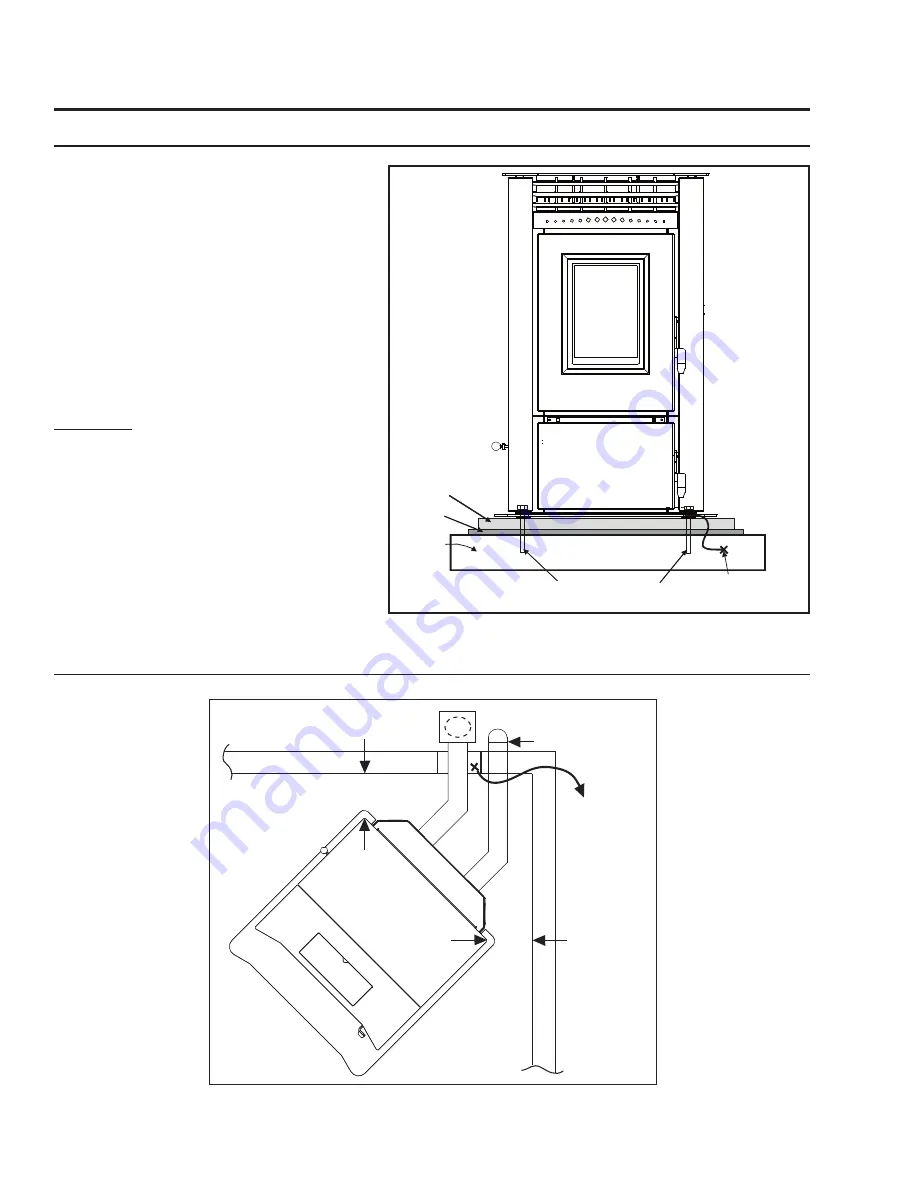

Figure 10: Corner Installation.

Installation

M

OBILE

H

OME

I

NSTALLATION

:

4"

(10cm)

4"

(10cm)

Fresh Air Intake

Wall thimble

manufactured

by pellet vent

manufacturer.

1

/

4

” Lag Bolts Securely

Fastened

Ground Wire Directly

to Metal Chassis

Optional

Hearth Pad

Flooring

Steel

Frame

● Secure the heater to the floor using the

four (4) holes in the pedestal.

● Ensure the unit is electrically grounded to

the chassis of your home (permanently).

● Do not install in a room people sleep in.

● Outside fresh air is mandatory. Secure

outside air connections directly to fresh

air intake pipe and secure with three (3)

screws evenly spaced.

CAUTION: THE STRUCTURAL

INTEGRITY OF THE

MANUFACTURED HOME FLOOR,

WALL AND CEILING/ROOF MUST

BE MAINTAINED.

C

ORNER

T

HROUGH

W

ALL

I

NSTALLATION

:

Figure 9: Mobile home installation.

10