5

head of the machine at an angle, is supplied with the UC317S device.

To mount the 1746268 special template guide on the router (Fig. 7), you

must insert it from the bottom. There is no need to remove the screws

and washers (P). Once in the centre, turn it to place it in its secured

position. Tighten the screws (P) firmly into this position.

5.6. MOUNTING THE ROUTER

Rest the router on the base of the channel routing device and position

the equipment in the appropriate operating direction.

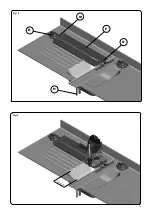

Insert rod (Q) (Fig. 8) into the holes on the base of the router, ensuring

that the two stops (R) are in place on both ends of the base and the

tightening studs face outward (Fig. 8). Next, insert the ends of the

rod into the hole and the groove located on the sides of the channel

routing device. Using the service key, tighten the fastening screw (S)

and the two stops (R) in the correct support position for the channel

routing device (Fig. 8).

To make the operation more comfortable, one of the handgrips (T)

may be removed from the router and placed on the front of the

machine (Fig. 8).

5.7. PREPARING THE UC317S CHANNEL ROUTING DEVICE

CHANNEL LENGTH: The maximum channel length that can be milled

with this device is 400 mm. If you wish to make channels or any other

type of grooves that are shorter in length, loosen the stops (R) and slide

them to the desired measurement (Fig. 8). Use the regulation found on

the channel routing device as an indicator for moving the stop (R).

The centre position of the cutting bit at the beginning and the end of

the maximum milling path is indicated by the position arrows, located

in each of the operating directions. The arrows only indicate the centre

of the cutting bit when the machine is in the vertical position.

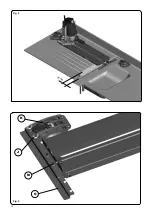

CHANNEL SLOPE: To adjust the height of the channel routing device,

unlock the four locking screws (U) using the service key and raise or

lower the channel routing device by hand until it reaches the desired

height (Fig. 9). Retighten the four screws into the desired position.

With the channel routing device at its highest position, the difference

in height between the beginning and the end of the channel is 4 mm

if a 400-mm channel is made. The required channel slope must be

determined according to the part thickness and the channel length,

using the graduated ruler found on both sides of the equipment as

a guide (Fig. 9).

CUTTING DEPTH: After determining the slope of the channel, the cutting

depth must be set on the milling machine, following the instructions

found in the operating manuals for the FRE317VD router.

Rest the machine on the surface of the channel routing device on its

shortest side and adjust the tool blade until it is perfectly flush with

the part to be worked on (Fig. 8). Secure the machine in this position

with the locking lever (V) (Fig. 8). Loosen the fastening knob (W) and

lower the depth rod (X) until it presses against the lower step of the

revolving turret (Fig. 8). The entire fine adjustment rod (Y) must be

located on the exterior in order to make use of its entire distance. The

nut and locking nut (Z) must be positioned a few millimetres above

the lower stop to enable later adjustments to be made. In this position,

turn the fine adjustment depth indicator A1 (Fig. 8) until position

“0” matches the reference mark. This will be the starting position,

indicating the point at which the cutting bit comes into contact with

the material. Secure the adjustment rod firmly in place with fastening

knob (W), release the locking lever (V) and leave the machine in its

resting position.

Adjust the desired cutting depth of the tool, moving the fine adjustment

rod (Y) up by turning the fine adjustment knob (A2). A full turn of the

knob moves the fine adjustment rod 1 mm, with a maximum distance

of 5 mm. Each division in the gauged fine adjustment indicator (A1)

represents an advance of 0.1 mm.

Once the equipment is ready, move the machine to its starting position

at the beginning of the channel. Start up the machine and lower the

cutting tool until the rod presses against the revolving turret, and

then lock the height of the machine with the locking lever (V). For

absolute safety, the machine must be secured using the A3 nut and

left to right, the minimum distance from the rail to the inside edge of

the sink is approximately 60 mm (Fig. 4).

