Chapter 3 Installation Guidelines

Manual VIPA HMI

3-12

HB160E - TP - RE_62F-FCB0

- Rev. 11/14

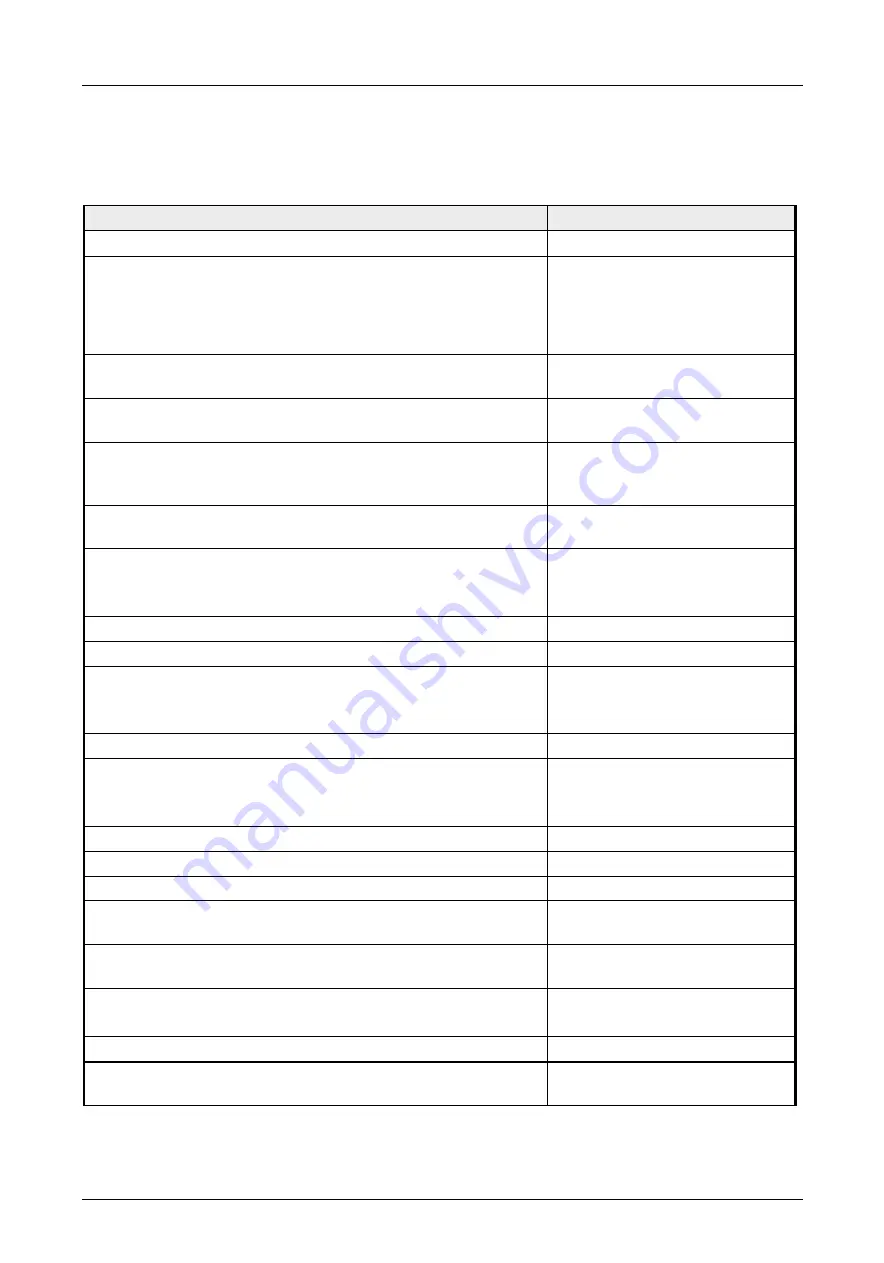

Checklist for the EMC-compliant installation of controllers

EMV-measures

Space for Notes

Connection of the inactive parts

You should take special care to check the connections of:

•

Module racks

•

Frames

•

Screen and protected earth conductor

Are all the inactive metal parts interconnected by means of

large-surface and low-impedance connections?

Has a proper connection been installed with respect to the

ground/protected earth conductor system?

Has the isolation been removed from varnished and anodized

surfaces or have these connections been fitted with special

contact washer?

Have the connection been protected from corrosion, e.g. by

means of grease?

Have doors been grounded by means of grounding straps

connected to the body of the cubicle?

Cable routing

Cabling divided into groups?

Power cables (230 ... 400V) and signal lines installed in

separate channels or bunches?

Potential compensating

When installing the equipment at separate locations, check

the installation of the potential compensating line.

Cable screen

All covers of plugs are metallic?

All analog and data lines installed screened?

Line screens attached to the screening or the protected earth

conductor?

Have the screens been connected by means of large-surface

and low-impedance cable clamps?

Cable screens grounded both-sided where possible?

Inductors

Have the coils of contactors controlled by means of contacts

been connected to snubber networks?

All manuals and user guides at all-guides.com