- 16 -

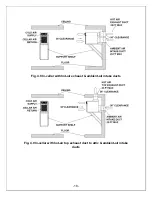

3. Through-wall installation with hot-air exhaust and ambient-air intake

ducts (Fig. 4.6 & 4.7)

It is the installation when the cooling unit can not exhaust the hot air to an

adjacent space.

1) The cooling unit shall be mounted near the ceiling with equal distance from

each side of the cellar.

2) Cut a rectangular opening between two wall studs. The dimensions of the

opening shall be 1/4” larger than the width and height of the cooling unit.

3) Construct a shelf as shown. The shelf must be capable of supporting the

weight of the cooling unit and preventing it from moving.

4) Place the cooling unit on the shelf with the back of the unit flush with the

outside of the wall.

5) Seal the clearance between the cooling unit and opening with a high quality

weather stripping, polyurethane spray foam, or foam tape. Cover the seal with

molding and attach the molding to the wall not the unit.

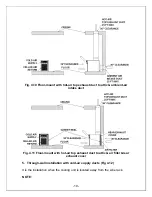

6) Attach the duct hoods to the rear of the cooling unit with screws (Use #8 x ½L

screws only).

7) Attach the insulated ducts to the hoods with adhesive tapes.

8) Secure the ducts with conduits to the cellar exterior walls and make sure they

are not curled, twisted, bent and clogged.

9) Install an air filter at the rear of the cooling unit.

10)

Plug the unit into a properly grounded and dedicated outlet of adequate

capacity.

11) Turn on the high condenser fan switch.

12)

Turn the evaporator fan control knob clockwise to the lowest speed position.

NOTE:

•

The exhaust and intake ducts can be combined maximum 50 ft long.

•

The cooling unit can also be installed with its front flush with the racks

or the inside of the wall. Insulate any cold surfaces of cooling unit for

better performance if exposed to the outside.

Summary of Contents for Wine-Mate WM-4510HZD

Page 24: ...23 Fig 4 15 Cold air supply cellar air return and hot air exhaust ducts...

Page 29: ...28 Electrical Wiring Diagrams Fig 7 1 WM 4510 8510HZD standard wiring diagram...

Page 30: ...29 Fig 7 2 WM 4510 8510HZD crankcase heater wiring diagram...

Page 31: ...30 Fig 7 3 WM 4510 8510HZD alarm call wiring diagram...

Page 32: ...31 Fig 7 4 WM 4510 8510HZD cellar heater wiring diagram...

Page 33: ...32 Fig 7 5 WM 4510 8510HZD crankcase heater alarm call wiring diagram...

Page 34: ...33 Fig 7 6 WM 4510 8510HZD crankcase heater cellar heater wiring diagram...

Page 35: ...34 Fig 7 7 WM 4510 8510HZD alarm call cellar heater wiring diagram...

Page 36: ...35 Fig 7 8 WM 4510 8510HZD crankcase heater alarm call cellar heater wiring diagram...