12 / 32

eco-PEN600

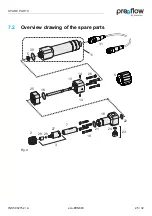

3

Product description

The dispenser has been developed and tested for precision dosing of materials ranging from

low to high viscosity with extremely high repeat accuracy.

preeflow dispensers are positive displacement pumps. The conveying elements comprise a

rotating part, the "rotor", and a stationary part, the "stator". The rotor, which is in the form of

a type of knuckle thread, rotates inside the stator, which has one more thread turn and twice

the pitch length of the rotor. As a result, conveying areas are produced between the stator

and the rotor rotating inside the stator. The rotor also moves radially within the stator.

The conveying spaces move forward continuously due to the movement. The flexible shaft

used to drive the rotor compensates for the eccentric movement of the rotor and is completely

maintenance-free.

The sealing effect of the conveying elements of the dispenser is dependent on the viscosity

and pressure.

Since the direction of flow is reversible, the material can be sucked back to allow a clean

thread break.

The dispenser can be dismantled very quickly.

Together with the eco-CONTROL EC200 dosing control unit, the dispenser forms a dosing

system which is typically installed in a dosing station. The dosing control unit controls the

required parameters (e.g. dosing quantity, dosing speed, etc.).

4

Operation

4.1

Initial commissioning

All activities described below may only be carried out by qualified staff.

When delivered, the stator is not installed so as to avoid bearing damage to the elastomer of

the stator.

Preparation

Undo the cap nut (2).

Pull off the end piece (3).

Plug the star-shaped coupling (5) into the bearing housing (13).

Couple the assembly aid (6) to the bearing housing (13).