need to change any part involved in this circuit, proceed as

follows:

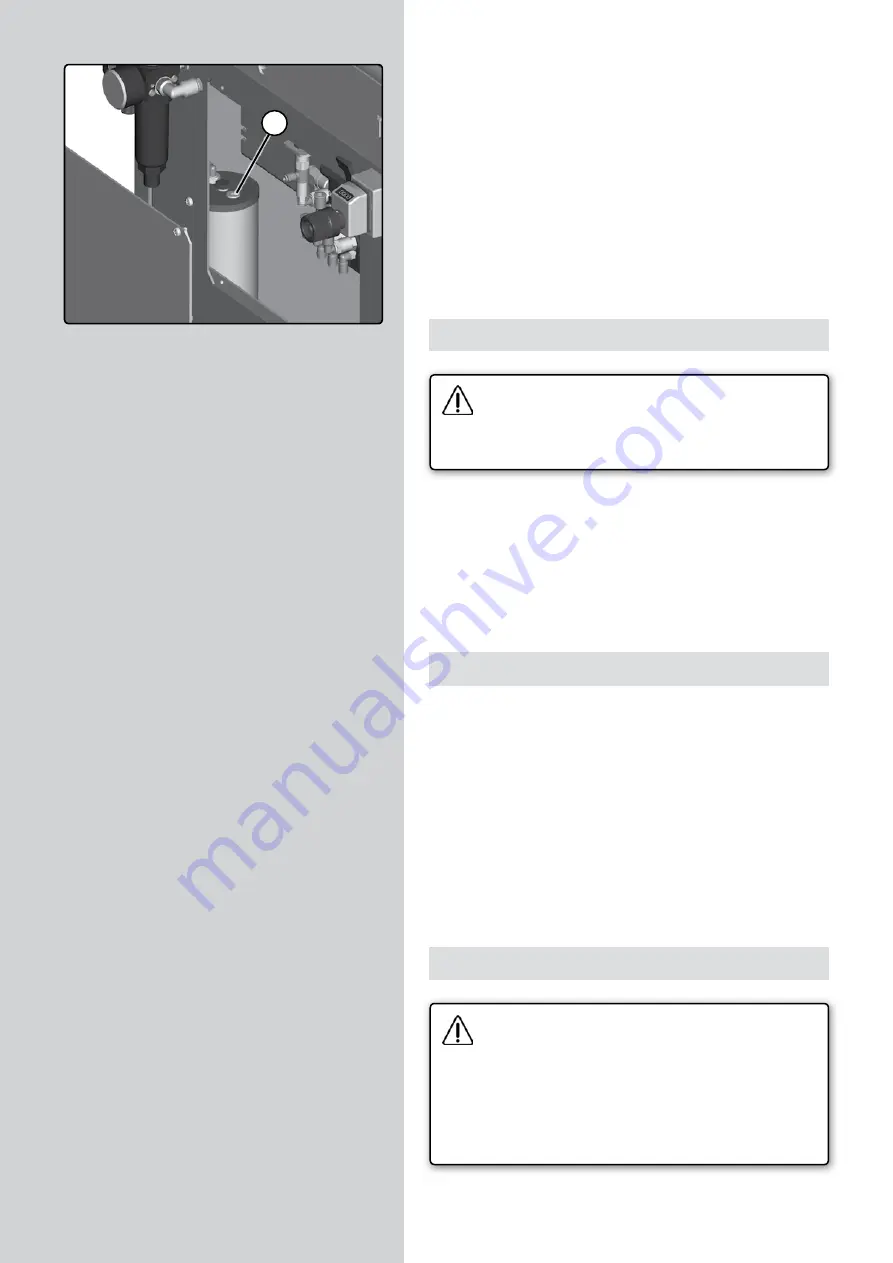

Open the protective pneumatic components cover as explai-

ned in section 8.2.

Loosen the filler cap F (Fig. 29) and with the aid of a funnel

fill the tank to approximately

¾

full.

Replace the sealing cap and fit the motor cover.

CAUTION

Only use oil for hydraulic circuits.

9.

GENERAL CLEANING

Eliminate the pressure from the installation by

disconnecting the safety valve and locking it

with a padlock, then setting the main switch to

0 (zero), locking it with a padlock.

After each operating cycle, carefully clean the machine and

all its parts, vacuuming any shavings and dust.

Use compressed air only when it is truly necessary, wearing

protective goggles and a face mask.

Keep clean, removing any shavings from the work bench.

10.

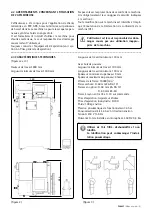

INSPECTING SAFETY DEVICES

The safety of the machine is a direct result of the effective-

ness of the safety devices used.

Inspect the following devices once every two weeks:

• Make sure that the safety microswitches described in sec

-

tion 2.4 work correctly.

• Ensure that the motor stops when the operating pedal is

released.

11.

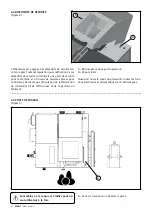

SCRAPPING THE MACHINE

This operation must be performed by expert

operators, while respecting current laws re-

garding workplace safety. Do not dispose of

non-biodegradable products, lubricating oils

or non-ferrous components (rubber, PVC, re-

sins, etc.) into the environment. The destruc-

tion must follow current laws in this regard.

(Figure 29)

F

PAE85T

/ Operating instructions - 45

Summary of Contents for PAE85T

Page 71: ......