Instructions for Use

28

7

Advanced Set-up Features

The Co-mix unit also provides a number of advanced features which allow

the user to optimise the unit’s performance to meet their individual needs.

7.1

Mixer Program Tools

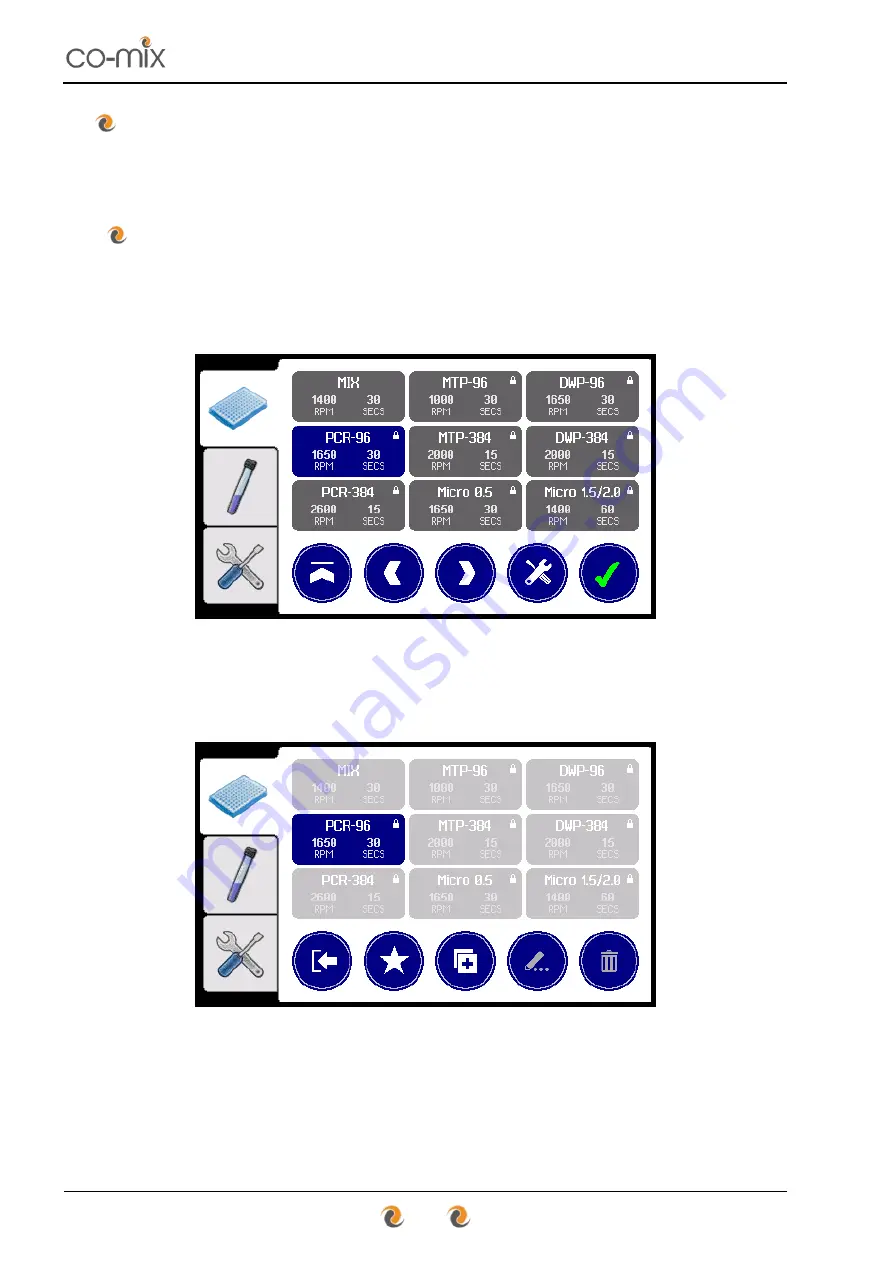

As well as the pre-defined mixing programs, the user can create variants of

the existing ones. This allows new programs to be developed and optimised

for the specific plate type, sample assay and fill volume being used.

Home Previous Next

Tools

Accept

From the

Mixer

program selection screen, highlight the program to be copied

or modified and then press the

Tools

button.

Exit Favourite New

Edit

Delete

The tools menu options are summarised in Table 10 and explained in detail

in the following sub-sections.

Summary of Contents for Co-mix

Page 1: ...Instructions for Use...