46

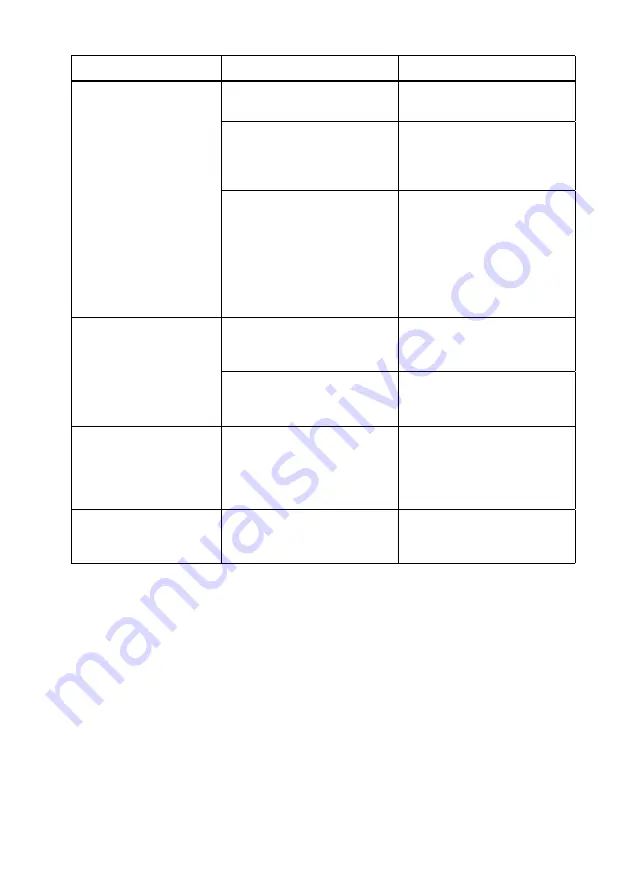

Problem

Possible causes

Corrective actions

The dies do not enter the

tubes sufficiently.

The dies are fouled.

Clean the ends of the dies with

a metal brush.

The dies are worn.

Replace the four dies by new

ones. (See page 30 for the 2”

head, and page 2 for the 1/4 –

3/8” head).

The die numbering has not

been complied with.

Remove the dies and replace

them (see page 0 for the 2”

head, and page 2 for the 1/4 –

/8” head) and ensure the

numbering of the dies is

complied with: die no.1 in

socket no. 1, die no.2 in socket

no.2, etc.

The quality of the thread

obtained is not

satisfactory.

Same reasons as above: dies

fouled or worn, or die

numbering not complied with.

See above.

Oil worn out

Drain the oil (see page 5) and

refill with oil supplied by Virax

(see page 9).

The thread is not deep

enough or is too deep.

The outside diameter of the

thread has not been set

correctly.

Adjust the thread diameter so

as to obtain the expected result.

(See page 27 for the 2” head,

and page 29 for the 1/4 – /8”

head).

With the 2” head, the

thread is too long or too

short

The thread length has not been

set correctly.

Adjust the thread length so as

to obtain the expected result.

(See page 27).

EN

Summary of Contents for 162120

Page 1: ...Threading machine for tubes up to 2 Instruction Manual 162120 EN ...

Page 3: ...EN ...

Page 51: ...49 Exploded view of the motor and the oil pump Pump EN ...

Page 52: ...50 Exploded view of the transmission EN ...

Page 53: ...51 Exploded view of the saddle EN ...

Page 54: ...52 Exploded view of the automatic opening 2 die head EN ...

Page 55: ...53 Exploded view of the 1 4 3 8 die head EN ...

Page 56: ...54 Exploded view of the tube cutter EN ...

Page 58: ...56 Components of a nipple holder EN ...

Page 59: ...EN ...