Page 6

/ BULLETIN 10-11

If in doubt about the correct superheat setting for a particular system,

consult the equipment manufacturer. As a general rule, the proper

superheat setting will depend on the amount of temperature differ-

ence

(TD)

between refrigerant temperature and the temperature of the

air or other substance being cooled. Where high

TD’s

exist, such as

on air conditioning applications, the superheat setting can be made as

high as 15°F without noticeable loss in evaporator capacity. Where

low

TD’s

exist, such as in low temperature blower coil applications,

a superheat setting of 10°F or below is usually recommended for

maximum evaporator capacity. It is these applications that the TEV

will more than likely need to be adjusted.

For the correct valve setting on factory built equipment, manufac-

turers’ recommendations should be followed. Some manufacturers

specify the superheat directly; others may recommend valve adjust-

ment to a given suction pressure at certain operating conditions, or

until a certain frost line is observed. Such recommendations, however

they are stated, represent the results of extensive laboratory testing to

determine the best possible operation.

Field Servicing

The TEV is erroneously considered by some to be a mysterious and

complex device. As a result, many valves are needlessly replaced

when the cause of the system malfunction is not immediately

recognized.

Actually the TEV performs only one very simple function –

it keeps

the evaporator supplied with enough refrigerant to satisfy

all load conditions

. It is not a temperature control, suction

pressure control, a control to vary the compressor’s running time, or

a humidity control.

How effective the valve performs is easily determined by measuring

the superheat as outlined in Figure 8. Observing the frost on the

suction line, or considering only the suction pressure may be

misleading.

Checking the superheat is the first step in a

simple and systematic analysis of TEV performance.

■

If not enough refrigerant is being fed to the evaporator—

the superheat will be high.

■

If too much refrigerant is being fed to the evaporator —

the superheat will be low.

Although these symptoms may be attributed to improper TEV

control, more frequently the origin of the trouble lies elsewhere.

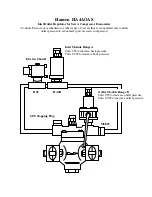

Note:

TEVs with permanent bleed ports

(BP)

or Rapid Pressure

Balancer

(RPB)

construction are applied on many air conditioning

and refrigeration systems by original equipment manufacturers. Each

application is tested and approved by the manufacturer. The primary

function of these devices is to equalize high-to-low side pressures

during the off cycle on systems equipped with low starting torque

compressors.

However, some BP type valves are applied to allow small amounts of

liquid refrigerant to pass for compressor motor cooling. The specific

function of the feature on a given unit must be determined from the

system manufacturer. Once that is determined, it is easier to

troubleshoot the system.

The primary cause of difficulty with either the BP or RPB feature is

dirt and other foreign materials that restrict or plug them. And if the

system purpose intended for either feature is not being satisfied, the

valve probably needs cleaning or replacing.

As stated in Bulletin 10-9, the RPB type valve is not to be applied on

systems using high starting torque compressors or “hard-start”

electrical components, on outdoor coils of heat pumps, or on any

refrigeration system, and it should

not

be used to replace BP type

valves that are applied on those types of systems. On systems other

than those described above, the RPB type valve can replace the BP

type valve when necessary. Usually it is advisable to replace a valve

with one of the same specification unless advised differently. Consult

with the system manufacturer for assistance.

Complaint "A"

“Valve does not feed enough refrigerant.”

SYMPTOMS:

■

Load temperature (air or water leaving

evaporator) too high.

■

Superheat too high.

■

Suction pressure lower than normal with

compressor unloaders locked out or hot gas

bypass shut off.*

THE CAUSE MAY BE:

1. Moisture

— Water or a mixture of water and oil frozen in the

valve port or working parts of the valve will prevent proper

operation. This is a common source of trouble on expansion

valves. Since the valve is the first cold spot in the system,

moisture will freeze and block the valve open, closed, or any

position in between. If the valve is frozen in the intermediate

position so that flow is restricted, the superheat will be high.

Remedy

— Install a Sporlan Catch-All Filter-Drier in the

liquid line for removal of moisture from the refrigerant and oil.

See Bulletin 40-10.

To determine a safe level of moisture in the system, install a

Sporlan See•All Moisture and Liquid Indicator. See Bulletin

70-10.

Excessive moisture has a damaging effect on all

system components regardless of the evaporating

temperature. Moisture must be removed for trouble-

free performance.

2. Dirt or foreign material

— Contaminants such as copper

oxide scale, metal chips, oil breakdown sludge, etc. will restrict

the flow of refrigerant when it collects in strainers or other liquid

line accessories. This produces a shortage of refrigerant at the

TEV port. Conventional strainers frequently allow the material

to pass through the screen and obstruct the flow at the valve

port. If a See•All is installed downstream of the restriction,

bubbles will be visible. This should not be confused, however,

with a refrigerant shortage or excessive liquid line pressure loss

which are also indicated by bubbles in the See•All.

Remedy

— Locate and remove the foreign material creating

the restriction. Install a Sporlan Catch-All Filter-Drier to

provide effective filtration of the refrigerant. See Bulletin 40-10.

*

When system has some form of capacity reduction — cylinder unloaders or hot gas bypass, a low suction pressure will not exist. Therefore, when checking TEV

performance, a better analysis is possible when these devices are locked out or shut off so the suction pressure will respond to variations in load or valve feed.

Summary of Contents for VSM 71-701

Page 1: ...1 VPN 35391S February 2006 Rev 05 Price 60 00...

Page 2: ...2...

Page 20: ...20...

Page 52: ...53 Pre Start Up Check List...

Page 99: ...99 Recommended Spare Parts List...

Page 104: ...104 Gate Rotor...

Page 110: ...110 Main Rotor VSS...

Page 112: ...112 Main Rotor VSR...

Page 114: ...114 Slide Valve Cross Shafts and End Plate...

Page 118: ...118 Capacity Slide Volume Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 134: ...134 Miscellaneous Frame Components VSS Screw Compressor VSR Mini Screw Compressor...

Page 138: ...138 C FlangeAdapter Components 630 620 610 640 601 641 630 601 620 610 640 641 642 650 651...

Page 140: ...140 Replacement Parts Tools...

Page 144: ...144 GaterotorAssembly...

Page 148: ...148 Main Rotor Slide Valve Cross Shafts and End Plate Models 71 401 Only Counter clockwise...

Page 152: ...152 Main Rotor Slide Valve Cross Shafts and End Plate Model 501 701 Only Clockwise...

Page 154: ...154 Volume Ratio Capacity Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 158: ...158 Miscellaneous Frame Components Model VSM 501 701 Model VSM 71 401...

Page 160: ...160 Replacement Parts Accessories Housing Accessories C Flange Assembly...

Page 166: ...166 Haight Pumps...

Page 170: ...3 Refrigerating Specialties Division...

Page 236: ......

Page 237: ......

Page 238: ......

Page 243: ......

Page 244: ...168...