Basic MIG Welding

Good weld quality and weld profile depends on gun angle, direction of travel, electrode extension (stick out), travel speed, thickness of base

metal, wire feed speed (amperage) and arc voltage. To follow are some basic guides to assist with your setup.

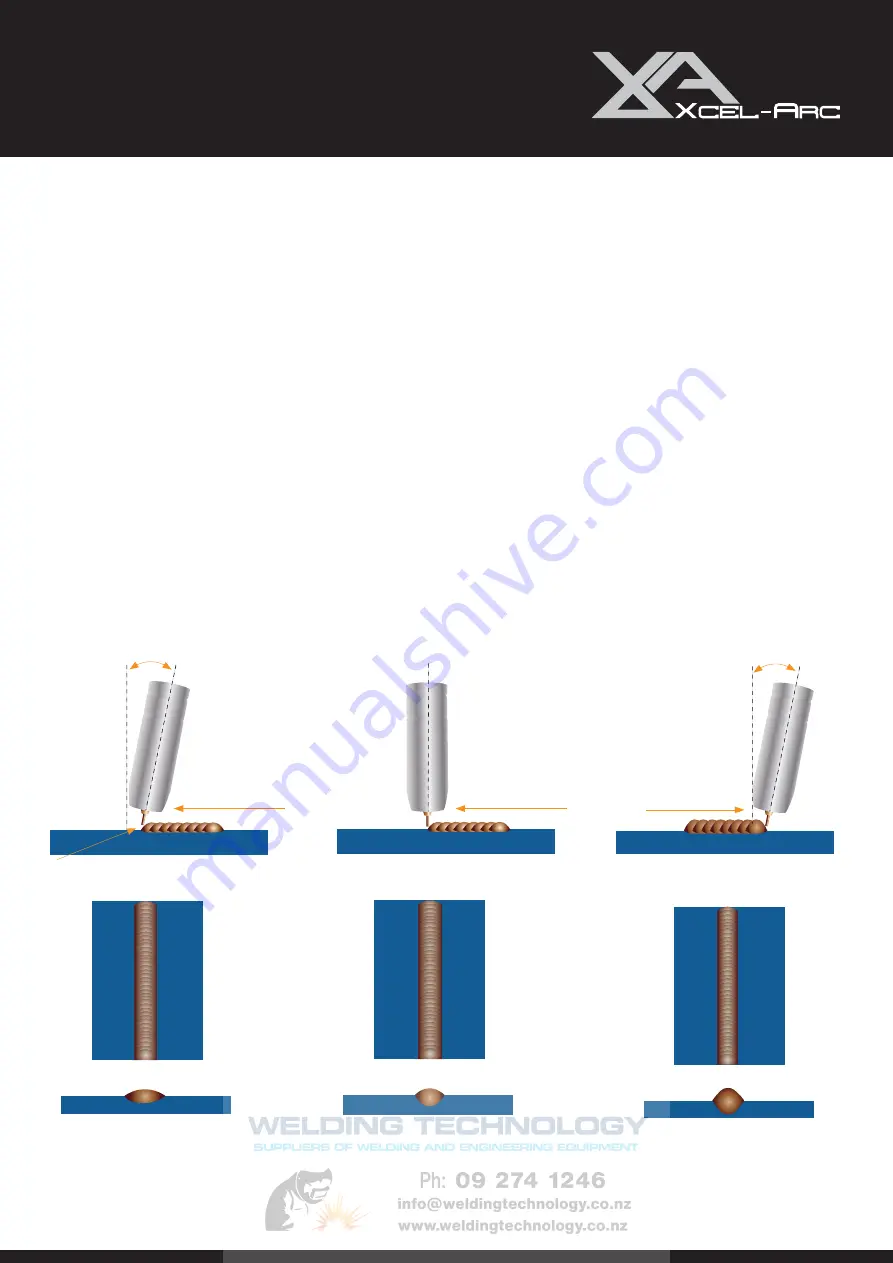

Gun Position - Travel Direction, Work Angle

Gun position or technique usually refers to how the wire is directed at the base metal, the angle and travel direction chosen. Travel speed and work angle

will determine the characteristic of the weld bead profile and degree of weld penetration.

Push Technique

The wire is located at the leading edge of the weld pool and pushed towards the un-melted work surface. This technique offers a better view of the weld

joint and direction of the wire into the weld joint. Push technique directs the heat away from the weld puddle allowing faster travel speeds providing a

flatter weld profile with light penetration - useful for welding thin materials. The welds are wider and flatter allowing for minimal clean up / grinding time.

Perpendicular Technique

The wire is fed directly into the weld, this technique is used primarily for automated situations or when conditions make it necessary. The weld profile is

generally higher and a deeper penetration is achieved.

Drag Technique

The gun and wire is dragged away from the weld bead. The arc and heat is concentrated on the weld pool, the base metal receives more heat, deeper

melting, more penetration and the weld profile is higher with more build up.

10

°

Wire pointed ahead of bead

Wire pointed back into bead

Travel direction

Travel direction

Travel direction

(A) Push Technique

(B) Gun Perpendicular

(C) Drag Technique

10

°

Flat even weld profile light

penetration

Narrower weld profile

even penetration

Narrow higher weld profile

more penetration

16

| VIPER 120 SYNERGIC MIG Welder Manual

MIG WELDING GUIDE