Page 8

/ BULLETIN 10-11

flowing through the evaporator, check the piping for possible

refrigerant flow from another evaporator affecting the bulb. Re-

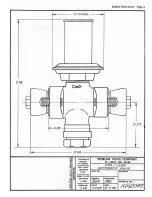

pipe if necessary. See Figure 4.

13. High pressure drop through evaporator

Remedy

— Check the pressure at the evaporator inlet and

outlet with gauges. If pressure difference is greater than the

values shown in Table 1, Bulletin 10-9, use an externally

equalized valve.

14. Restricted, plugged, or capped external equalizer

—

If the pressure under the diaphragm builds up due to pushrod

leakage and cannot escape through the external equalizer line,

the valve will remain closed.

Remedy

— Check the external equalizer line to be sure it is

open or not capped.

Complaint "B"

“Valve feeds too much refrigerant.”

SYMPTOMS:

■

Liquid returns to compressor.

■

Superheat is low.

■

Suction pressure is normal or higher than

normal.

THE CAUSE MAY BE:

1. Moisture

— Water or a mixture of water and oil frozen in the

valve port or working parts of the valve will prevent proper

operation. This is the most common source of trouble on TEVs.

Since the valve is the first cold spot in the system, moisture will

freeze and block the valve open, closed, or any position in

between. If the valve is held in the open position by ice, liquid

flood-back will occur.

Remedy

— Install a Sporlan Catch-All Filter-Drier in the

liquid line for removal of moisture from the refrigerant and oil.

See Bulletin 40-10.

For additional protection, install a Sporlan See•All Moisture and

Liquid Indicator for a positive indication of when a safe

moisture level is reached. See Bulletin 70-10.

2. Dirt or foreign material

— Contaminants such as copper

oxide scale, metal chips, oil breakdown sludge, etc. may pass

through ordinary strainers and lodge at the TEV port and prevent

the valve from closing.

Remedy

— Disassemble the valve and remove all foreign

material from the internal parts. Install a Sporlan Catch-All

Filter-Drier in the liquid line. The Catch-All filters out the

smallest particles of foreign material that might interfere with

the operation of any system component.

3. Expansion valve seat leak

— When the valve port does

not seat tightly, refrigerant will pass through during the off-cycle

and fill the evaporator with refrigerant. If the seat leak is severe,

the valve will feed too much refrigerant during the operating

cycle as well. (Not applicable to valves with permanent bleed

ports or RPB feature.)

Remedy

— If the valve seat is leaking, a gurgling or hissing

sound can usually be heard during the off-cycle. Also, a sight

glass or See•All in the liquid line may indicate continued refrig-

erant flow for a long period after the compressor has stopped.

Make certain however, that the bubbles are not the result of

back-flow

through a vertical liquid line.

Disassemble the valve to be certain that dirt or foreign material

is not responsible (see

B-2

). If the pin and seat are worn or

damaged and an internal parts kit is available, replace the parts.

When parts are not available, the valve must be replaced.

4. Oversized valve

— Check valve ratings considering all the

factors which affect its capacity. See Page 16, Bulletin 10-9, or

Page 3, Bulletin 10-10.

Remedy

— Install correctly sized valve.

5. Incorrect bulb installation

— The bulb should be securely

fastened to a straight, clean, section of the suction line using two

bulb straps for good thermal contact. Also, the temperature of the

bulb should not be influenced by ambient temperature — an

external heat source such as a steam pipe or heating coil.

Remedy

— Install bulb correctly. See Bulb Location and

Installation, Page 2.

6. Low superheat adjustment

Remedy

— Turn the adjusting stem clockwise until the correct

superheat is indicated. See Page 4.

7. Incorrect thermostatic charge

Remedy

— Select and install the correct selective charge. See

Bulletin 10-9.

8. Incorrectly located external equalizer

Remedy

— Relocate external equalizer or the connection

between evaporator and any other temperature or pressure

sensitive evaporator control valve near bulb location. See Page

3 for recommendations.

9. Inefficient compressor

— If the compressor is inefficient

or for some other reason lacks capacity, the suction pressure will

operate higher than normal. This may or may not be accompa-

nied by low superheats.

Remedy

— Consult with compressor manufacturer.

Complaint "C"

“Valve feeds too much refrigerant at start-up only.”

SYMPTOMS:

■

Liquid returns to compressor.

■

No superheat.

■

Suction pressure higher than normal.

THE CAUSE MAY BE:

1. Refrigerant drainage

— Drainage of refrigerant from the

evaporator (during the off-cycle) when installed at a higher level

than the compressor.

Remedy

— Install a trap-riser to top of evaporator or use

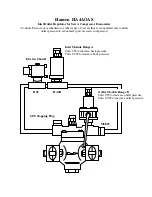

pump-down control. See Figure 5.

2. Compressor or suction line in cold location

—

During the period when the system is not in operation, liquid

refrigerant will condense at the coldest point in the system. Liquid

will condense in the compressor or suction line, if they are located

in an ambient temperature below that of the evaporator during the

off-cycle. Upon re-starting, this liquid will slug the compressor.

Remedy

— Keep compressor or suction line warm during the

off-cycle. Some compressors are equipped with crankcase heaters

Summary of Contents for VSM 71-701

Page 1: ...1 VPN 35391S February 2006 Rev 05 Price 60 00...

Page 2: ...2...

Page 20: ...20...

Page 52: ...53 Pre Start Up Check List...

Page 99: ...99 Recommended Spare Parts List...

Page 104: ...104 Gate Rotor...

Page 110: ...110 Main Rotor VSS...

Page 112: ...112 Main Rotor VSR...

Page 114: ...114 Slide Valve Cross Shafts and End Plate...

Page 118: ...118 Capacity Slide Volume Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 134: ...134 Miscellaneous Frame Components VSS Screw Compressor VSR Mini Screw Compressor...

Page 138: ...138 C FlangeAdapter Components 630 620 610 640 601 641 630 601 620 610 640 641 642 650 651...

Page 140: ...140 Replacement Parts Tools...

Page 144: ...144 GaterotorAssembly...

Page 148: ...148 Main Rotor Slide Valve Cross Shafts and End Plate Models 71 401 Only Counter clockwise...

Page 152: ...152 Main Rotor Slide Valve Cross Shafts and End Plate Model 501 701 Only Clockwise...

Page 154: ...154 Volume Ratio Capacity Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 158: ...158 Miscellaneous Frame Components Model VSM 501 701 Model VSM 71 401...

Page 160: ...160 Replacement Parts Accessories Housing Accessories C Flange Assembly...

Page 166: ...166 Haight Pumps...

Page 170: ...3 Refrigerating Specialties Division...

Page 236: ......

Page 237: ......

Page 238: ......

Page 243: ......

Page 244: ...168...