INSTALLATION OF CARBON

GRAPHITE BUSHINGS

When installing carbon graphite bushings, extreme care

must be taken to prevent breaking. Carbon graphite is a

brittle material and easily cracked. If cracked, the bushing

will quickly disintegrate. Using a lubricant and adding a

chamfer on the bushing and the mating part will help in

installation. The additional precautions listed below must

be followed for proper installation:

1.

A press must be used for installation.

2.

Be certain bushing is started straight.

3.

Do not stop pressing operation until bushing is in

proper position, starting and stopping will result in a

cracked bushing.

4.

Check bushing for cracks after installation.

THRUST BEARING ADJUSTMENT

See Figures 9 and 10.

Loosen two screws in face of thrust bearing assembly.

If shaft cannot be rotated freely, turn thrust bearing

assembly counterclockwise until shaft can be turned

easily.

To set end clearance:

1.

While turning rotor shaft, rotate thrust bearing

assembly clockwise until noticeable drag occurs.

This is zero end clearance.

2.

Mark position of bearing housing with respect to the

casing.

3.

Rotate thrust bearing assembly counterclockwise the

distance listed below as measured on outside of

bearing housing.

4.

Tighten two setscrews in face of bearing housing

after adjustment is made to secure thrust bearing

assembly position.

For viscosities above 2500 SSU, add additional end

clearance (0.004” for GG, HJ and HL size pumps

and 0.005” for AS, AK and AL size pumps).

DANGER

BEFORE STARTING PUMP, BE SURE ALL

DRIVE EQUIPMENT GUARDS ARE IN PLACE.

FAILURE TO PROPERLY MOUNT GUARDS

MAY RESULT IN SERIOUS INJURY OR DEATH.

12.

Pack inner ball bearing with multi-purpose grease,

NLGI #2.

GG, HJ, HL:

Install bearing in casing with sealed side

towards head end of pump. Drive the

bearing into the bore. Tap the inner race

with a brass bar and lead hammer to

position bearing.Install inner snap ring.

AS, AK, AL:

Install bearing retainer washer over the

shaft before installing ball bearing. Install

ball bearing in casing with sealed side

towards head end of pump. Drive the

bearing into the bore. Tap the inner race

with a brass bar and lead hammer to

position bearing.

13. GG, HJ, HL:

Install shaft snap ring in groove in the

shaft. See Figure 9.

AS, AK, AL:

Install bearing spacer over shaft and

against single row ball bearing. See

Figure 10.

14.

Pack lubrication chamber between inner ball bearing

and double row ball bearing in the thrust bearing

assembly approximately one-half full of multi-purpose

grease, NLGI #2. The thrust bearing assembly will take

the remaining space. See Figure 9 and 10.

15.

Pack double row ball bearing with multi-purpose

grease, NLGI #2.

GG, HJ, HL:

Install ball bearing into bearing housing

with shield side toward coupling end of shaft. See

Figure 9. Install snap ring into bearing housing to

retain ball bearing. This snap ring has a tapered edge

to fit tapered groove in bearing housing. The tapered

edge is located away from ball bearing.

AS, AK, AL:

Install ball bearing into bearing housing.

Install lip seal in bearing housing end cap. The lip

should face towards end of shaft. Put bearing spacer

collar in lip seal and install in bearing housing and

tighten set screws securely. See Figure 10.

16.

Insert brass bar or hardwood through port opening

between rotor teeth to keep shaft from turning.

17.

Start thrust bearing assembly into casing. Turn by

hand until tight. This forces rotor against head.

Replace and tighten locknut or shaft.

18.

Remove brass bar or hardwood from port opening.

19.

Adjust pump end clearance, refer to page 7.

