13

off. The switch must be set back into the stop position

before turning on the tool again.

Progressive start up.

It allows the tool to be started at low speed and increase

speed gradually. The axle turns on and speeds up gradually

without jerking until the set speed is reached.

Constant speed.

The turning speed remains constant regardless of the

pressure on the working surface. Constant turning speed

ensures optimum sanding quality.

Speed selector.

The speed selecting knob 17 allows the user to select

the appropriate turning speed (it can be changed even

during operation). The user can test and select the desi-

red working speed depending on the working material.

If you have been operating this tool at low speed for

a long time, 3-minute cooling time should be allowed.

To cool the machine down, set the speed selecting knob

at the top speed position and make the tool work idle.

9. RECOMMENDED USE FOR THIS POWER TOOL

Choose the right brush.

Select the most appropriate brush (nylon, metal, sand

paper…) for the job.

The intended use for each brush type should be indi-

cated on its packaging. You may also ask your supplier

for guidance.

General recommendations.

Turn on the tool and let it turn at the selected speed.

Then, slowly bring the brush 26 onto the working piece.

Do not apply exceeding pressure on the tool. Excess of

pressure will not produce better results and you may

cause the motor to overload as well as premature brush

wear. Move the tool at moderate constant speed. Do not

make sudden movements or fluctuations. It is strongly

recommended that you make a test on a trial surface

in order to determine the recommended turning speed.

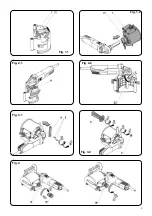

Regulate the position of the wheel 12 as the brush is

being worn out (Fig. 5).

10. MAINTENANCE

Unplug the machine from the main before

starting any maintenance procedures.

Tool cleaning procedures.

For a long life of this tool, it must be properly main-

tained and cleaned.

When working with metal, conducting dust may gather

inside the tool. Blow compressed air through the vent

slots 1 to clean this tool regularly. When working with

resinous materials, dust may stick onto some of the tool

parts. For that type of jobs, it will be necessary:

- To verify that the inside of the protective guard 7

is clean.

- To keep the rollers 12 and 15 clean. Their surface must

be clean, and they must rotate freely.

- Check that the dust exhaust outlet 16 is free from

any obstructions.

- Check the vent slots 1, particularly at the lower part

of the tool and remove any obstructions.

Properly clean the above-mentioned components and

remove any obstructions as required.

11. OPTIONAL ACCESSORIES

6291214 nylon roller for satin finish

6291216 Sand paper flap wheel for metal sanding

6291217 Scotch wheel for metal polishing

6291215 Metal wheel for deburring old hardened wood

1746245 5 m dust collector coupling

6446073 2.25 m dust collector coupling

12. NOISE AND VIBRATION LEVEL

The noise and vibration levels of this device have been

measured in accordance with European standard EN

60745-2-3 and EN 60745-1 and serve as a basis for

comparison with other machines with similar applications.

The indicated vibration level has been determined for

the device’s main applications and may be used as

an initial value for evaluating the risk presented by

exposure to vibrations. However, vibrations may reach

levels that are quite different from the declared value

under other application conditions, with other tools or

with insufficient maintenance of the electrical device

or its accessories, reaching a much higher value as a

result of the work cycle or the manner in which the

electrical device is used.

Therefore, it is necessary to establish safety measures

to protect the user from the effects of vibrations,

such as maintaining both the device and its tools in

perfect condition and organising the duration of work

cycles (such as operating times when the machine is

subjected to loads, and operating times when working

with no-load, in effect, not in use, as reducing the

latter may have a considerable effect upon the overall

exposure value).

13. WARRANTY

All VIRUTEX power tools are guaranteed for 12 months

from the date of purchase, excluding any damage which

is a result of incorrect use or of natural wear and tear

on the machine. All repairs should be carried out by the

official VIRUTEX technical assistance service.