21

Threading a tube

The machine is supplied as standard with a die head for threading tubes with diameters from 1/2” to 2”.

Optionally available is a head for threading tubes of 1/4” to 3/8” diameter (part no. 162150).

Producing a thread

Install the appropriate head for the tube diameter (see pages 25 and 28 for the procedures

for installing 2” and 1/4 – 3/8” heads).

Position the tube as indicated on page 18.

Important:

Position the tube such that the end to be threaded is

well to the right of the red

line

on the front post of the saddle:

The saddle must not go past this limit:

doing this will tear the thread and could even

cause the tube to crack.

Thread: Select position R (R for Right).

Position L ( L for Left) is used to have the motor rotating leftwise.

To switch direction of rotation à l’autre, it is imperative to hold the switch on the 0 position as

long as the motor has not stopped.

Start the motor. Rotation to the right (R).

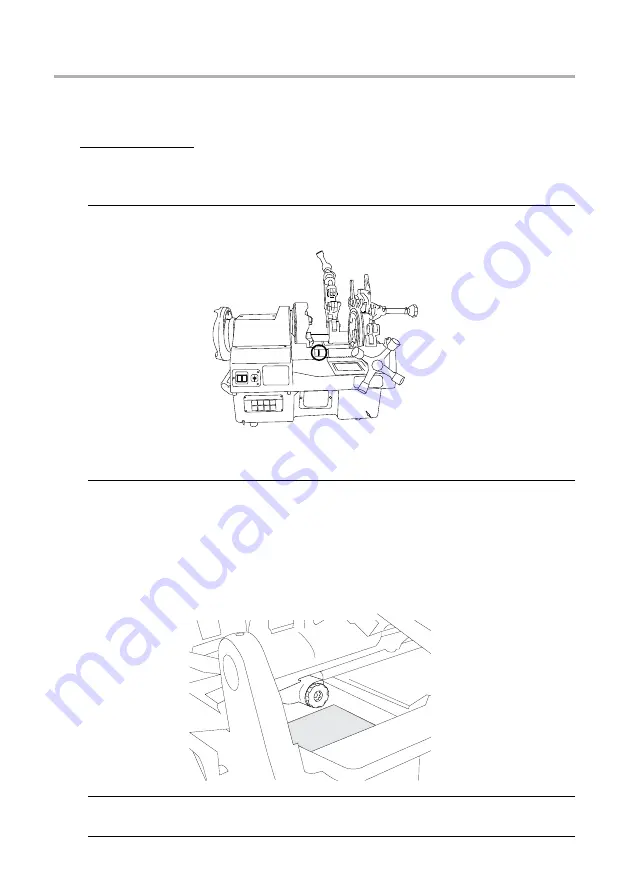

Adjust the oil flow so as to obtain sufficient lubrication and no excess oil. The oil flow regulating

wheel is located on the rear panel, right hand side, of the machine:

Important:

Never cut a thread on a tube without a sufficient oil flow. You risk damaging the

tube, the die and the machine.

●

●

●

●

●

●

●

EN

Summary of Contents for 162120

Page 1: ...Threading machine for tubes up to 2 Instruction Manual 162120 EN ...

Page 3: ...EN ...

Page 51: ...49 Exploded view of the motor and the oil pump Pump EN ...

Page 52: ...50 Exploded view of the transmission EN ...

Page 53: ...51 Exploded view of the saddle EN ...

Page 54: ...52 Exploded view of the automatic opening 2 die head EN ...

Page 55: ...53 Exploded view of the 1 4 3 8 die head EN ...

Page 56: ...54 Exploded view of the tube cutter EN ...

Page 58: ...56 Components of a nipple holder EN ...

Page 59: ...EN ...