PREVENTITIVE MAINTENANCE

: Before performing any maintenance

on the machine, be sure that the power is

turned off, or the batteries disconnected.

: Repairs are to be completed by an

authorized Viper service center only. Any

repairs completed by unauthorized persons will

void the warranty.

DAILY MAINTENANCE

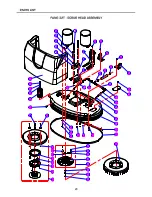

1. Remove pad driver / brush and clean with

approved cleaner.

2.

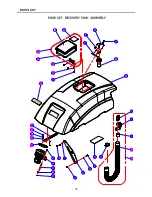

Drain recovery and solution tanks completely

and rinse out with clean water. Visually check

the recovery tank for debris and clean out as

necessary.

3.

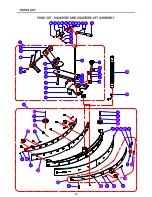

Raise squeegee assembly off the floor and

wipe it down with a damp towel. Be sure to

store the squeegee in the up position.

4.

Remove the float shut-off assembly and rinse

it out with clean water.

5.

Clean machine with an approved cleaner and a

damp towel.

6.

Recharge batteries.

WEEKLY MAINTENANCE

1.

Check fluid level in batteries.

2.

Check batteries for loose or corroded cables.

3.

Keep battery tops clean from corrosion.

MONTHLY MAINTENANCE

1.

Check machine for leaks and lose fasteners.

2.

Lubricate all grease points and pivot points

with silicon spray and approved grease.

3.

Place machine over a floor drain. Flush

solution system by pouring 3 gallons of hot

water and approved alkaline detergent into the

solution tank and running machine (with

solution control on) for 45 seconds. Turn

machine off and let it sit over-night. The

following day, drain the remaining solution

and rinse the solution tank out with clean

water.

VACUUM MOTOR MAINTENANCE

1.

Contact your local Viper Distributor for any

motor maintenance.

2.

Vacuum motor should have the brushes

checked every 250 hours. Brushes should be

replaced when they are worn to a length of

10mm or less.

BATTERY MAINTENANCE

: For the best machine performance,

keep batteries charged at all times. Do not let

them sit in a discharged condition.

: Batteries are dangerous! Batteries

emit hydrogen gas and an explosion or fire can

result. Keep sparks and fire away from

batteries at all time.

: Whenever servicing batteries, be

sure to wear protective gloves. Avoid contact

with battery acid at all times!

1.

Always follow the battery charging directions

as outlined in the BATTERY CHARGING

section of this manual.

9