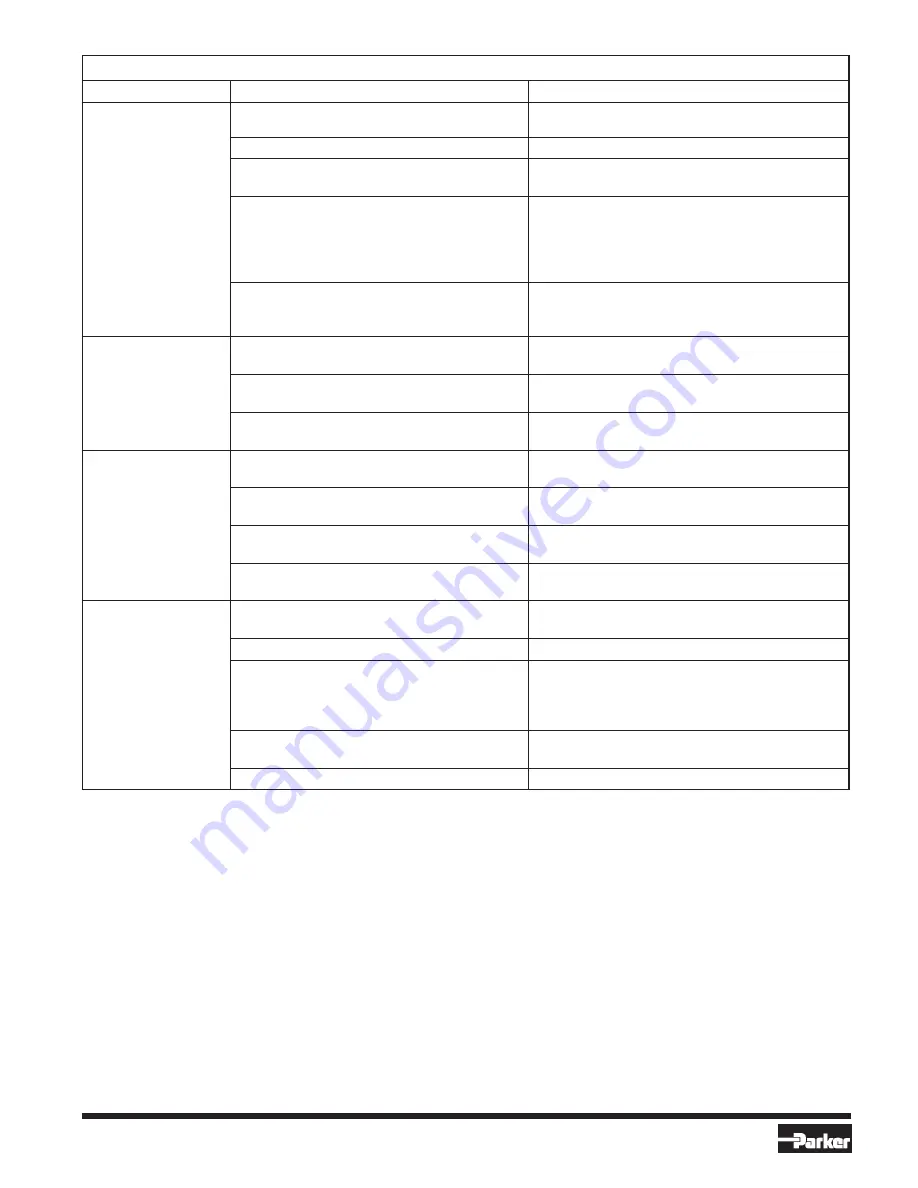

SERVICE POINTERS (Check General Procedure)

SYMPTOM

PROBABLE REASON

CORRECTION

Regulator does not

Diaphragm or seat dirty, damaged or frozen.

Clean or replace. Clean strainer.

shut off flow.

Diaphragm follower stuck or damaged.

Clean or replace. Install follower carefully.

Piston jammed with excess dirt.

Remove and polish piston and bore with

crocus cloth. Clean valve and strainer.

Throttling plug leaking due to excess

Clean or replace. If used on liquid, check for

dirt or damage.

erosion due to excessive flash gas. Reduce

flash gas by sub-cooling or by reducing

pressure drop across valve by providing

restriction at valve outlet.

Diaphragm and seat eroded due to flash gas.

Replace. Reduce flash gas by sub-cooling or by

reducing pressure drop across regulator by

providing restriction at valve outlet.

Regulator does not

A4A (inlet) Pressure Regulator Diaphragm

Replace. If Range D make sure has 2

open.

ruptured or badly deformed.

diaphragms.

Diaphragm follower stuck, damaged

Clean or replace. Install follower carefully.

or frozen.

Piston worn, too much clearance.

Replace piston. Check for reason. If used on

liquid, check for flash gas.

Regulator Operation

Diaphragm or seat dirty or damaged.

Clean or replace. Clean strainer.

erratic.

Diaphragm follower has dirt on the outside

Clean or replace.

diameter or outside diameter is damaged.

Other system components, line controllers,

Adjust, repair or replace.

thermostats, etc. , erratic.

Regulator too far oversized.

Check load. Replace with smaller regulator or

investigate use of Reduced Capacity Plug Kit.

Pressure drop across

Inlet or outlet restricted.

Check for restriction. Clean strainer.

regulator too high.

Regulator too small.

Replace with proper size regulator.

Large amount of flash gas in liquid line.

Reduce flash gas by sub-cooling. Reduce line

restriction by increasing line size, particularly

at the regulator outlet. Replace with larger

regulator.

High pressure drop causes high rate of

Increase pipe size at the outlet of the

expansion of gas at regulator outlet.

regulator.

Regulator does not open all the way.

Check piston for wear. Replace, if needed.

Summary of Contents for VSM 71-701

Page 1: ...1 VPN 35391S February 2006 Rev 05 Price 60 00...

Page 2: ...2...

Page 20: ...20...

Page 52: ...53 Pre Start Up Check List...

Page 99: ...99 Recommended Spare Parts List...

Page 104: ...104 Gate Rotor...

Page 110: ...110 Main Rotor VSS...

Page 112: ...112 Main Rotor VSR...

Page 114: ...114 Slide Valve Cross Shafts and End Plate...

Page 118: ...118 Capacity Slide Volume Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 134: ...134 Miscellaneous Frame Components VSS Screw Compressor VSR Mini Screw Compressor...

Page 138: ...138 C FlangeAdapter Components 630 620 610 640 601 641 630 601 620 610 640 641 642 650 651...

Page 140: ...140 Replacement Parts Tools...

Page 144: ...144 GaterotorAssembly...

Page 148: ...148 Main Rotor Slide Valve Cross Shafts and End Plate Models 71 401 Only Counter clockwise...

Page 152: ...152 Main Rotor Slide Valve Cross Shafts and End Plate Model 501 701 Only Clockwise...

Page 154: ...154 Volume Ratio Capacity Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 158: ...158 Miscellaneous Frame Components Model VSM 501 701 Model VSM 71 401...

Page 160: ...160 Replacement Parts Accessories Housing Accessories C Flange Assembly...

Page 166: ...166 Haight Pumps...

Page 170: ...3 Refrigerating Specialties Division...

Page 236: ......

Page 237: ......

Page 238: ......

Page 243: ......

Page 244: ...168...