- 20 -

Care Guide

1. Cleaning Condenser

•

Clean the condenser regularly at least every 6 months.

•

Condenser is located on the ambient air intake side of the cooling unit.

•

Use a condenser brush or a vacuum cleaner with an extended attachment to

clean the condenser.

2. Removing Condensate

Remove the excessive condensate if it is accumulated on the cooling unit in high

humidity conditions.

3. Removing Unit

When you remove the cooling unit, beware water may come out of the unit.

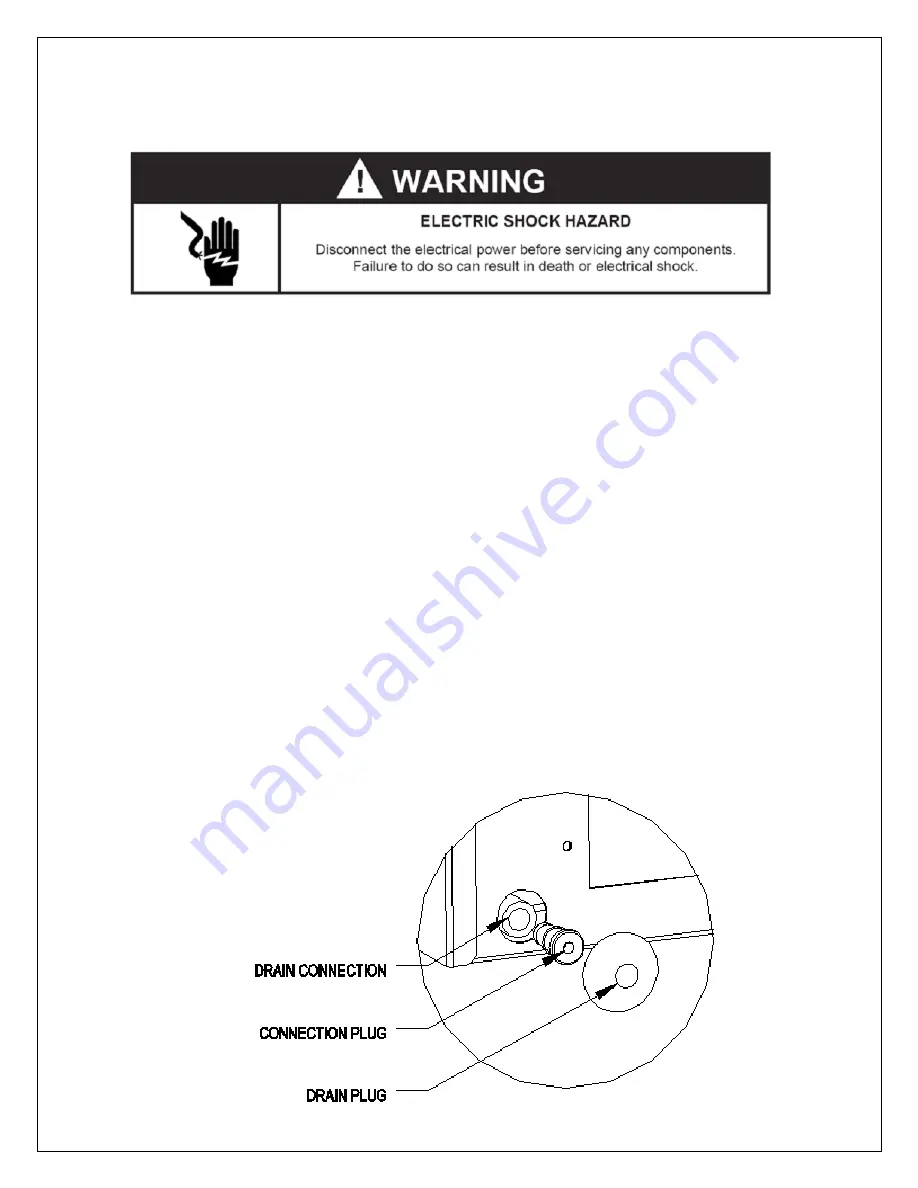

4. Installing Drain Line

WM-3520~8520HZD units are equipped with an additional drain fitting. In case of

extreme humidity there is a drain line needed, remove the drain plug on the

bottom left at the rear, then remove the connection plug and fit a 0.375” OD drain

tube into the drain connection. Install the cooling unit with the front higher than

the rear.

Summary of Contents for WM-1520HZD

Page 5: ... 4 Fig 1 2 WM 3520 8520HZD FEATURE DESCRIPTIONS Fig 1 3 WM 1520 2520HZD DIMENSIONS ...

Page 9: ... 8 Fig 2 2 THREAD INSERT Fig 2 3 REAR GASKET ...

Page 10: ... 9 Fig 2 4 TOP EXHAUST GASKET Fig 2 5 COOLING UNIT MOUNTING ...

Page 11: ... 10 Fig 2 6 SECURING BRACKET SCREW ...

Page 12: ... 11 Fig 2 7 CABINET GRILLE ...

Page 26: ... 25 Fig 6 3 WM 3520 8520HZD WIRING DIAGRAM Fig 6 4 WM 3520 8520HZD WIRING DIAGRAM ALARM CALL ...