6

●

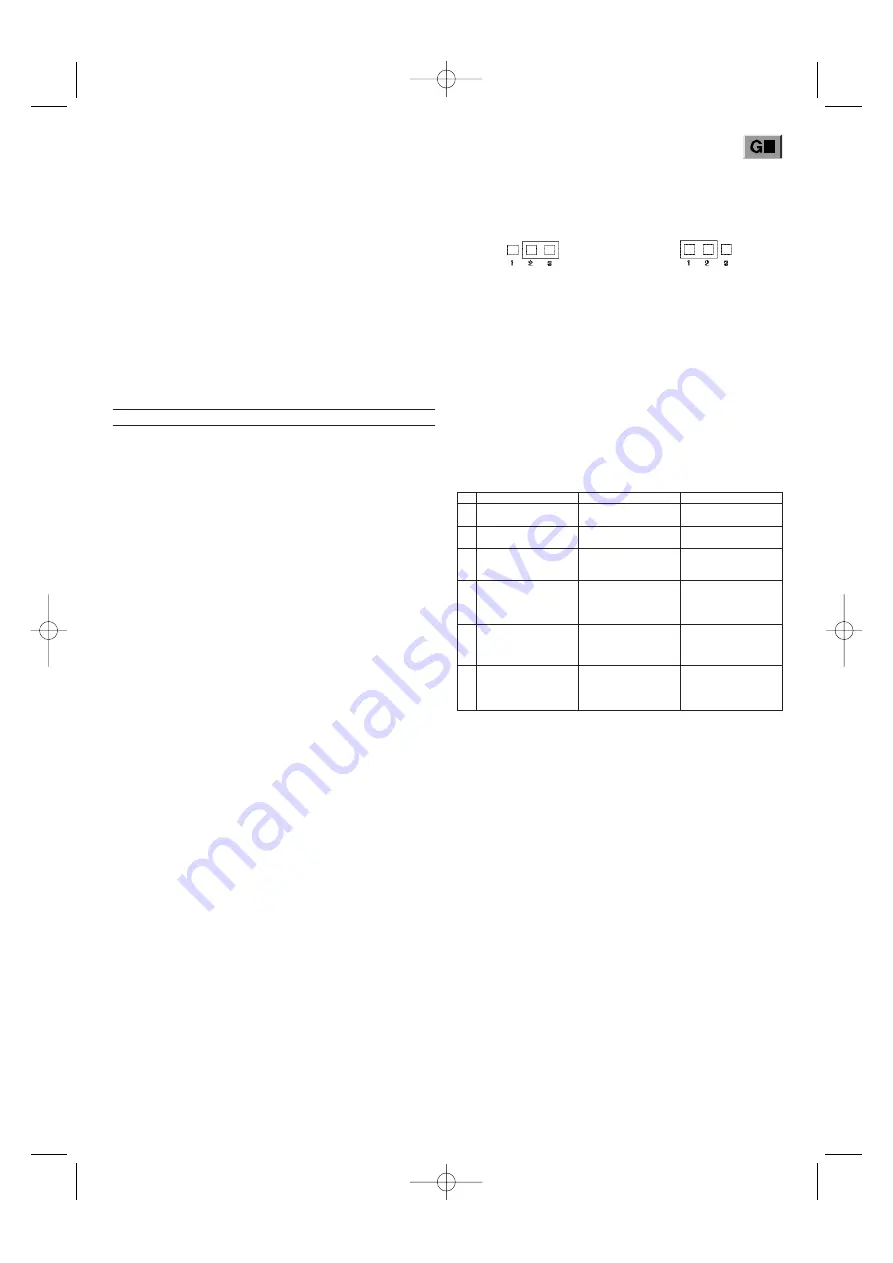

Return step function:

Short appr. 10 ms = Jumper on 2+3

Long appr. 70 ms = Jumper on 1+2

T

VERSION WITH OPTIONAL FUNCTIONS, CONNECTION FOR

SAFETY CONTROL:

●

room for an additional connection on the block terminal of the control

unit.

W ARNING! The bridge at terminal 1+2 must be connected whenever

no safety control unit is installed. If you connect a safety device

take out the bridge at terminal 1+2.

Plug-in 1 + 2

Safety terminal (light barrier or DW function)

1: safety; Signal (SIG) 2: safety; Frame earth (GND)

Plug-in 3 + 4

+ 24V-output, 1 A max. can be used to power a light

barrier for example

3: supply; + 24 V

4: Frame earth (GND)

Plug-in 5 + 6

terminal for warning light, 24 V, max. 1 A

5: + 24 V

6: Frame earth (GND)

Additional possible settings available by means of DIL-switch:

DIL DESCRIPTION

POS OFF

POS ON

1

Reaction on safety device

No reaction

Stop

in direction door open

2

Reaction on safety device

Reversion

Stop

in direction door close

3

Reversion in direction

door close (DIL 2 and

Short (appr. 10 cm)

Open complete

Pos OFF

selected)

4

W arning light flashing

W arning light has no

W arning light flash

in door movements

inherent flashing function, by itself

the flashing must be

done by the control unit

5

Motor delay of 2 sec.

and warning light can

Off

O n

flash twice befor the

door moves

6

Backjump. Door in

closed position, the

Short

Long

operator moves in the

appr. 10 ms, 0-1 mm

appr. 10 ms, 1-5 mm

open direction

DEALING WITH OBSTRUCTIONS

●

If the door encounters an obstruction when it is closing, the drive rever-

ses approx. 10 cm and then stops in this position. For reasons

of safety, the next starting signal causes the door to move only in the

Open direction, until the upper end-point in its travel has been reach-

ed. At this point, both directions of travel are enabled again. The same

applies in the opposite direction for any obstruction encountered during

opening. If the door should come up against an obstruction in both

directions, for reasons of safety the drive mechanism switches over to

dead-man operating mode, i.e. the light flashes and the drive only

operates for as long as the wall-mounted control button is held down.

