2

7)

Carefully set unit in place, inserting the plenum through the opening.

Install (4) 3/8-16 x 1 ½” bolts, Flat washers, and lock washers to secure the

unit. Tighten bolts to 25 lb-ft.

8)

Trim the headliner or wall to clear Distribution Plenum. Reinstall

headliner or inside wall. Trim around air plenum as required.

9)

In vertical mount change Pressurizer Cover Louver to # 16-40-1108K

This will keep water out.

REFRIGERANT and HEATER HOSE INSTALLATION

1.

Refrigerant hoses should be routed over the top of the cab and down the back or side wall to the

compressor. For vehicles where the cab tilts or moves relative to the compressor ensure that the hoses

will not bind or kink in any possible cab position. Secure hoses so they will not chafe or become damaged.

Hoses must not come in contact with hot vehicle components; exhaust manifolds etc. Check to insure

hoses will not be subject to mechanical abrasions.

2.

A #12 suction hose is recommended for hoses over 10ft.

3.

On units that have the optional heater attach hoses to the unit as shown below. Secure heater hoses

along the refrigerant hoses.

4.

Route drain tubes over top of cab secure with clamps or tie-wraps. Be sure drain hoses are at no point

higher than where they leave the air conditioner. Do not let condensate drip on stairs or walkways where

it could cause a slip hazard.

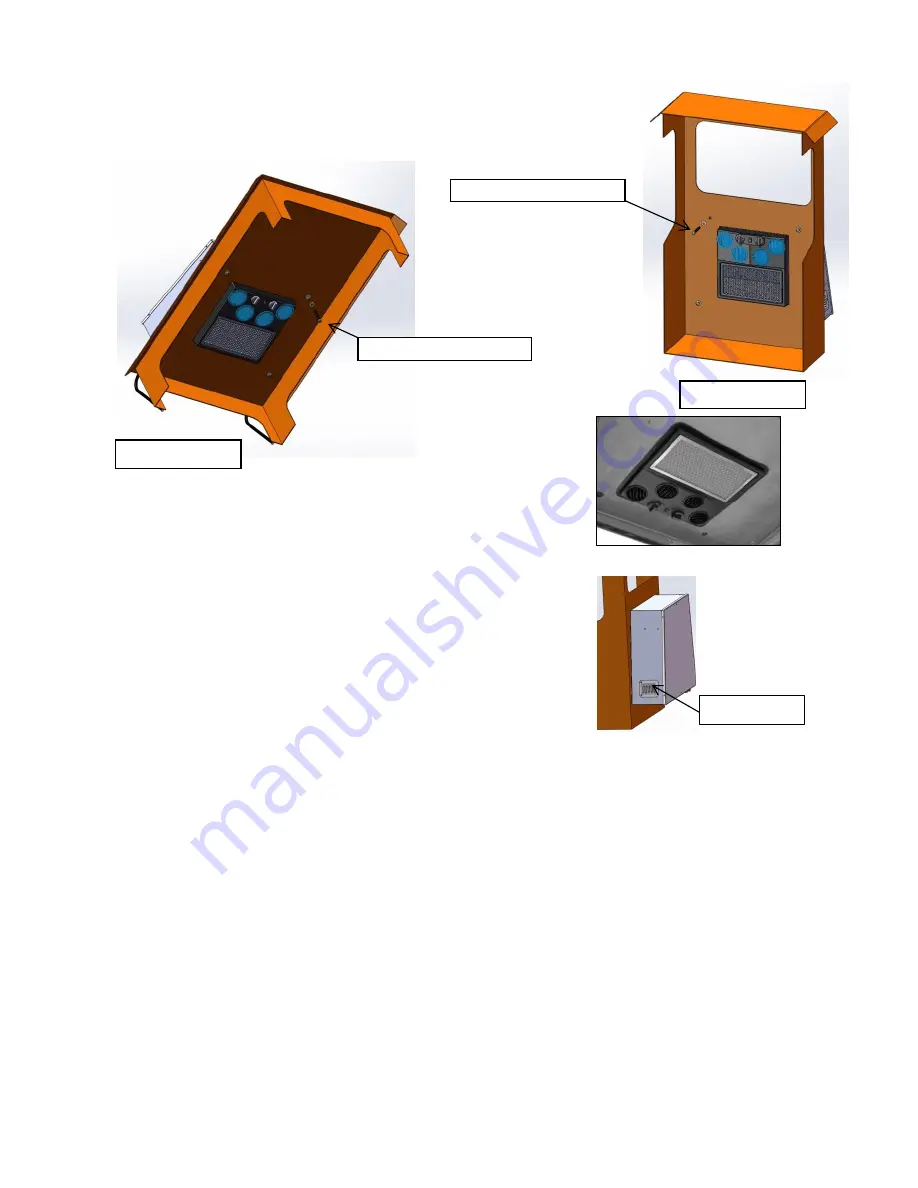

ROOF MOUNT

WALL MOUNT

(4) 3/8”- 16 x 1 ½” BOLT & WASHERS

(4) 3/8”- 16 x 1 ½” BOLT & WASHERS

16-40-1108K