Technical Manual

6-32

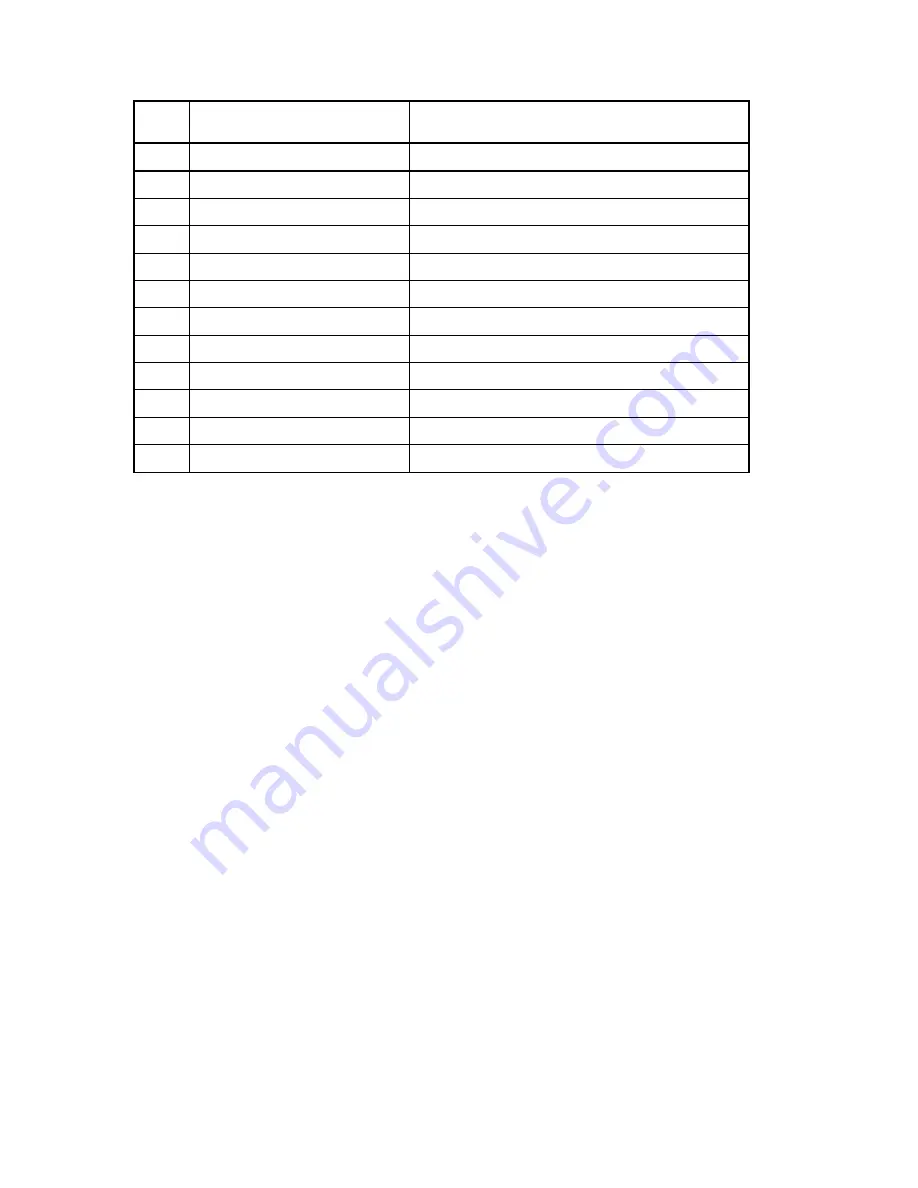

Cmd Action activated in

instrument

Description

122

Activate setpoint 12

See description of setpoint function.

123

Deactivate setpoint 12

See description of setpoint function.

124

Activate setpoint 13

See description of setpoint function.

125

Deactivate setpoint 13

See description of setpoint function.

126

Activate setpoint 14

See description of setpoint function.

127

Deactivate setpoint 14

See description of setpoint function.

128

Activate setpoint 15

See description of setpoint function.

129

Deactivate setpoint 15

See description of setpoint function.

130

Activate setpoint 16

See description of setpoint function.

131

Deactivate setpoint 16

See description of setpoint function.

132

Activate setpoint 1-16

See description of setpoint function.

133

Deactivate setpoint 1-16

See description of setpoint function.

Summary of Contents for G4

Page 2: ......

Page 18: ...Technical Manual 1 14 ...

Page 39: ...G4 Multi Channel Weighing Instrument 3 7 ...

Page 104: ...Technical Manual 5 18 ...

Page 158: ...Technical Manual 6 54 ...

Page 178: ...Technical Manual 7 20 ...

Page 186: ...Technical Manual 8 8 ...

Page 196: ......

Page 197: ...G4 Multi Channel Weighing Instrument Appendix 1 ...

Page 198: ...Technical Manual ...

Page 199: ......