Once the obstruction has been cleared, the door can be brought to one

of the end-points of its travel in dead-man operating mode. At this point

the drive returns to its normal operating mode.

CARE AND MAINTENANCE

●

Chains and tracks that become very dirty should be cleaned with a

clean cloth.

●

Lubricate the chain once a year with chain lubricant e.g. WD 40.

●

Check that all screws and bolts are tightened. Tighten, additionally,

where necessary.

●

Check the safety control every four weeks.

●

Check the door springs each year.

DISASSEMBLY

●

The sequence of operations is identical to that described in the Section

entitled Installation but in reverse order.

●

The setting procedures described are not applicable.

W ARRANTY AND AFTER-SALES SERVICE

●

If you require after-sales service, spare parts or accessories, please

contact your specialist retailer.

Important: - In the event the main cable to the 800 N tractive force

drive becomes damaged, the equipment should be sent to the manu-

facturer (the main cable is not replaceable).

Thank you for buying an X-pervisio unit. We are sure you will enjoy many

years of reliable service.

●

On the LIMIT OF POWER potentiometer (19), the upper limit of tole-

rance can be set. This is the amount of power, in addition to the pro-

grammed power, which may be applied, in order to open or close the

door. The maximum power between the door and the case may not

exceed 150 N. At the left stop bolt of the potentiometer, the additional

tolerated power is approximately 1.5 kg; at the right stop, it is 18 kg.

W ARNING ! For your own safety, the power tolerance should be kept

as low as possible to ensure that any obstruction s are recognized

rapidly and safely.

P

●

Check that the driver system can be stopped during opening and clos-

ing movements, by a light press of the hand against the door, at

a height of 100 mm above floor level. During the descending move-

ment, the drive system should change direction, moving the door

approximately 100 mm in the opposite direction.

N.B: Garages with only one point of entry must be fitted with a

bowden cable for emergency unlocking (from the outside) if there

is a power failure.

III. CONTROL UNIT

O

CANCELLING POWER VA L U E S

●

Once the drive has been installed and connected up to the mains

supply, the integrated light flashes indicating that the drive has still not

learned any power values. If the light fails to flash because the drive

has already learned power values e.g. in the course of tests carried

out under no-load conditions these values must first be cancelled.

●

Proceed by prising off the cover (18) over the light using a screwdriver.

Using a narrow-pointed object as a tool, hold down the code relay but-

ton (marked Code ) for approx. 3 seconds. The light begins to flash

as soon as the values are cancelled. Proceed as per the instructions

for Illustration N to teach the required power values. Replace the

cover over the light.

O

CHANGING THE CODE

●

Changing the code is necessary if, for example, a transmitter is lost.

●

Proceed by prising off the cover over the light using a screwdriver.

The code relay button (marked C O D E ) must be held down until the

red LED (marked RADIO ) remains lit and the light goes out (approx.

8 seconds). Holding down the button for a shorter time cancels the

power values already learned.

●

The remote control unit must now be re-encoded as indicated under

Encoding a New Remote Control Unit .

O

CHANGING THE BULB IN THE CONTROL UNIT

●

Pull out the mains cable (6) and loosen the lamp cover, using a screw

driver. Unscrew the bulb by turning it counterclockwise.

●

Screw in a new bulb by turning it clockwise (24 V, 21 W, Ba 15 s).

Q

C H A N G E B ATTERY OF A REMOTE CONTROL UNIT

●

When the battery is almost fully discharged, the control lamp will

flash when the button is pressed. At this point, the battery should

be replaced by a new one of the same kind. Open the remote control,

remove the old battery and insert the new one in exactly the same

position.

●

Check that the poles are properly connected (+/ ).

●

Dispose of the old battery in an environmentally-acceptable manner.

R

PROGRAMMING A NEW REMOTE CONTROL UNIT

●

The remote control unit supplied is factory-programmed with a code

selected at random from a range of ca.16,700,000 possible codes.

It does not require programming by the customer.

●

If you should require an additional remote control, this must be pro-

grammed with your code.

●

To programme the remote control unit proceed as follows: disconnect

the mains supply and unclip the lamp cover (18) with a scewdriver.

Unscrew the two screws on the control panel. Open and pull out the

circuit card.

●

Open up the remote control and fit its contacts into the corresponding

contacts on the circuit card. Press the button to be coded on the remo-

te control until the control lamp on the circuit card goes out (approx. 2

3 secs.). Reverse the procedure to reassemble.

S

VERSION WITHOUT OPTIONAL FUNCTIONS

The degree of back-jump on the gates after closing can be

adjusted.

Aperto old french[047]dutch.qxd 3/07/01 12:05 Pagina 6