Bellavista

Italian Prestige Rigid Turntable

Troubleshooting

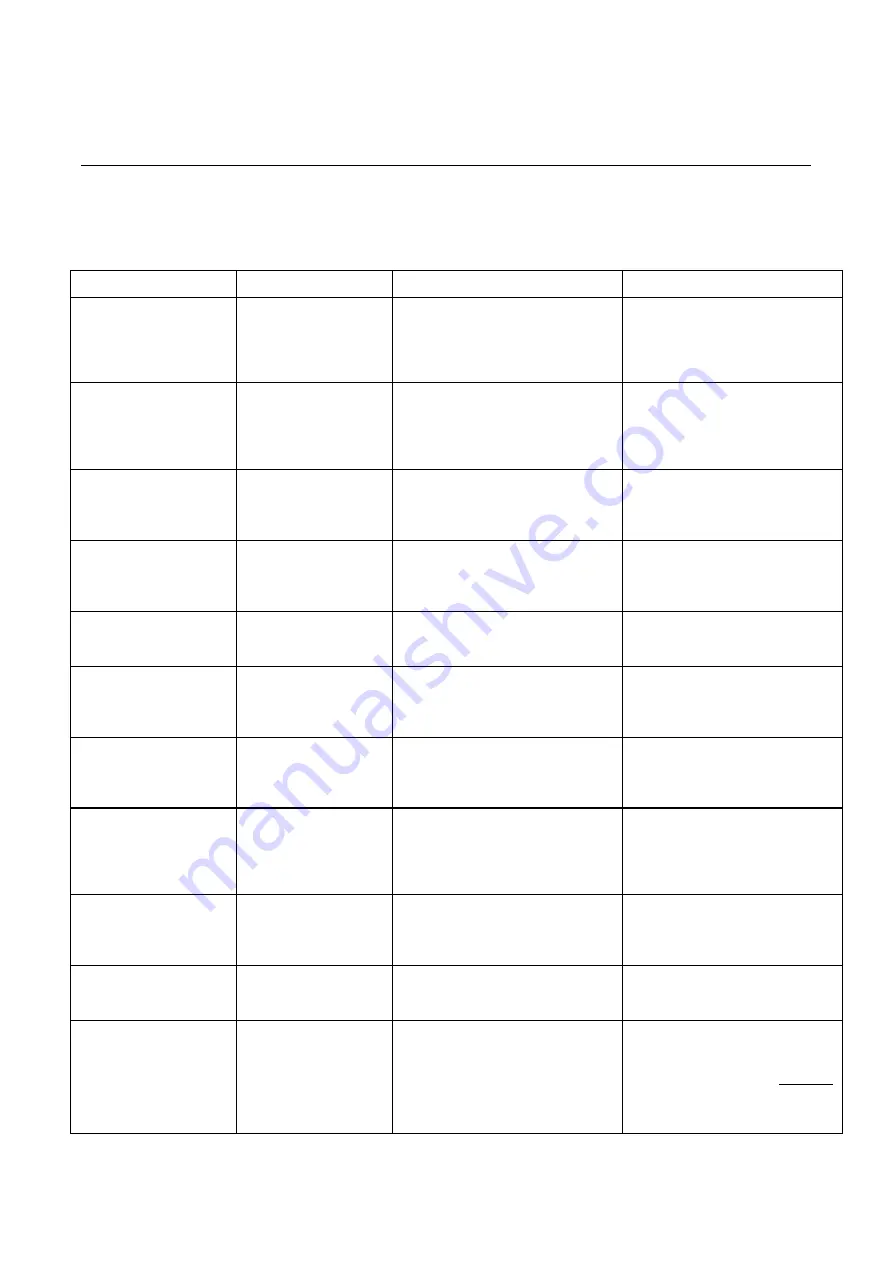

SYNPTOM

DESCRIPTION

CAUSE

REMEDY

BELT NOISE DURING

PLAY (GREEN BELT)

The Green Belt makes a

noise during playing

•

Because its low elasticity and

the presence of ceramic particles the

characteristics of the green belt make it

noisier than usual rubber black belts; It

does not affect the sound

•

If a quieter belt is requested

ask your local dealer for one of the

newest Bluenote Black Rubber Belts

BELT WOBBLING DURING

PLAY (GREEN BELT)

The Green Belt wobbles

during playing

•

Because its low elasticity and

the presence of ceramic particles the

characteristics of the green belt make it

wobbles a little around the motor pulley;

It does not affect the sound

•

If a not wobbling belt is

requested ask your local dealer of the

newest Bluenote Black Rubber Belts

GROOVE JUMPING

The phono cartridge

jumps during listening

sessions

•

The turntable is a rigid unit

and need to be insulated by vibrations

including footfall problems you have, in

example, a shaking floor.

•

Insulate the turntable with air

suspend devices or use a WALLSHELF

as turntable board support.

MOTOR HEATING

The Motor warms up too

much

•

AC synchronous motors as

the ones used by Bluenote normally

warms up to 50° Celsius without creating

any problem

MOTOR NOISE

The Motor produces a low

scraping noise during

playing

•

The pulley’s shaft slightly

touches the motor gold plated cover

•

Gently lift it up a bit

unscrewing the hex bolt of the pulley

The Motor produces a

scraping noise during

playing

•

Your turntable has a serial

number before the 11650

•

Ask your local dealer to

change the internal capacitor filters the

AC voltage and add the newer Teflon®

washer at the motor spindle bottom

The Motor produces a buzz

noise during playing

•

T h e 3 stainless steel screws of

the gold plated motor cover are too

tighten

•

Unscrew them enough to let

the motor spins without making noise,

they need just to be very gently screwed

to the motor cover

OIL POORED FROM

BRONZE BEARING

Oil drops come out the

botto m Platter Bearing

when the Platter Spindle is

inserted

•

The super high pressure created

by the strict tolerance of the

Bearing/Spindle system can let some oil

drops come out from the bottom of the

Platter Bearing

•

Clean it up, the oil will never

comes out again once the Platter

spindle is perfectly positioned into the

Platter Bearing

PLATTER BENT

The Platter looks bent on

the Turntable board

•

Clamp the Spindle tip into the

above side of the platter screwing it

strongly using a metal pin to get into the

tip hole

•

•

The Turntable Platter Bearing

Bolt is 10mm thick having a serial

number before the 11500

•

Ask your dealer to have the

new thicker Turntable Platter Bearing

Bolt

PULLEY WOBBLING

The aluminium adjustable

Pulley evidently wobbles

during turntable play

mode

•

•

With the Allen key supplied

adjust the 2 hex bolts fix the pulley on

the motor spindle until you find the

perfect on axis spinning – a PERFECT

on axis spinning must be found with a

bit of practice eventually marking up

one of the 2 hex bolts to know which