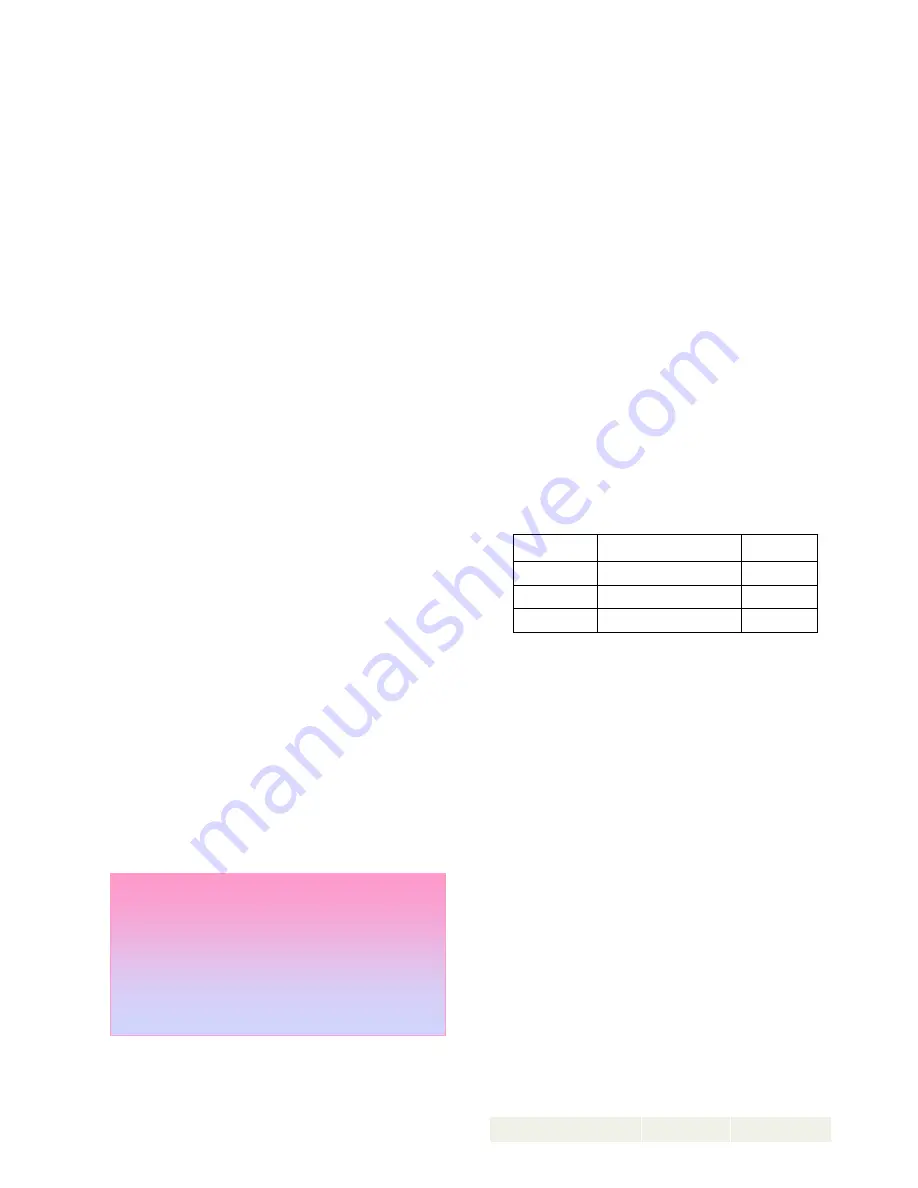

Pump Size

Distance In Inches On

O.D. Of Bearing Housing

End

Clearance

GG 0.44”

.003

HJ, HL

0.56”

.003

AS, AK, AL

0.5”

.003

SECTION TSM 144

ISSUE B

PAGE 7 OF 9

Summary of Contents for VSM 71-701

Page 1: ...1 VPN 35391S February 2006 Rev 05 Price 60 00...

Page 2: ...2...

Page 20: ...20...

Page 52: ...53 Pre Start Up Check List...

Page 99: ...99 Recommended Spare Parts List...

Page 104: ...104 Gate Rotor...

Page 110: ...110 Main Rotor VSS...

Page 112: ...112 Main Rotor VSR...

Page 114: ...114 Slide Valve Cross Shafts and End Plate...

Page 118: ...118 Capacity Slide Volume Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 134: ...134 Miscellaneous Frame Components VSS Screw Compressor VSR Mini Screw Compressor...

Page 138: ...138 C FlangeAdapter Components 630 620 610 640 601 641 630 601 620 610 640 641 642 650 651...

Page 140: ...140 Replacement Parts Tools...

Page 144: ...144 GaterotorAssembly...

Page 148: ...148 Main Rotor Slide Valve Cross Shafts and End Plate Models 71 401 Only Counter clockwise...

Page 152: ...152 Main Rotor Slide Valve Cross Shafts and End Plate Model 501 701 Only Clockwise...

Page 154: ...154 Volume Ratio Capacity Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 158: ...158 Miscellaneous Frame Components Model VSM 501 701 Model VSM 71 401...

Page 160: ...160 Replacement Parts Accessories Housing Accessories C Flange Assembly...

Page 166: ...166 Haight Pumps...

Page 170: ...3 Refrigerating Specialties Division...

Page 236: ......

Page 237: ......

Page 238: ......

Page 243: ......

Page 244: ...168...