22

By turning the handwheel

to the right

, move the saddle forward so that the dies come into

contact with the tube end.

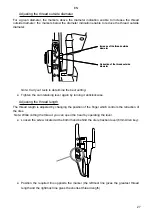

Note: A plate on the frame gives a reminder that the saddle moves in the opposite direction

to the direction of rotation of the wheel: the saddle moves to the left (i.e. towards the front

chuck) when you turn the wheel to the right, and vice versa.

!

Turn the wheel slowly to the right applying pressure to enable the die to cut into the tube

end.

When the die has cut 3 or 4 threads, release the wheel and let the saddle move by itself. (You

should not accompany the movement of the saddle as this risks making the thread

inaccurate).

When the preset length of the thread is reached, the dies will retract automatically. (The

operator has to manually open the 1/4” – 3/8” die head).

Stop the motor.

Check that the length of the thread and the outside diameter are sufficient: if a threaded collar

or joint is screwed onto the tube, part of the thread must still be visible. Loosen the chucks

and remove the tube.

Important:

If a thread turns out to be too short, change the length setting and carry out the threading

operation again from the start

and not from the end of the previous thread. (The joint may seize

where the two threads meet).

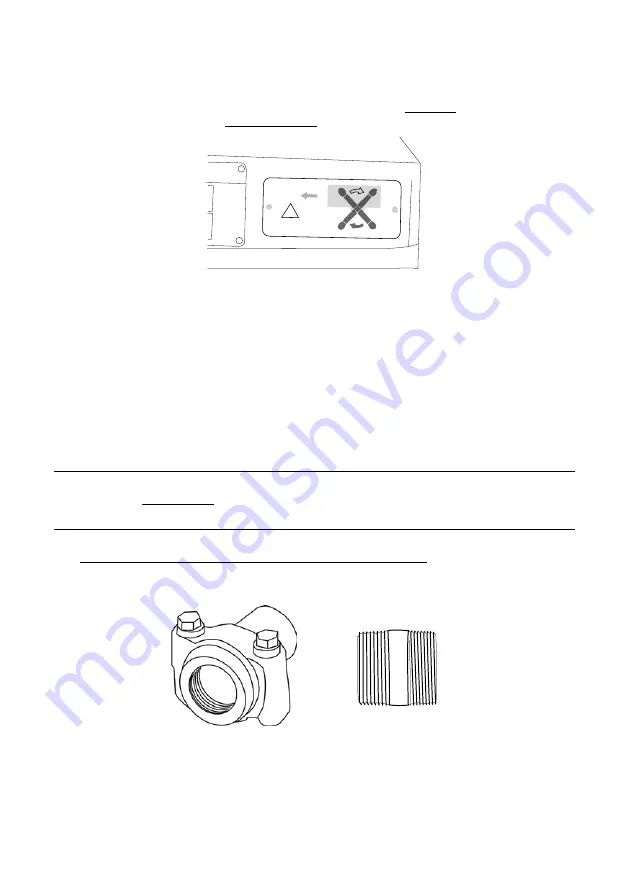

Producing double threads on short tubes (nipples or reels)

Virax supplies an optional nipple holder which can be used to produce double threads on short

tubes with diameters from 1/2” to 2”:

●

●

●

●

●

●

EN

Summary of Contents for 162120

Page 1: ...Threading machine for tubes up to 2 Instruction Manual 162120 EN ...

Page 3: ...EN ...

Page 51: ...49 Exploded view of the motor and the oil pump Pump EN ...

Page 52: ...50 Exploded view of the transmission EN ...

Page 53: ...51 Exploded view of the saddle EN ...

Page 54: ...52 Exploded view of the automatic opening 2 die head EN ...

Page 55: ...53 Exploded view of the 1 4 3 8 die head EN ...

Page 56: ...54 Exploded view of the tube cutter EN ...

Page 58: ...56 Components of a nipple holder EN ...

Page 59: ...EN ...