Once you have determined the correct position of the rail, fasten it to

the part with suction pads or clamps, as appropriate.

5.3. FASTENING THE RAIL TO THE COUNTERTOP

WITH CLAMPS: To fasten the rail to the countertop, we recommend

using the clamps (H) provided with the UF317S/UFN317S accessory.

Insert a clamp into the slot of the rail through one end, move it closer

to the part and fasten it at the edge (Fig. 1 and 2).

WITH SUCTION PADS: The rail may also be fastened onto the countertop

using suction pads (I), but only when the surface of the part is flat,

smooth and non-porous (Fig. 1 and 2). To mount the suction pads on

the rail, insert the screws into the groove provided and fasten it with

wing screws (J) (Fig. 1). We recommend mounting the suction pads near

the edge of the rail. The suction pad works by pressing it down onto

the surface on which it is to be attached and moving the central lever

to the horizontal position. If the work is not performed continuously,

with long breaks in between, it will be necessary to check the suction

of the cups before resuming work.

5.4. SECURING THE CHANNEL ROUTING DEVICE

Before moving the template equipment into position in order to mill

the first channel, you must determine whether you have enough space

on the dish drainer to fasten it in place by applying a suction pad (K)

directly onto the base of the channel routing device (Fig. 2).

If so, place the suction pad on the base of the template assembly and

fasten it using screws (M) (Fig. 2). To mill the first channel, loosen the

tightening knob (E) (Fig. 1) and position the template equipment over

the centre of the sink, sliding the fixing clamp on the rail. Use the

pointer of sight (N) on the fixing clamp as a reference when moving

the equipment along the millimetre ruler (B) (Fig. 1). Tighten fastening

knob (E) firmly. Next, lock the equipment in place by pressing suction

pad (K) down on the surface of the part and lift its central lever to

the horizontal position (Fig. 2).

SUCTION PAD ADAPTER: On small-sized countertops, if you do not

have enough space to place the suction pad directly on the base of

the channel milling machine, you may secure the equipment in place

with the suction pad found on the side of the channel routing device

and using the suction pad adapter (O) (Fig. 5). To do so, secure it firmly

in place using screws (M) and place the suction pad (K) on the side

of the adapter located on the inside of the countertop. Use the wing

screws (J) (Fig. 5) to fasten the suction pad to the adapter (O) (Fig. 5).

If you are using the suction pad adapter (O) to secure the equipment,

we recommend that you operate the machine from right to left in

order to make better use of the space. To do so, you must mill the first

channel in the position closest to the outer edge of the sink in order

to ensure that the machined channels never interfere with the grip

of the suction pad (Fig. 6).

Before proceeding to mill the channels, make sure that

the accessory is firmly attached to the countertop at

all working positions.

5.5. PREPARING THE ROUTER

The most appropriate cutting tool for milling the dish drainer channels

is the 1740324 10-mm R corner trimmer that is provided with the

FRE317VD router, or the optional 1740322 5-mm R trimmer. To use

this cutter bit, hold the head of the milling machine at an angle of at

least 10º, following the instructions in the operating manual for the

FRE317VD router.

With the machine at a 10º angle, mount the selected tool, following the

instructions found in the operating manual for the FRE317VD router.

The FRE317VD router is guided along the UC317S equipment by the

1746268 special template guide, with a diameter of 30 mm and open at

the front. This template guide, specially designed for operating with the

Summary of Contents for UC317S

Page 19: ...19 Fig 2 K H M Fig 3 170 mm F G ...

Page 20: ...20 Fig 5 Fig 4 60 mm K J M O ...

Page 21: ...21 Fig 6 Fig 7 P ...

Page 22: ...22 Fig 8 R Q T X A1 A2 A3 V Z U Y W S Fig 9 U ...

Page 23: ...23 Fig 10 Fig 11 ...