Manual VIPA HMI

Chapter 2

Deployment Touch Panel

HB160E - TP - RE_605-3B1F0 - Rev. 10/16

2-3

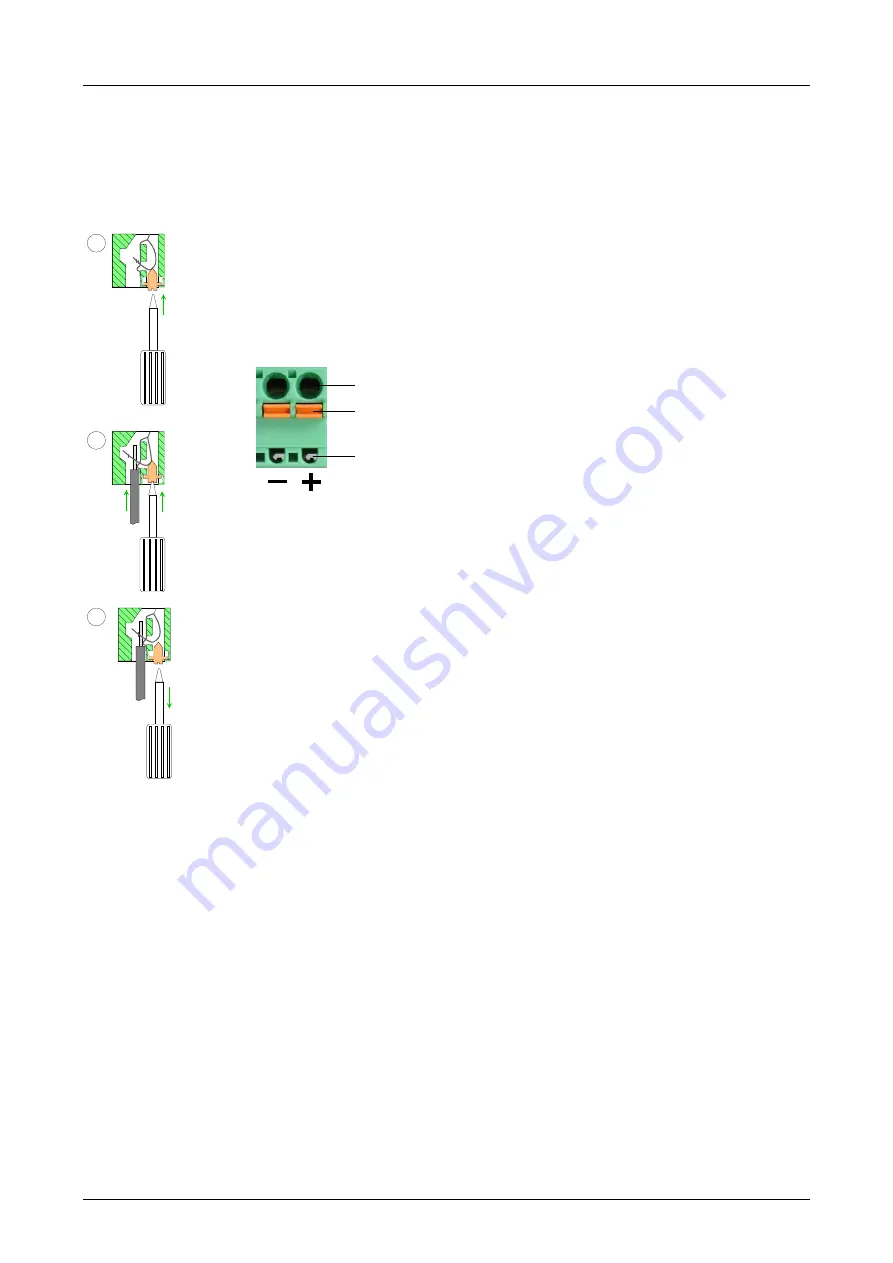

For the cabling of the DC 24V power supply green plugs with CageClamp

technology are deployed. The spring-clip connector technology simplifies

the wiring requirements for signaling and power cables. In contrast to

screw terminal connections, spring-clip wiring is vibration proof.

Here also you may connect wires with a cross-section of 0.08mm

2

to

2.5mm

2

. You can use flexible wires without end case as well as stiff wires.

You fix the conductors to the CageClamps like this:

DC 24V

1

2

3

[1]

Round opening for wires

[2]

Locking (orange) for screwdriver

[3]

Test point for 2mm test tip

1

2

3

The picture on the left side shows the cabling step by step from top view.

•

For cabling you push the locking vertical to the inside with a suiting

screwdriver and hold the screwdriver in this position.

•

Insert the insulation-striped wire into the round opening. You may use

wires with a cross-section from 0.08mm

2

to 2.5mm

2

.

•

By removing the screwdriver the wire is connected safely with the plug

connector via a spring.

Connect

power supply

Summary of Contents for 605-3B1F0

Page 1: ...VIPA HMI Touch Panel 605 3B1F0 Manual HB160E_TP RE_605 3B1F0 Rev 10 16 April 2010...

Page 4: ...Contents Manual VIPA System HMI ii HB160E TP RE_605 3B1F0 Rev 10 16...

Page 8: ...Safety information Manual VIPA System HMI 4 HB160E TP RE_605 3B1F0 Rev 10 16...

Page 20: ...Chapter 1 Hardware description Manual VIPA HMI 1 12 HB160E TP RE_605 3B1F0 Rev 10 16...

Page 52: ...Chapter 2 Deployment Touch Panel Manual VIPA HMI 2 32 HB160E TP RE_605 3B1F0 Rev 10 16...

Page 66: ...Index Manual VIPA System HMI A 2 HB160E TP RE_605 3B1F0 Rev 10 16 M Stich...