20

FAST HEAT, INC.

CARTRIDGE

HEATERS

APPLICATION FOR SELECTION OF

CARTRIDGE HEATERS IN PLATENS

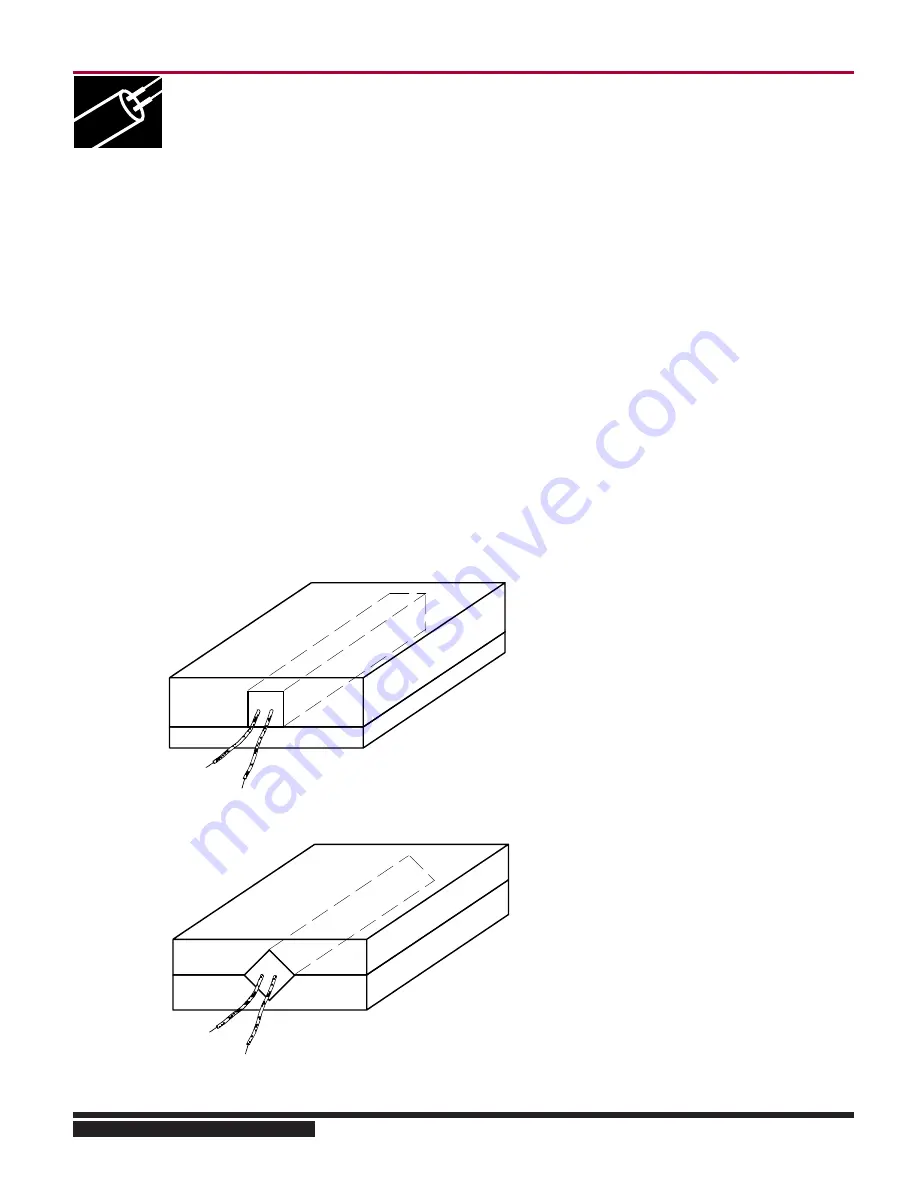

Whether round or square cartridges are

used, close contact of the heater to the

component being heated is important.

When the application is such that the hole

into which a round heater is to be inserted is

too long for practical drilling and reaming, a

Square Cartridge can be selected.

By considering a split plate design, platen

recesses for the Square heater can be milled

for greater lengths or to keep the machine

in-house.

For even heating along the length of the

heaters, consider distributed wattage.

If terminations are protected by a wire

enclosure box and the platen is operating in

excess of 450º F (232º C), consider specifying

high temperature mica tape leads.

To leads that are flexing, add clip supports;

where there is abrasion, cover the leads with

stainless steel braid. For possible contamina-

tion, request armor.

PRECISION STANDARD SQUARE

CARTRIDGE HEATERS

Our Square Cartridge heaters,

3

/

8

”

(9.5 mm),

1

/

2

”

(12.7 mm), and

5

/

8

”

(15.9 mm) square,

provide more surface area contact than

cylindrical types. Square Cartridge heaters

are normally inserted in a milled slot, there-

fore permitting greater lengths than would

be practically feasible with a drilled or

reamed hole.

As with our Standard Cartridge, Fast Heat’s

Square Cartridge heater features a stainless

steel sheath for resistance to oxidation and

can withstand internal temperatures of up

to 1000º F (538º C). In order to optimize heat

transfer and lengthen the life of the heater,

high-purity magnesium oxide (MgO) insula-

tion fills any space around the resistor wire.

APPLICATIONS

Square Cartridge heaters can be used in

virtually any application involving average

temperatures and vibration. Some examples

include sealing bars, heating platens,

heating fluids and forming.

Square Cartridges can also be modified to

meet the demands of virtually any special

application. Our engineers can utilize a vari-

ety of alternative features and options to

customize the heater to your specific needs.

Summary of Contents for VSM 71-701

Page 1: ...1 VPN 35391S February 2006 Rev 05 Price 60 00...

Page 2: ...2...

Page 20: ...20...

Page 52: ...53 Pre Start Up Check List...

Page 99: ...99 Recommended Spare Parts List...

Page 104: ...104 Gate Rotor...

Page 110: ...110 Main Rotor VSS...

Page 112: ...112 Main Rotor VSR...

Page 114: ...114 Slide Valve Cross Shafts and End Plate...

Page 118: ...118 Capacity Slide Volume Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 134: ...134 Miscellaneous Frame Components VSS Screw Compressor VSR Mini Screw Compressor...

Page 138: ...138 C FlangeAdapter Components 630 620 610 640 601 641 630 601 620 610 640 641 642 650 651...

Page 140: ...140 Replacement Parts Tools...

Page 144: ...144 GaterotorAssembly...

Page 148: ...148 Main Rotor Slide Valve Cross Shafts and End Plate Models 71 401 Only Counter clockwise...

Page 152: ...152 Main Rotor Slide Valve Cross Shafts and End Plate Model 501 701 Only Clockwise...

Page 154: ...154 Volume Ratio Capacity Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 158: ...158 Miscellaneous Frame Components Model VSM 501 701 Model VSM 71 401...

Page 160: ...160 Replacement Parts Accessories Housing Accessories C Flange Assembly...

Page 166: ...166 Haight Pumps...

Page 170: ...3 Refrigerating Specialties Division...

Page 236: ......

Page 237: ......

Page 238: ......

Page 243: ......

Page 244: ...168...