Page 10

/ BULLETIN 10-11

tions are not necessary. If hunting is severe with floodback to

the compressor, check the possible remedies shown in

paragraphs below.

2. Valve size

— An over-sized valve usually aggravates hunting.

Carefully check the valve rating considering all the factors

affecting its capacity. See Bulletin 10-9, or Bulletin 10-10.

Remedy

— Replace valve with one correctly sized. On

multiple circuit evaporators using a refrigerant distributor, the

capacity of the valve can be reduced, within certain limits, by

installing a smaller distributor nozzle. See Bulletin 20-10.

3. Bulb location

— If the bulb is located in a suction line trap,

its temperature will be affected by liquid oil and refrigerant

alternately collecting and evaporating at this point. This

condition frequently results in severe hunting.

Remedy

— As a temporary measure relocate the bulb away

from the trap, and any turbulent areas created by elbows, tees,

etc. Also remove the bulb from the air stream or insulate. Re-

pipe if necessary. Sometimes another position around the

circumference of the suction line will minimize hunting. Follow

the Bulb Location and Installation instructions given on Page 2

for the best TEV control.

4. Refrigerant and load distribution

— In addition to the

effects of poor distribution explained in paragraphs

D-1

and

D-

2

, hunting also frequently results. This is caused by liquid

refrigerant from the overfed circuits occasionally reaching the

bulb of the valve.

Remedy

— Correct the faulty distribution.

5. Superheat adjustment

— All Sporlan TEVs are preset at

the factory to give the best performance on the average system.

A valve should not be adjusted unnecessarily, but occasionally

another setting may prove to be better.

Remedy

— Turn the adjusting stem clockwise a turn at a time.

If the hunting stops or is reduced, turn the adjusting stem

counter clockwise a turn at a time to obtain the lowest superheat

with stable operation.

6. Moisture

— As ice forms in a TEV from excessive moisture,

a very erratic hunt may result.

Remedy

— Remove the moisture with the installation of a

Sporlan Catch-All Filter-Drier. A safe moisture level can be

determined by installing a Sporlan See•All.

Complaint "F"

“System won't perform properly.”

SYMPTOM:

■

Cannot get valve to react or regulate at all.

THE CAUSE MAY BE:

1. No refrigerant being fed to evaporator

. See Section

A

on Pages 6 & 7.

2. Too much refrigerant being fed to evaporator

. See

Section

B

on Page 8.

3. Too much refrigerant being fed to evaporator at

start-up only

. See Section

C

on Page 8.

4. Refrigerant control is erratic

. See Section

D

on Page 9.

5. System is hunting or cycling

. See Section

E

on Page 9.

6. The TEV has been physically abused in an effort

to make the valve work properly.

This is usually the

result of a mistaken analysis. It is frequently assumed that if a

valve does not feed properly, it is stuck (either opened or

closed). Beating the valve body with a hammer will only distort

the body and make it impossible for the valve to work once the

real cause is determined.

If a valve “sticks,” it is usually due to moisture freezing in the

port, dirt and other foreign material restricting or plugging the

internal parts, wax forming on the internal parts at low temper-

atures, or the valve has been physically abused so it

cannot

function.

Remedy

— Inspect the valve and its internal parts, including

the inlet strainer. If plugged or restricted in any way, clean the

parts thoroughly, oil the parts with a good grade of refrigerant

oil, and reassemble the parts. Complete details on this subject

are found on Pages 10 through 12.

If the valve is beyond normal cleaning processes, or if it is

physically damaged in any way, replace the valve with its proper

replacement model.

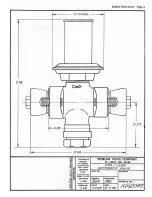

Field Assembly

Instructions

Sporlan valves my be opened easily for inspection.

Thermostatic

Element

Pushrods

Inlet

Body

Outlet

Seat

Pin Carrier

Spring

Spring Guide

Bottom Cap

Assembly

Seal Cap

Adjusting Stem

Figure 9

Summary of Contents for VSM 71-701

Page 1: ...1 VPN 35391S February 2006 Rev 05 Price 60 00...

Page 2: ...2...

Page 20: ...20...

Page 52: ...53 Pre Start Up Check List...

Page 99: ...99 Recommended Spare Parts List...

Page 104: ...104 Gate Rotor...

Page 110: ...110 Main Rotor VSS...

Page 112: ...112 Main Rotor VSR...

Page 114: ...114 Slide Valve Cross Shafts and End Plate...

Page 118: ...118 Capacity Slide Volume Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 134: ...134 Miscellaneous Frame Components VSS Screw Compressor VSR Mini Screw Compressor...

Page 138: ...138 C FlangeAdapter Components 630 620 610 640 601 641 630 601 620 610 640 641 642 650 651...

Page 140: ...140 Replacement Parts Tools...

Page 144: ...144 GaterotorAssembly...

Page 148: ...148 Main Rotor Slide Valve Cross Shafts and End Plate Models 71 401 Only Counter clockwise...

Page 152: ...152 Main Rotor Slide Valve Cross Shafts and End Plate Model 501 701 Only Clockwise...

Page 154: ...154 Volume Ratio Capacity Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 158: ...158 Miscellaneous Frame Components Model VSM 501 701 Model VSM 71 401...

Page 160: ...160 Replacement Parts Accessories Housing Accessories C Flange Assembly...

Page 166: ...166 Haight Pumps...

Page 170: ...3 Refrigerating Specialties Division...

Page 236: ......

Page 237: ......

Page 238: ......

Page 243: ......

Page 244: ...168...