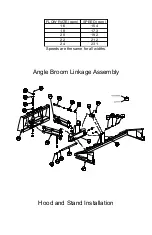

ITEM PART NO. QTY DESCRIPTION

C

1

1075PP

-

3/8" LOCK WASHER

2

6863PP

2

7/16" X 1-3/4" LG LYNCH PIN

C

3

7849PP

-

3/8"-16 X 1" LG HHCS

C

4

------

1

ANGLE BROOM DEFLECTOR WDT

C - See Table 2.

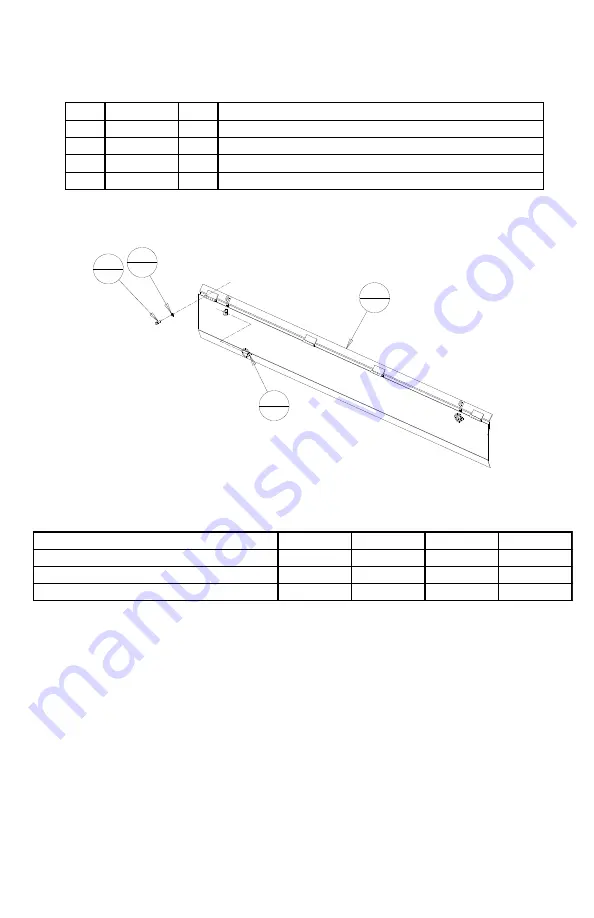

Table 2

MODEL

ABDF60

ABDF72

ABDF84

ABDF96

ANGLE BROOM DEFLECTOR WDT

8582VW

8596VW

8520VW

8600VW

HARDWARE QUANTITY

6

7

8

9

WEIGHT (lb)

35

40

50

55

1

-

2

2

3

-

4

1