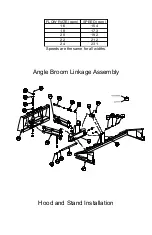

Features of Virnig Mfg. Inc. Angle Broom include:

Centering swing linkage better centers broom in front of loader when

angled.

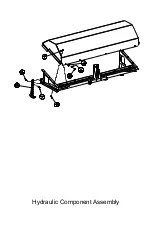

Optional Hydraulic Angle with Electric Control utilizes either the

machines electrical package or an add-on control box.

15-25 gpm operating flow rate range and 2000

– 3500 psi operating

pressure range.

Easy exchange of wafers, do not have to disconnect hydraulic lines to

change wafer sections.

Hydraulic pressure relief valves on the motor provide hydraulic

protection in both directions.

Direct drive design with replaceable drive components.

160° standard hood, optional deflector provides an additional 30° of

coverage and can be “uninstalled” by simply locking in the storage

position without removing.

Recommended for loaders with an operating capacity greater than 1500

lb.

Initial Use

Read and understand all warning information in this manual before

operating this attachment.

Check that quick-tach on frame fits onto loader properly. Pins must

engage through 3/8” plates at bottom of quick-tach.

Slowly roll back attachment. Make sure there is no interference

between attachment and loader.

Do not connect this attachment to high flow hydraulics.

Make sure hoses do not pinch during roll back.

Never exceed the maximum attachment operating pressure of 3500 psi.

After Angle Broom is mounted to the loader, lift or roll back the Angle

Broom so the storage stands are not contacting the ground. Flip

storage stands into

“storage” position before operation of the Angle

Broom.

With the Angle Broom off of the ground, engage the auxiliary hydraulics

using the “detent” position on the machine. Check the rotation of the

broom (broom should be sweeping away from the machine.) If this

rotation does not match the “detent” position of your machine, switch the

couplers on the lead hoses.

If Angle Broom is equipped with manual angle, swing the broom head

through its cycle to check that the lead hoses do not bind or catch