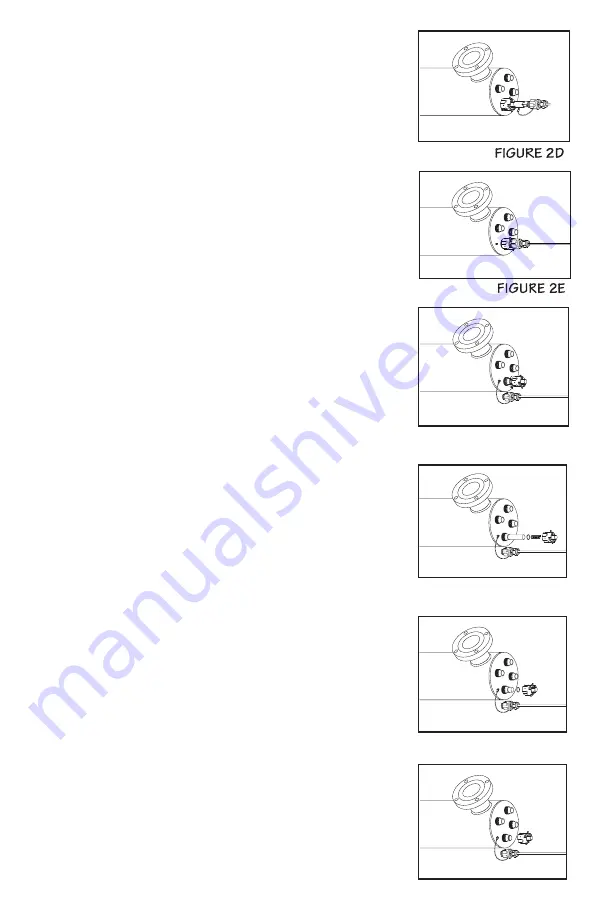

is fully seated onto the UV lamp (Figure 2D).

4. Once the lamp is fully seated on the connector, slide the

connector up to the retaining nut. Once the connector is

located fully against the retaining nut, slide the metal ring back

in to lock the connector in place (Figure 2E). As this connector

is keyed to the reactor chamber, make sure the notch on the

connector (Figure 2D) is located over the ground lug located on

the reactor chamber.

Quartz Sleeve Replacement / Cleaning:

Mineral deposits and sediment may accumulate on the quartz sleeves

decreasing the UV energy detected. Good maintenance of filtration

equipment will reduce the accumulation of residues. If necessary,

remove the quartz sleeves and clean with a commercially available

scale remover (CLR, Lime-Away, etc.) and a lint free cloth. Repeat

the process as often as necessary to keep the quartz sleeves clean.

Be sure to remove all traces of cleaning fluid from the sleeve before

it is reinstalled in the reactor (be sure not to allow liquid inside the

sleeves).

1. Shut off the upstream water supply that feeds water into the

reactor chamber.

2. Open a downstream faucet to release any pressure that may be

built-up in the system.

3. Remove the UV lamps by following steps 1 & 2 as outlined in the

“Lamp Replacement” section on page

8.

4. Remove the retaining nuts by turning counter clockwise (Figure

3a). Drain chamber through drain port. Grasp the quartz sleeve

and fully remove from the reactor chamber. Remove both o-rings.

As with the lamp, make sure the sleeves are removed from the

reactor chamber being careful not to angle the sleeve as they are

removed from the reactor (Figure 3b) to avoid breakage. Make sure

not to let the sleeve fall inside the chamber after the sleeve end

passes the threaded port.

5. Clean the sleeve as outlined in above, or replace with a new

sleeve. Reinstall the quartz sleeve in the reverse order. To install

the sleeves, carefully insert the sleeves into the reactor chamber

(do not drop) and push the sleeves (Figure 3c), to the opposite

end of the chamber making sure the sleeves are inserted into the

corresponding holes on the opposite end of the chamber. Install a

wetted o-ring (Part number 410867) onto both ends of the sleeves

until they are positioned against the chamfered seat (Figure 3d).

6. Reinstall the retaining nut on the reactor chamber and tighten by

turning clockwise. The retaining nuts should be hand- tightened

only, the use of a wrench is not required, nor recommended.

Reinstall the connector as outlined in step four of the “Lamp

Replacement” section.

7. Slowly turn on water and pressurize the reactor to verify that there

are no leaks.

8. Reconnect to power source and follow the Controller start-up

sequence to make sure the system is operating properly.

FIGURE 3A

FIGURE 3B

FIGURE 3C

9

FIGURE 3D