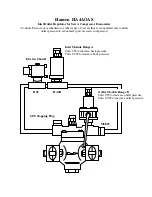

HA4AOAS - Inlet/Outlet Economizer Port / Side Load Pressure

Regulator

Purpose:

To maintain an operating pressure in the economizer or side load vessel, while providing a means

of protecting the compressor motor from overloading from high economizer loads during start-up, or from

high side loads.

Construction:

This valve is made up of an Outlet Pressure Regulator Base, an Inlet Pressure Regulator

Module, and a Shut Off Solenoid.

Operation:

The Shut Off Solenoid must be energized to activate the HA4AOAS valve. For a flash type or

shell & coil type economizer, or for side load applications, the solenoid must be activated when the

compressor starts. For a direct expansion type, the solenoid is generally activated when the compressor

reaches 30% to 70% compressor capacity, depending on the system.

Adjusting the Inlet / Economizer or Side Load Pressure

The estimated economizer operating pressure of the valve will be as shown on the performance printout for

the compressor unit. Side load pressure settings would be set as required for the system. By means of a

pressure gauge, the actual economizer operating pressure can be determined by placing the Inlet Pressure

Regulator module range spring at minimum force (control module stem should be fully turned counter-

clockwise). Leaving the regulator in this position, the actual economizer compressor port pressure can be

read. NOTE: The compressor must be at 100% capacity and at normal operating suction and discharge

pressures before the actual port pressure can be determined. Once this pressure is known, the module stem

should be turned clockwise until there is a slight increase in pressure shown on the gauge. Increasing the

turns on the module stem will raise the inlet pressure.

Adjusting the Outlet / Maximum Port Pressure

The Outlet Pressure setting is a maximum pressure setting that will allow the compressor to load to 100%.

If too much economizer or side port gas flow occurs, port pressure increases resulting in a motor amperage

increase, which may result in amp limiting and the compressor will not load to 100%. In order to adjust the

Outlet Pressure Module, its range spring should be set near maximum force (control module stem should be

fully turned clockwise). If the compressor is not able to fully load because of Amp limiting, the outlet

pressure needs to be decreased by turning the stem counter-clockwise until there is a decrease in pressure

shown on the gauge. Reduce outlet pressure until motor amperage drops and the compressor is able to load

to 100% capacity. Make sure that the Outlet Pressure setting is at least 10 psig higher than the inlet pressure

to prevent a conflict in operation of the inlet and outlet features of the valve. NOTE: There must be

abnormally high gas flow to set the outlet feature. It may not be necessary to use the outlet feature if the

compressor motor has been sized large enough so that the unit does not amp limit on high economizer or

side load gas flow.

Summary of Contents for VSM 71-701

Page 1: ...1 VPN 35391S February 2006 Rev 05 Price 60 00...

Page 2: ...2...

Page 20: ...20...

Page 52: ...53 Pre Start Up Check List...

Page 99: ...99 Recommended Spare Parts List...

Page 104: ...104 Gate Rotor...

Page 110: ...110 Main Rotor VSS...

Page 112: ...112 Main Rotor VSR...

Page 114: ...114 Slide Valve Cross Shafts and End Plate...

Page 118: ...118 Capacity Slide Volume Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 134: ...134 Miscellaneous Frame Components VSS Screw Compressor VSR Mini Screw Compressor...

Page 138: ...138 C FlangeAdapter Components 630 620 610 640 601 641 630 601 620 610 640 641 642 650 651...

Page 140: ...140 Replacement Parts Tools...

Page 144: ...144 GaterotorAssembly...

Page 148: ...148 Main Rotor Slide Valve Cross Shafts and End Plate Models 71 401 Only Counter clockwise...

Page 152: ...152 Main Rotor Slide Valve Cross Shafts and End Plate Model 501 701 Only Clockwise...

Page 154: ...154 Volume Ratio Capacity Slide Carriage Assembly Slide Valve Carriage Assembly...

Page 158: ...158 Miscellaneous Frame Components Model VSM 501 701 Model VSM 71 401...

Page 160: ...160 Replacement Parts Accessories Housing Accessories C Flange Assembly...

Page 166: ...166 Haight Pumps...

Page 170: ...3 Refrigerating Specialties Division...

Page 236: ......

Page 237: ......

Page 238: ......

Page 243: ......

Page 244: ...168...