BULLETIN 10-11 /

Page 9

for this purpose. Another corrective measure is to install a suction

line solenoid valve that is de-energized during the off-cycle.

3. Restricted or plugged external equalizer

— A

momentary flood can occur when the load increases suddenly,

such as at start-up because the higher suction pressure cannot

reach the underside of the diaphragm and help close the valve.

If the pressure under the diaphragm increases due to any

pressure leakage around the pushrods, the valve will eventually

throttle.

Remedy

— Remove the restriction or plugged portion of the

external equalizer.

4. Liquid line solenoid valve seat leak or interrupted

pumpdown

— Liquid refrigerant can continue to feed the

TEV and/or remain in evaporator upon shut-down causing

flood-back to the compressor upon start-up.

Remedy

— Disassemble and clean solenoid valve and/or

replace damaged internal parts if seat leakage is the problem. If

the pumpdown cycle isn’t completed before the compressor

cycles off, or the thermostat calls for cooling and reopens the

liquid line solenoid before the evaporator has been properly

evacuated, check the low pressure cut-off setting or the

electrical controls for possible causes.

Complaint "D"

“Valve doesn't feed properly.”

SYMPTOMS:

■

Poor system performance.

■

Superheat normal or lower than normal.

■

Suction pressure lower than normal with

compressor unloaders locked out or hot gas

bypass shut off.*

THE CAUSE MAY BE:

1. Unequal circuit loading (Multi-circuit evaporators

and parallel evaporators connected to a single

refrigerant distributor)

— When each circuit is not

subjected to the same heat load, the lightly loaded circuits will

allow unevaporated refrigerant or low temperature vapor to

enter the suction line and throttle the valve. This will cause

normally loaded circuits to be deprived of their share of

refrigerant. The net result is a loss of refrigerated evaporator

surface.

Remedy

— Make necessary modifications which will allow

each evaporator circuit to receive the same percentage of the

total load. See Bulletin 20-10 for application information on

multi-circuit evaporators using a refrigerant distributor.

2. Poor refrigerant distribution (Multi-circuit evapora-

tors and parallel evaporators connected to a single

refrigerant distributor)

— If the refrigerant distribution is

faulty, the circuits receiving the largest portion of refrigerant

will have the controlling influence on the TEV. The result is the

same as in paragraph 1 above.

Remedy

— Correct refrigerant distribution. See Bulletin 20-10

for complete information on Refrigerant Distributors.

3. Low load

— Low evaporator load may be caused by insuffi-

cient air over the coil as a result of an undersized blower, dirty

air filters, or an obstruction in the air stream. In addition, frost

formation on the coil or low entering air temperatures will

reduce the evaporator load.

Remedy

— Correct the condition responsible.

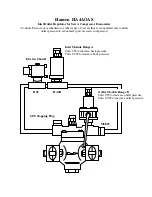

4. Flow from one coil affecting TEV bulb of another

(Multiple evaporator systems only)

— The tempera-

ture of the bulb may be falsely influenced by flow from another

evaporator usually because of incorrect piping.

Remedy

— Correct the piping. See Figure 4, Page 3.

5. Improper compressor-evaporator balance

— If the

compressor is too large for the load and evaporator capacity, the

low suction pressure which results will cause poor system

performance.

Remedy

— Consult with the manufacturer or consulting

engineer, or the ASHRAE Handbook on component balancing.

If necessary, change or correct the improperly sized component.

Hot gas bypass may be used to balance properly.

6. Evaporator oil-logged

— Poor heat transfer occurs and

unpredictable performance takes place. If erratic performance is

observed over a period of time, and other causes are omitted

from consideration, review the amount of oil in the system.

Turbulent compressor oil level with little or no return to the

compressor sump indicates oil problems.

Remedy

— Remove excessive oil from evaporator and

connecting piping. Many times the evaporator temperature will

be too low for the oil to be removed. Therefore, the system must

be allowed to warm sufficiently to get cold oil to drain. Analyze

system components for possible causes of oil problem before

restarting the system. Consult with the compressor manufacturer

for specific details on their compressor.

Complaint "E"

“System hunts or cycles.”

SYMPTOMS:

■

Suction pressure fluctuates*

■

Superheat fluctuates.

■

Valve does not feed enough, and then too much

refrigerant.

THE CAUSE MAY BE:

1. System characteristics

— Certain design characteristics of

the system may have an effect on the system’s tendency to hunt

or cycle. As an example, after the valve admits refrigerant to the

evaporator inlet, there is a time delay before the bulb senses the

effect at the evaporator outlet. This time delay is dependent on

evaporator length, tube size, and load. Generally, there is more

likelihood for hunting to occur when this time interval is long.

Other influencing factors are circuit arrangement, load per

circuit, and temperature difference.

Remedy

— When hunting is moderate particularly with no

floodback, the effect on the system is insignificant and correc-

*

When system has some form of capacity reduction — cylinder unloaders or hot gas bypass, a low suction pressure will not exist. Therefore, when checking TEV

performance, a better analysis is possible when these devices are locked out or shut off so the suction pressure will respond to variations in load or valve feed.

Summary of Contents for VSM 71-701

Page 1: ...1 VPN 35391S February 2006 Rev 05 Price 60 00...

Page 2: ...2...

Page 20: ...20...

Page 52: ...53 Pre Start Up Check List...

Page 99: ...99 Recommended Spare Parts List...

Page 104: ...104 Gate Rotor...

Page 110: ...110 Main Rotor VSS...

Page 112: ...112 Main Rotor VSR...

Page 114: ...114 Slide Valve Cross Shafts and End Plate...

Page 118: ...118 Capacity Slide Volume Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 134: ...134 Miscellaneous Frame Components VSS Screw Compressor VSR Mini Screw Compressor...

Page 138: ...138 C FlangeAdapter Components 630 620 610 640 601 641 630 601 620 610 640 641 642 650 651...

Page 140: ...140 Replacement Parts Tools...

Page 144: ...144 GaterotorAssembly...

Page 148: ...148 Main Rotor Slide Valve Cross Shafts and End Plate Models 71 401 Only Counter clockwise...

Page 152: ...152 Main Rotor Slide Valve Cross Shafts and End Plate Model 501 701 Only Clockwise...

Page 154: ...154 Volume Ratio Capacity Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 158: ...158 Miscellaneous Frame Components Model VSM 501 701 Model VSM 71 401...

Page 160: ...160 Replacement Parts Accessories Housing Accessories C Flange Assembly...

Page 166: ...166 Haight Pumps...

Page 170: ...3 Refrigerating Specialties Division...

Page 236: ......

Page 237: ......

Page 238: ......

Page 243: ......

Page 244: ...168...