8

FAST HEAT, INC.

STANDARD

CARTRIDGE HEATERS

STANDARD CARTRIDGES

Our Standard Cartridge heaters are

designed as an economical, quality heater

for lower temperature use (typically 40

watts per square inch, depending on the

application). Standard Cartridges can meet

U.L./C.S.A. approval, use the chart on page

151 for reference and consult factory.

The Standard Cartridge Heater is made to

withstand internal temperatures of up to

1000º F (538º C) and features a stainless

steel sheath for resistance to oxidation.

High-purity magnesium oxide (MgO) fills

any space around the resistor wire in order

to optimize heat transfer and increase the

life of the heater.

For faster shipment, Standard Cartridges are

available through our Fast Track delivery

program. Refer to page 2 for a complete

description of these rapid delivery programs.

APPLICATIONS

Standard Cartridge heaters can be used in

virtually any application involving lower

temperatures and relatively little vibration or

impact. Some examples include sealing bars,

heating platens, heating fluids and forming.

Standard Cartridges can also be modified to

meet the demands of special applications.

Our engineers can utilize a variety of alterna-

tive features and options to customize the

heater to your specific needs.

FEATURES AND BENEFITS

• Wide range of diameters.

• Many termination styles.

• Voltage variations.

• U.L. approved and C.S.A. recognized.

• Top quality ceramic element support.

• Unique winding design allows faster

heating and longer life.

• High purity MgO packing for even

heat distribution.

• Fiberglass insulated lead wire is standard.

Other lead wire insulation available

upon request.

