VE810 Series 4 User Manual

70

© 2015 Vision Engraving Systems

4.3

Burnishing

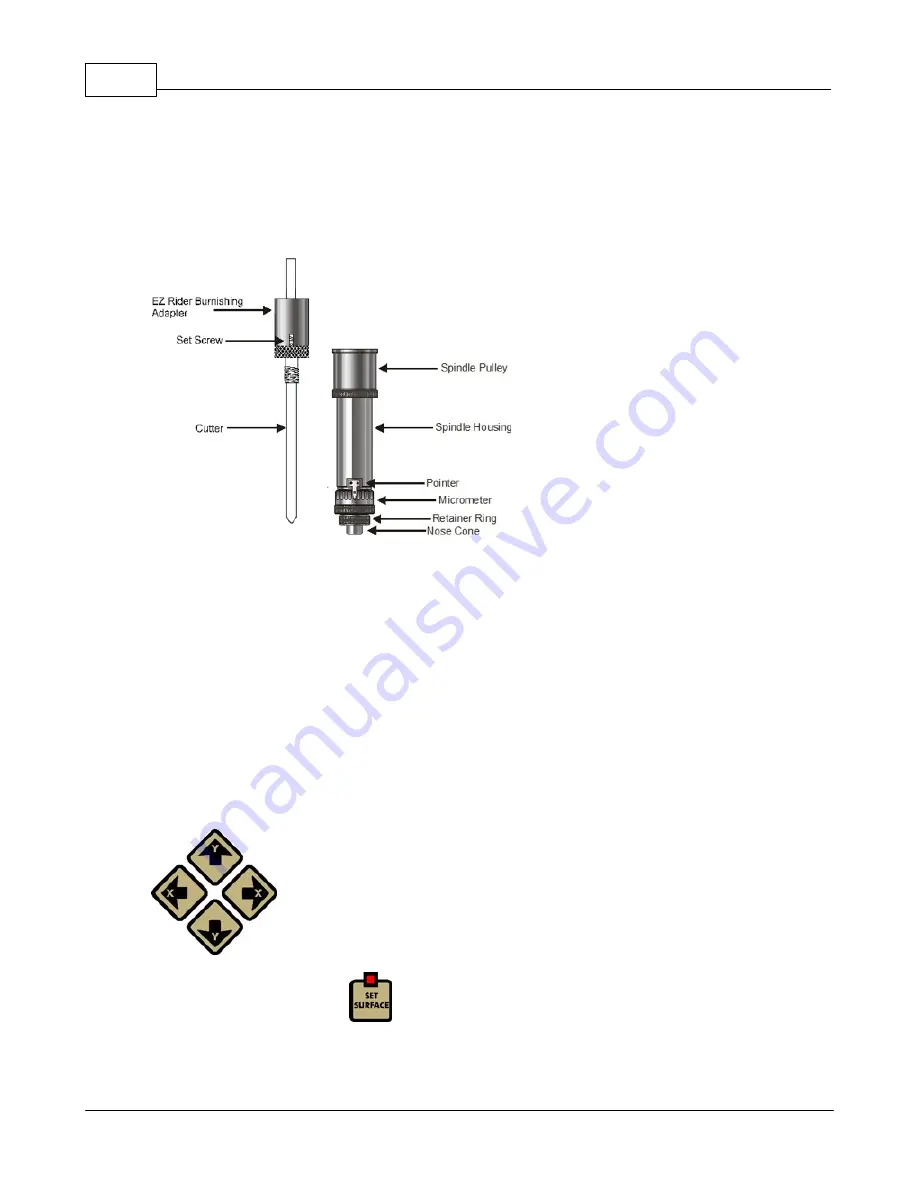

In this section, we will set up to engrave with a burnishing cutter. The figure below shows the Vision

VE810 spindle with a burnishing cutter and an optional EZ Rider burnishing adapter.

The Vision VE810 spindle with burnishing cutter

Burnishing is different than standard rotary engraving mainly because the nose cone is not used to set

the depth of cut. Burnishing does not actually cut deep into metals, rather it cuts the painted surface off

of metals. To effectively burnish, it is recommended to use an optional EZ Rider burnishing adapter.

This helps to control the pressure of the cutter applied to the material. Burnishing requires less

pressure than other types of engraving and the EZ Rider attachment applies the proper amount of

pressure for burnishing.

Installing the EZ Rider is similar to using a cutter knob. First, screw the EZ Rider into the top of the

spindle hand tight. Next, insert the cutter through the EZ Rider and spindle so that the cutter sticks out

below the nose cone approximately 1/8 inch (3 mm). Tighten the set screw in the EZ Rider to hold the

cutter in place.

In order to set the engraver up for burnishing, we will need to perform a "Set Surface" function.

Turn

the machine on and place the material on the table. Use the X,Y Jog Buttons to move the spindle over

your material.

Press the Set Surface button.

The LCD screen will display the message below for approximately

3 seconds. NOTE: The Set Surface button will flash green.