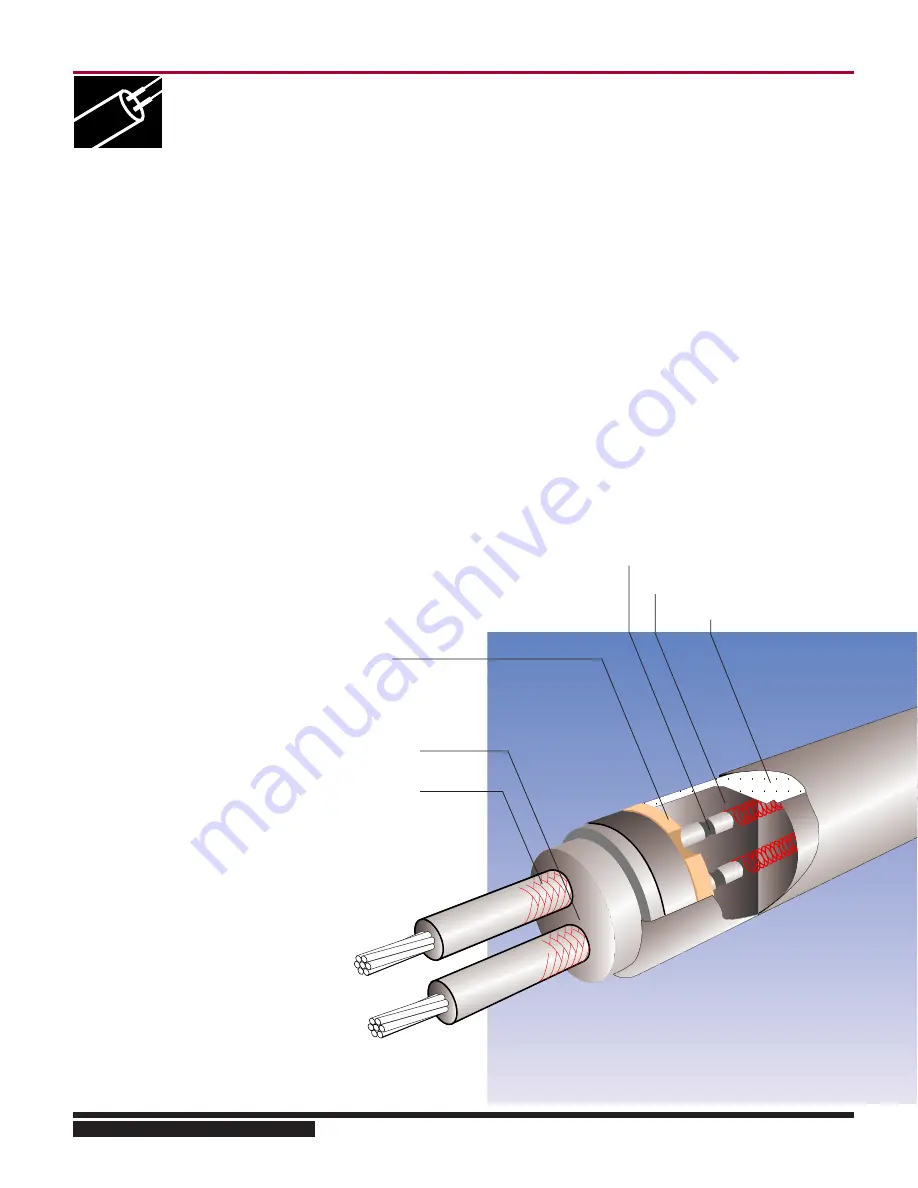

MATERIAL AND CONSTRUCTION

• Computer designed specifications.

• 304 stainless steel sheath for oxidation

resistance.

• Ceramic insulator spaces helically wound

resistor inside the sheath.

• Helically wound nickel chromium resistor

is of a conservative design for each

application and evenly stretched through

the ceramic insulators.

• Fine grain high purity magnesium oxide

(MgO) fills any voids around the resistor

wire to optimize heat transfer, dielectric

strength and life of the heater.

• Resistor wire is joined to the leads by

placing each end into nickel chromium

which, upon crimping, affords a positive

and consistent junction.

• U.L. approved and C.S.A. certified flexible

nickel conductor with fiberglass insulated

lead wire 482º F, (250º C) is standard.

Mica tape/fiberglass insulated 842º F,

(450º C) available when requested

as dictated by the application.

• Disc end of the heater rests on a mica

insulator and is held in position when

the sheath is rolled over onto it. This is a

standard assembly procedure unless the

application requires moisture or water-

proof sealing, at which time the end cap

can be sealed by brazing or welding.

• Ceramic cap standard; cement, epoxy or

RTV seal also available.

Ceramic cap

Lead wire

Spacer

Crimped tubing

Core

MgO

THE STANDARD CARTRIDGE HEATER

Summary of Contents for VSM 71-701

Page 1: ...1 VPN 35391S February 2006 Rev 05 Price 60 00...

Page 2: ...2...

Page 20: ...20...

Page 52: ...53 Pre Start Up Check List...

Page 99: ...99 Recommended Spare Parts List...

Page 104: ...104 Gate Rotor...

Page 110: ...110 Main Rotor VSS...

Page 112: ...112 Main Rotor VSR...

Page 114: ...114 Slide Valve Cross Shafts and End Plate...

Page 118: ...118 Capacity Slide Volume Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 134: ...134 Miscellaneous Frame Components VSS Screw Compressor VSR Mini Screw Compressor...

Page 138: ...138 C FlangeAdapter Components 630 620 610 640 601 641 630 601 620 610 640 641 642 650 651...

Page 140: ...140 Replacement Parts Tools...

Page 144: ...144 GaterotorAssembly...

Page 148: ...148 Main Rotor Slide Valve Cross Shafts and End Plate Models 71 401 Only Counter clockwise...

Page 152: ...152 Main Rotor Slide Valve Cross Shafts and End Plate Model 501 701 Only Clockwise...

Page 154: ...154 Volume Ratio Capacity Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 158: ...158 Miscellaneous Frame Components Model VSM 501 701 Model VSM 71 401...

Page 160: ...160 Replacement Parts Accessories Housing Accessories C Flange Assembly...

Page 166: ...166 Haight Pumps...

Page 170: ...3 Refrigerating Specialties Division...

Page 236: ......

Page 237: ......

Page 238: ......

Page 243: ......

Page 244: ...168...